Circular Economy

Retraction Footwear Is the Sustainable Manufacturing Business of the Future

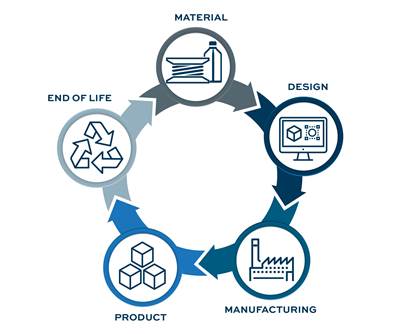

Retraction Footwear offers a new way of buying flip-flops that are made to suit each customer. But the company also represents a new way of thinking about production, in a circular economy loop that encompasses material, design, manufacturing, product and end-of-life.

Read More3D Printing Helps Close the Loop for Armor’s Circular Economy

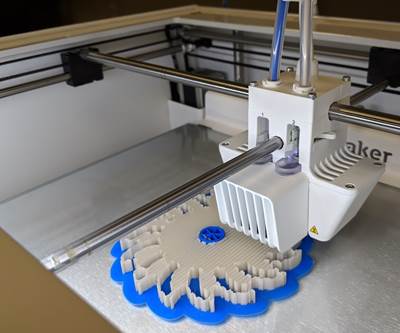

Manufacturing 3D printing filament was first a way for Armor to recycle its own reclaimed plastic waste. But now, this business unit is helping to close the loop on sustainability for plastic 3D printed products.

Read MoreSustainability’s Moment Is Additive Manufacturing’s Moment

The disruption needed by additive manufacturing closely mirrors that required to implement the circular economy. Both can be pursued simultaneously — and the right time is now.

Read MoreAdditive Manufacturing Will Aid And Accelerate The Circular Economy

A circular economy links material, design, manufacturing, product and end-of-life in a continuous, sustainable loop. This special report illustrates the roles for 3D printing every step of the way.

Read MoreAdditive Manufacturing and Sustainability Go Together — Here Is Why

3D printing enables sustainable production through recycled materials, end-of-product-life-cycle solutions, and helping to realize eco-friendly products.

Read MoreAdditive Manufacturer Green Trade Association Commissions Research Project on Sustainability

The Additive Manufacturer Green Trade Association (AMGTA) has selected Jeremy Faludi, Ph.D., a leading researcher of sustainable engineering, to oversee its first commissioned university research project. The project will be a systematic review of the environmental impacts and benefits of additive manufacturing.

Read MoreA Circular Economy for 3D Printed Plastics Starts with Material

When the greatest share of a product’s environmental impact comes from producing its feedstock, selecting the right material is critical. For 3D printing and manufacturing in plastic, biopolymer could be the first step toward a more sustainable model.

Read MoreNSL Powder360 Aids Powder Recycling for Reuse

RAPID 2021: NSL’s Powder360 provides powder characterization through alloy and process development, powder qualification and recycle for reuse.

Read MoreIs Recycled Metal Scrap the Future Feedstock of Choice for Metal 3D Printing?

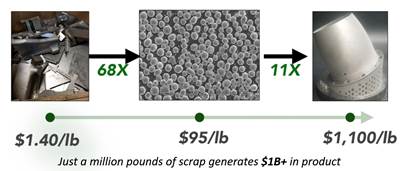

MolyWorks is future-proofing the circular economy for metals with small-footprint atomization technology that converts metal scrap into additive manufacturing powder on the spot. But that's not the end of the story.

Read MoreHow 3D Printing Enables Sustainability in a High-Turnover Consumer Market

Pengraff UK built its business initially providing mounting solutions for routers and telecommunications equipment, hardware with built-in obsolescence. 3D printing and sustainable materials enable the company to live its values while manufacturing products with a limited lifespan.

Read More