Depowdering

Depowdering Station Automatically Cleans Unused Metal Powder from 3D Printed Build Jobs

The Volkmann additive manufacturing technology is designed to safeguard workers from toxic materials and boost efficiency.

Read MoreAvia Tools' Depowdering Systems for Metal 3D Printed Parts

Aviation manufacturer only landed in the additive manufacturing segment out of necessity in order to address a client’s depowdering issue. Now it has developed a range of system sizes for any 3D printed part up to 1 metric ton and 1.5 m tall.

Read MorePostProcess, EOS Create Partnership for Automated Depowdering

The strategic partnership is designed to enable more sustainable automation through the additive manufacturing workflow.

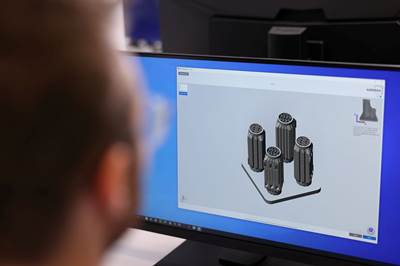

Read MoreSolukon’s SPR-Pathfinder Software for Automatic Depowdering

Formnext: It is said the algorithm-based SPR-Pathfinder calculates the ideal motion sequence for the most complex geometries, finding the best path to enable the powder to flow out completely.

Read MoreGE Additive’s Binder Jet Line Series 3 for High-Volume, Serial Production

The system also enables users to depowder intricate parts without destroying fine features.

Read MoreLauncher Acquires Solukon Depowdering System for Postprocessing Rocket Parts

The depowdering system removes residual and clogged powder from metal laser-melted parts within a sealed process chamber, using adjustable vibration and automated two-axis part rotation while recovering superfluous powder.

Read MoreSolukon Upgrades Automated Powder Removal Units for Large Parts

Systems are now reinforced to handle larger parts and feature a joystick to improve and individualize controlling, and an optional impactor system for breaking up clogged powder bulks.

Read MoreAM Solutions Updates S1 Postprocessing for Depowdering

System ensures postprocessing tasks are handled more efficiently, safer and more consistently.

Read More