Purdue University to Establish Thermwood LSAM Research Laboratory

Collaborative efforts like this can bring together diverse organizations that specialize in different aspects of an emerging technology and often produce results that none of the participants could possibly achieve on their own.

Share

Read Next

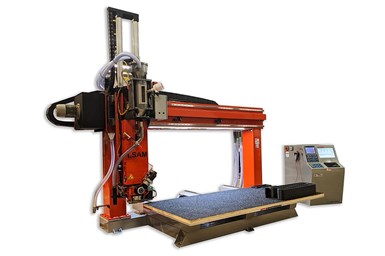

Thermwood LSAM Additive Printer 10'×5'

Purdue University’s Composites Manufacturing Simulation Center (CMSC) and Thermwood Corp. have agreed to establish a large-scale additive manufacturing (AM) laboratory to perform industry-funded research into large-scale composite thermoplastic AM.

The facility will be located in Purdue’s Indiana Manufacturing Institute located in the Purdue Research Park in West Lafayette, Indiana, and will be staffed and operated by Purdue CMSC personnel. The official name for the facility is the “Thermwood LSAM Research Laboratory at Purdue University.”

The laboratory will be equipped with an LSAM 105 (ten-five) large-scale additive printer and a corresponding five-axis LSAM Additive Trimmer, as well as a variety of support systems. This installation is capable of printing and trimming complex geometries up to 5 × 10 × 4 ft. tall at print rates of up to 100 lbs/hr. Commercial maximum print temperature for LSAM printers is usually limited to 450°C. However, this particular system has been modified to enable testing at even higher temperatures for experimentation with innovations in materials normally not used in AM.

This effort will be enhanced with the ability of Thermwood’s LSAM large-scale AM systems to measure and precisely control the temperature of a printed layer at the instant a new layer is deposited. This will support research into the very core of the additive print process and will serve to provide validation of Purdue’s extensive AM simulation capabilities for large-scale AM.

Purdue plans to partner with industry to provide services to enhance, encourage and expand the adoption of large-scale AM for diverse industrial applications. It also plans to work with polymer suppliers to refine formulations and determine the ideal processing parameters necessary to produce the absolute highest quality large-scale printed parts possible.

Related Content

-

Big Metal Additive: The Difference Between a Shape and a Part Is Quality

Preparing to scale directed energy deposition to ongoing full production is not a technological challenge: DED is ready. But it is an organizational challenge, says the company founder. Here is what it means to implement a quality system.

-

Video: AM for Repair of Large Shafts

Wind power shafts that might once have been scrapped are now returned to service. See the robotic directed energy deposition (DED) and shaft preheating system developed by Ikergune, Izadi and Talens.

-

Aircraft Ducts 3D Printed in Composite Instead of Metal: The Cool Parts Show #68

Eaton’s new reinforced PEKK, tailored to aircraft applications, provides a cheaper and faster way to make ducts compared to formed aluminum.