Heat Exchangers

How Additive Manufacturing Is Transforming EVs and Transportation: AM Radio #23

As 3D printing is adopted into the electric vehicle (EV) market, it is not just vehicles that are being reshaped. In this episode of the AM Radio podcast, we discuss additive manufacturing and the future of transportation.

Listen3D Printed Brackets Secure Fuel for Nuclear Power: The Cool Parts Show #45

Can additive manufacturing improve the design of nuclear power plants? These steel brackets are the first step.

WatchVacuum Cycling Nucleation (VCN) Removes Resin, Powders from 3D Printed Parts

Vacuum Processing Systems’ proprietary VCN process is well suited for parts with small holes and tiny passageways. A combination of vacuum and fluid clears uncured resin or unsintered metal powder. See it in action.

Watch3D Printed Heat Exchanger Uses Gyroids for Better Cooling | The Cool Parts Show #43

Replacement heat exchanger for a helicopter is half the size and delivers 4× the cooling, thanks to a geometry that could only be made via additive manufacturing.

WatchA Conversation on Finishing's Role in Additive Manufacturing: AM Radio #12

Conventional finishing techniques like electroplating and powder coating have a role to play in AM. Stephanie Hendrixson and Scott Francis discuss how additive will go farther with finishing on the latest episode of AM Radio.

ListenVideo: Functional Excavator Features 3D Printed Parts

Oak Ridge National Lab's Project AME swapped an excavator's cab, stick and heat exchanger for 3D printed parts. Stephanie Hendrixson and Peter Zelinski get the scoop.

WatchVelo3D Qualifies New Superalloy for Use in Its Sapphire Printers

New nickel-based Höganäs Amperprint 0233 Haynes 282 powder enhances the capabilities of Velo3D’s end-to-end solution for customers in oil and gas, aviation, energy, space and other high-value applications.

Read MoreDesktop Metal Qualifies Pure Copper for Additive Manufacturing

Production System binder jetting technology is said to enable the mass production of high-performance copper parts for automotive, aerospace and electronics.

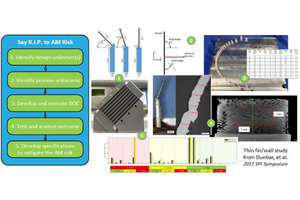

Read MoreHow Thin Can I Make My 3D Printed Part?

Be smart and prototype fast when developing design guidelines for AM.

Read MorePulsed Electrochemical Machining as Postprocessing for AM

Pulsed electrochemical machining is a production metal AM-ready form of postprocessing with short cycle times and long tool life.

Read More