FFF

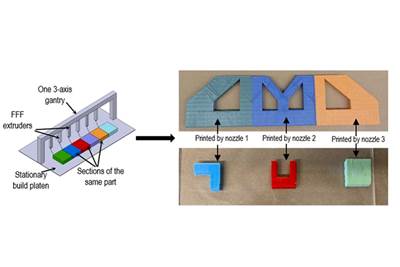

Rutgers Engineers Create Faster, More Precise 3D Printing Process

Researchers says their Multiplexed Fused Filament Fabrication Process could be a game changer for the 3D printing industry.

Read MoreUnusual Forms of 3D Printing, and How to Categorize This Technology: AM Radio #21A

In this episode of AM Radio, Stephanie Hendrixson and Peter Zelinski quiz each other on six 3D printing processes — some common, some novel. Test your own knowledge and stick around for a discussion about how to categorize (or maybe re-categorize) AM technologies.

ListenKimya Supplying Materials for Stratasys’ FDM Systems

Stratasys will offer customers two new materials from Kimya — EN45545–2 certified polycarbon filament (Kimya PC-FR) and a polyetherketone filament made from Arkema’s Kepstan (Kimya PEKK-SC).

Read MoreAudi Creates 3D Printing Filament from Parts Packaging

The German automotive company is among the leaders in material reuse—which includes making filaments from what might otherwise be considered waste.

Read MorePostProcess’ FDM Support Removal Reduces Postprocessing Time

The company says the Vorsa 500 reduces support removal processing times in additive manufacturing by over 50%.

Read MoreFaster FFF Build Rate Using Rectangular, Variable-Orifice Nozzle (Includes Video)

A new nozzle design plus sophisticated slicer software offer control over layer width in polymer 3D printing while the layer height stays constant.

WatchUsing (And Scaling) FDM 3D Printing for Production

Maxwell June’s razor press, which is designed to combine the ease of use of a disposable razor with the environmental and cost benefits of a wet shaving system, is made via FDM 3D printing. How did the company make this choice, and how does it plan to scale up?

WatchMetal Parts Are Now Within Reach for Users of Polymer 3D Printers

An option for accessible metal 3D printing: New metal composite filament from BASF Forward AM has made it easy for Austrian company Sparox 3D to pivot its Ultimaker FFF capacity into metals, without major additional investments in skills or equipment.

Read MoreThe First Choice Was Right: How RP+M Succeeded With Production FDM

This additive manufacturing company narrowed its focus onto the 3D printing capability it knew best and the industry sector best able to benefit from FDM production parts. Characterizing and controlling the process was the breakthrough that has led to production work from Boeing and others.

Read MorePostProcess, Alphacam Partner to Expand Access to Automated 3D Postprinting in Germany

Alphacam’s in-house printing service — which manufactures components with FDM, PolyJet, LPBF, BMD, DLP/P3 and SAF technology — will also utilize the PostProcess solution for its own operations.

Read More