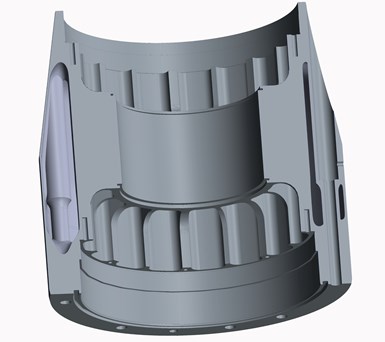

The housing will contain a generator capable of 30 kW. Internal cooling passages made through 3D printing allow the housing to be made from aluminum rather than a more heat-resistant material.

KW Micro Power of Miami, Florida, is developing a microturbine generator that company president Enrique Enriquez expects to deliver the highest power density ever realized in a generator of this class. The 30-inch by 15-inch-diameter generator coming to market soon will be capable of 30 kW, an output that today might require a device around twice these dimensions. Additive manufacturing is essential for producing the intricate components that allow a large power output from a small volume. And because AM is also enabling lightweighting of the same components, the 150-pound generator will offer a previously unattained power-to-weight ratio as well, Enriquez says.

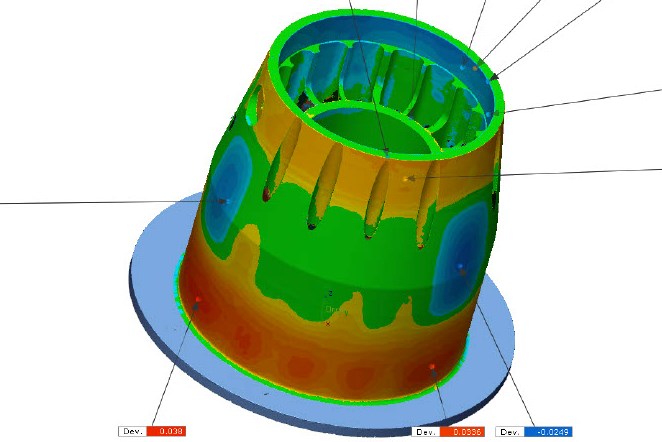

Load analysis of the housing revealed where material could safely be removed. Large internal spaces printed into the housing design allow fuel to flow through it and reduce the part's weight by 10 pounds. Image: KW Micro Power

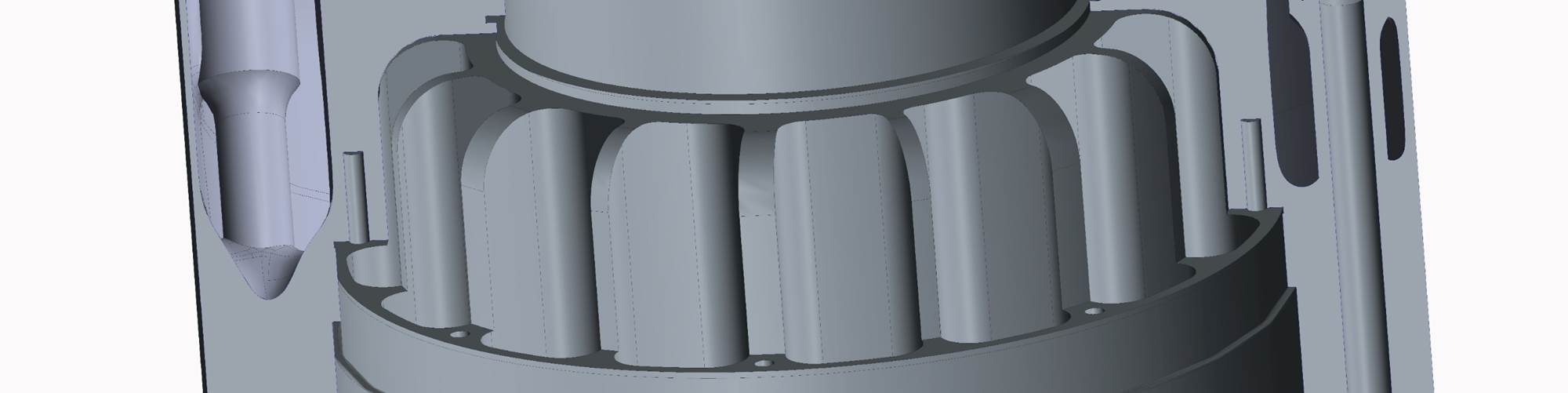

The company has gone component by component through its generator design looking for engineering wins it could achieve through AM. An earlier success involved a 10-inch-diameter ring-shaped component with elaborate internal passages for channeling exhaust gas. Now, the component seen here is an even bigger success — bigger in terms of volume, and in terms of the many interrelated benefits the additive design achieves. This housing for the turbine features internal passages and large internal spaces not only for lightweighting, but also for cooling the system and preheating the fuel by passing the fuel through the housing structure.

Enriquez says, “How do you raise the power efficiency? Stop letting parasitic losses get away.” When a generator gets hot, this means energy is being lost to heat rather than work. Flowing the generator’s fuel through open passages in the housing allows the fuel itself to capture that energy. The fuel gets preheated from room temperature to 130°F, reducing the additional energy needed for combustion. Meanwhile, subtracting mass from the housing by adding the internal passages and cavities reduced its weight from 23 pounds for the original solid housing design to 13 pounds, while the cooling effect saves cost. Running cooler allows the housing to be made from an aluminum alloy (F357) instead of a more expensive heat-resistant material.

Wagner Machine produced the part. Holding the part is company CEO Kurt Wagner.

Software from nTopology was used to create the housing design. Load modeling determined where material could safely be removed. The software generated a hollow shell design with variable wall thickness, and it smoothed the internal geometry to ensure it could be 3D printed without support structures. Wagner Machine of Champaign, Illinois, made the part for KW Micro using a Sapphire laser powder bed fusion system from Velo3D. Wagner, a full-service metalworking contract manufacturer, performed the part’s CNC machining as well.

Aircraft are among the potential applications for the generator — it can serve as an auxiliary power unit where space and weight constraints are critical. But Enriquez says ground-based applications are promising, too. “Instead of a massive 1 MW turbine, what if 30 of these microturbines were daisy-chained to deliver the same output?” Units could then be turned on and off as needed, he notes. There would be significant power available, combined with the chance to generate only the amount of power that is required.

Wagner Machine both 3D printed and machined the generator housing. Additive manufacturing is performed on the Velo3D system in the right half of this photo. Metal AM and CNC machining capability operate side-by-side on Wagner's shop floor. The company has so far produced two of the housings, which KW Micro is evaluating.

How Does Heat Treating Affect a Metal 3D Printed Part?

More on the story above: Distortion measured in the microturbine housing illustrates the kind of effects in additive manufacturing that part design or machining stock allowances can anticipate. READ

Related Content

8 Cool Parts From Formnext 2024: The Cool Parts Show #78

End-use parts found at Formnext this year address various aspects of additive's advance, notably AM winning on cost against established processes.

Read MoreHow Norsk Titanium Is Scaling Up AM Production — and Employment — in New York State

New opportunities for part production via the company’s forging-like additive process are coming from the aerospace industry as well as a different sector, the semiconductor industry.

Read MoreAdditive Manufacturing Is Subtractive, Too: How CNC Machining Integrates With AM (Includes Video)

For Keselowski Advanced Manufacturing, succeeding with laser powder bed fusion as a production process means developing a machine shop that is responsive to, and moves at the pacing of, metal 3D printing.

Read MoreWhy AM Leads to Internal Production for Collins Aerospace (Includes Video)

A new Charlotte-area center will provide additive manufacturing expertise and production capacity for Collins business units based across the country, allowing the company to guard proprietary design and process details that are often part of AM.

Read MoreRead Next

3D Printing the "Impossible" Metal Part

Velo3D’s SupportFree additive manufacturing process helps KW Micro Power turn a geometrically complex design concept into reality.

Read MoreThis 3D Printed Turbine Replaced 61 Parts With 1: Here Is What That Means

Additive manufacturing makes possible a radical microturbine that increases power-to-weight ratio, reduces cost and extends time between overhaul.

Read More3D Printing for Better Flame From a Gas Turbine Swirler: The Cool Parts Show #42

A Penn State gas turbine researcher turns to additive manufacturing graduate students to help face the challenge of swirler optimization.

Read More