Retraction Footwear Is the Sustainable Manufacturing Business of the Future

Retraction Footwear offers a new way of buying flip-flops that are made to suit each customer. But the company also represents a new way of thinking about production, in a circular economy loop that encompasses material, design, manufacturing, product and end-of-life.

Retraction Footwear’s 3D printed flip flops are not just an example of mass customization; they represent a complete rethinking of the supply chain and a shift from the linear to the circular economy.

Wearing or using any product on a frequent basis is bound to expose some of its shortcomings, as was the case for Brett Casson and flip-flops, or thongs as they are more commonly called outside the U.S. “They’re pretty popular down here in Australia,” he says in a video call from a Melbourne suburb. “I’ve always worn thongs, and while I love them, there was always a bit of frustration with the standard design. I thought I could do better.”

That frustration centered on several characteristics common to thong footwear. Conventional flip-flops usually have a sole made of foam, which absorbs water and becomes slippery — and dangerous — when wet. These shoes rarely offer much in the way of arch support, making them less and less comfortable to wear over long periods of time. And, like other footwear, flip-flops come in only standard shoe sizes, often without even wide and narrow options.

Casson believed that these shoes could be made better, and not just improved in terms of material and fit. Actually made better— in other words, manufactured sustainably.

Casson believed that these shoes could be made better. And not just improved in terms of material and fit — actually made better, or in other words, manufactured in a more sustainable way that would reduce material and energy consumption, create less waste, and close the loop on the product lifecycle. In 2018, Casson quit his job to found Retraction Footwear, a shoe company focused on custom, sustainable flip-flops with a circular economy mindset.

3D Printing Advances Customization Toward “Infinite”

Casson has a mechanical engineering background but previously used this expertise in the construction industry. 3D printing has been his hobby for the past 5 years, however, and he has been able to apply what he’s learned about fused filament fabrication (FFF) printing to the Retraction Footwear business. The company just recently came to market in March 2020 with 3D printed thongs that are customizable in terms of their size, support and colors.

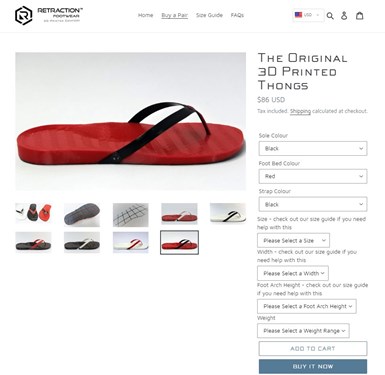

Retraction Footwear’s ordering interface allows the buyer to customize everything from shoe width to arch support.

Customers order online through the company’s website, and are able to select combinations of black, white and red shoe components (green and other colors will be available soon). A detailed sizing chart based on measurements in millimeters helps buyers choose the proper size and width for their shoes; support is determined based on weight and a choice of flat, regular or high arches.

Retraction Footwear is working on a smartphone app that would enable precise measurements of customers’ feet for “infinite customization,” Casson says. But even the drop-down menus that currently populate the ordering page represent a far greater variety of combinations than most shoe manufacturers can reasonably offer. Each and every pair can be different because 3D printing enables this kind of bespoke manufacturing, without tooling and within a lead time of only about a week from order to shipping. The flexibility and speed of the 3D printing process will be critical to enabling more complex and better designs for the shoes in the future.

3D Printing Footwear in a Circular Economy

While some startups see 3D printing as a ramp to higher production quantities through conventional methods, 3D printing will remain the right technology for Retraction Footwear’s custom shoes. No other manufacturing method would allow the company to make custom flip-flops so quickly. No other method would enable a bespoke product to be so affordable, both to purchase and to make. No other method could conserve material so well. No other method could be compressed into the footprint of a dozen tabletop machines. No other method could deliver on the promise of infinite and mass customization.

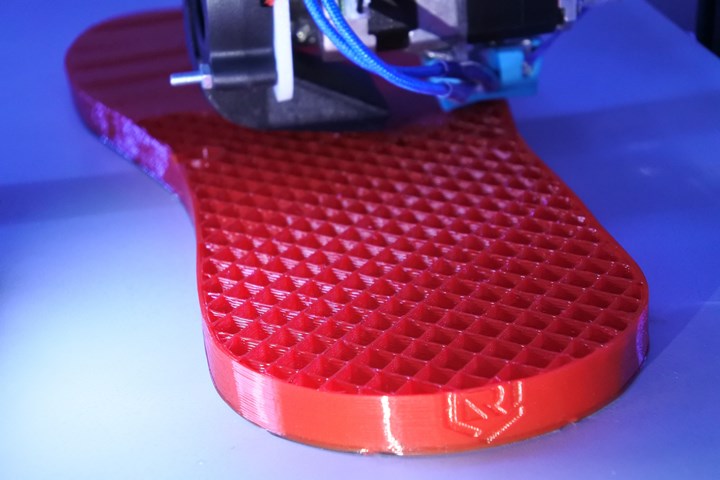

Rather than cutting foam down to size, Retraction Footwear 3D prints the entire shoe from just one type of material, NinjaFlex TPU from NinjaTek. A lattice infill imparts the same support and flexibility of foam in the sole, while other areas are printed as solid. The shoes are designed with Autodesk Fusion 360 and sliced with Simplify3D software.

But beyond an example of additive manufacturing for production, Retraction Footwear also represents a shift in thinking about the role of the manufacturer and the nature of production. Conventional footwear manufacturing is linear. Materials like foam are cut from larger pieces, leaving behind waste that must be discarded. The designs suited to the “average” person will turn out to be too large, too small, too firm or too soft for most wearers. Those standardized shoes are manufactured in large factories that consume high amounts of energy. The products are made in the standard 10 or so sizes that consumers are expected to buy, resulting in shortages in some cases and unused inventory in others. And when the shoes reach their end-of-life and the consumer no longer needs or wants them, they will more than likely wind up in a landfill.

Even the manufacturing process has been optimized for sustainability. Retraction Footwear’s Creality 3D printers have been heavily modified so that each one draws about the same amount of power as a standard lightbulb.

The model put forth by Retraction Footwear dismantles each of these linear steps. The company’s 3D printing process applies material only where it is needed, generating far less waste than conventional shoe manufacturing. The flip-flop design features an air cushioning system inside the sole which farther reduces the material used, and each design is right-sized to the customer. The thongs are manufactured with just 12 desktop 3D printers, each optimized to use only 50W of energy, or about as much as it takes to operate a standard light bulb. The product itself is made to order, preventing wasted inventory and providing the consumer with shoes that will last longer because they fit better. Retraction Footwear even has a vision for the end-of-life scenario — customers can return their unwanted thongs to the company, which is working to develop a recycling solution to turn old shoes into new filament. When it does, the circular economy loop will be complete for its product, enabling both sustainable production and consumption of these shoes.

Sustainable manufacturing can be supported and enabled by additive manufacturing.

It is easier for a startup like Retraction Footwear to think this way, to begin with this loop in mind. There are no incumbent processes to be retooled, no existing supply chains to be reworked, no loyal customers to reeducate. The same is true for additive manufacturing; it is easier to implement from a blank slate.

But like additive manufacturing, there are reasons for even established businesses to suffer the disruption of implementing sustainable manufacturing — and the pivot can be supported and enabled by AM at the same time. A sustainable manufacturing approach in conjunction with 3D printing can shorten supply chains, conserve resources and provide better products on faster timelines. Retraction Footwear and companies like it are proof that these concepts are not at odds with business or with manufacturing. Rather, they will be key to supporting a future of manufacturing that is better for all: producers, consumers and the planet.

Related Content

VulcanForms Is Forging a New Model for Large-Scale Production (and It's More Than 3D Printing)

The MIT spinout leverages proprietary high-power laser powder bed fusion alongside machining in the context of digitized, cost-effective and “maniacally focused” production.

Read More3D Printed Titanium Replaces Aluminum for Unmanned Aircraft Wing Splice: The Cool Parts Show #72

Rapid Plasma Deposition produces the near-net-shape preform for a newly designed wing splice for remotely piloted aircraft from General Atomics. The Cool Parts Show visits Norsk Titanium, where this part is made.

Read MoreHow Machining Makes AM Successful for Innovative 3D Manufacturing

Connections between metal 3D printing and CNC machining serve the Indiana manufacturer in many ways. One connection is customer conversations that resemble a machining job shop. Here is a look at a small company that has advanced quickly to become a thriving additive manufacturing part producer.

Read MoreMachine Tool Drawbar Made With Additive Manufacturing Saves DMG MORI 90% Lead Time and 67% CO2 Emission

A new production process for the multimetal drawbar replaces an outsourced plating step with directed energy deposition, performing this DED along with roughing, finishing and grinding on a single machine.

Read MoreRead Next

Voodoo Mfg. Microfactory Takes Desktop 3D Printers into Volume Production

Armed with a fleet of MakerBot 3D printers and its own proprietary software, Voodoo Mfg. is producing parts by the thousands from its small Brooklyn facility.

Read More3D Printing Helps Close the Loop for Armor’s Circular Economy

Manufacturing 3D printing filament was first a way for Armor to recycle its own reclaimed plastic waste. But now, this business unit is helping to close the loop on sustainability for plastic 3D printed products.

Read MoreGantri’s 3D Printed Luxury Lighting Brings Designers Closer to Consumers

The San Francisco startup is changing designer lighting with a designer-forward online marketplace and just-in-time delivery enabled by 3D printing.

Read More

.jpg;width=70;height=70;mode=crop)