Composites-Ready 3D Printers Produce High-Strength Parts

IMTS 2022: Stratasys’ new printers are said to offer high stiffness and strength materials in a hardened machine ready for composite material printing.

Share

Read Next

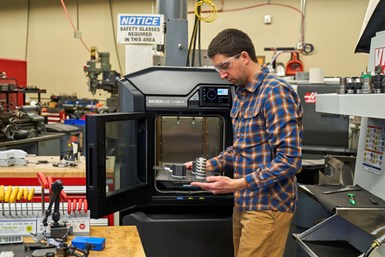

Stratasys has expanded its F123 Series of 3D printers with the introduction of the F190CR and F370CR 3D printers, plus new FDM Nylon-CF10 material reinforced with carbon fiber. The printers are said to offer high stiffness and strength materials in a hardened machine ready for composite material printing.

The composite 3D printers are designed for manufacturers and industrial machinists to supplement traditional fabrication technologies with high-strength composite 3D printing. The printers are said to help manufacturers produce end-use parts faster and more cost effectively, and are well suited for jigs, fixtures and workholding tools.

The company says the printers include integrated GrabCAD Print software that provides a simple, intuitive CAD-to-print workflow and includes advanced features to ensure successful prints. Stratasys also provides enterprise application connectivity through the MTConnect standard and its GrabCAD Software Development Kit.

The printers also include reusable build trays, a built-in camera for remote monitoring and a 7" control touchscreen. The F370CR printer also offers auto-changeover of materials, which means there is no need to interrupt a build to replace materials — a new canister is simply put in place and the build continues.

Related Content

-

Savage Automation Delivers 3D Printed Commercial Manufacturing Aids

The company's approach to designing end-of-arm tooling and other devices has evolved over the years to support longevity and repairs.

-

Advancing Additive Manufacturing With a CATCH and Release Approach

Solutions for energy efficiency, sustainability, part repair and more are developing at Siemens’ Charlotte Advanced Technology Collaboration Hub (CATCH) in North Carolina.

-

Evaluating the Printability and Mechanical Properties of LFAM Regrind

A study conducted by SABIC and Local Motors identified potential for the reuse of scrap reinforced polymer from large-format additive manufacturing. As this method increases in popularity, sustainable practices for recycling excess materials is a burgeoning concern.