Heat Exchangers

DesktopMetal Introduces Pure Copper for its Studio System

Unlike laser-based processes (which often print chromium zirconium copper), the Studio System’s Bound Metal Deposition process is able to print pure copper, unlocking the full benefits of the material.

Read More26 Steps Vs. 9: The Metal AM Case for Mission Critical Parts

Knust Godwin introduced metal AM into its precision-machining environment nearly eight years ago. Now the company is using the capability to break through into new applications and give 3D printed mission-critical parts a renewed business case.

Read MoreOptomec Releases Pure Copper DED Process

Optomec has developed a pure copper Additive Manufacturing process using Optomec’s LENS directed energy deposition (DED) systems.

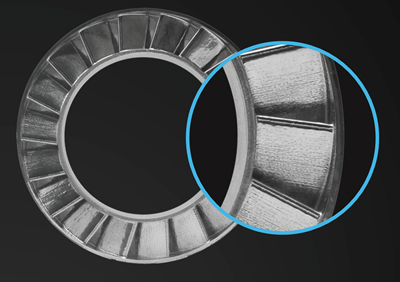

Read MoreVelo3D Collaborates with PWR to Print Next-Gen, High-Performance Heat Exchangers

Together with Velo3D, PWR will explore new high-performance thermal management strategies through metal 3D printing across a range of heat exchanger applications.

Read MoreMission Critical: An AM Breakthrough in Commercial Aviation

The GE9X is the first commercial aircraft engine to reach production with significant additive content. The story of GE’s accomplishment and why it matters.

Read More3D Systems DMP Flex 350 and Factory 350 Systems Designed for Production

3D Systems’ DMP Flex 350 and DMP Factory 350 are designed for production of components for industrial applications such as aerospace, health care and transportation.

Read MoreRoush Uses Engine Cylinder Head to Prove Out Additive Manufacturing

A 3D-printed cylinder head investigation reveals the possibilities of additive manufacturing.

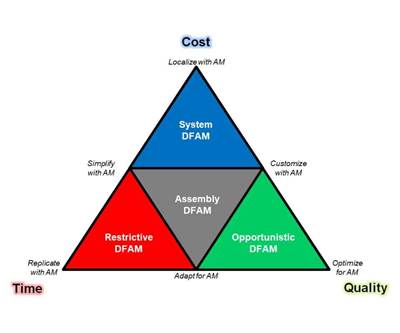

Read MoreFinding the Value Proposition for Additive Manufacturing

Why would anyone want to use additive manufacturing?

Read MoreMetal AM Advances Thermal Management Systems in Aerospace

The aerospace industry is increasingly turning to additive manufacturing for thermal management components. Andrew Carter of Stratasys Direct Manufacturing explains why.

Read MoreDMG MORI Prepares for New Additive Debut in the United States

While the 2018 DMG MORI open house in Pfronten, Germany, did not feature any world premieres in the additive space, all signs point to the Lasertec 30 SLM hitting the U.S. market soon.

Watch