Casting

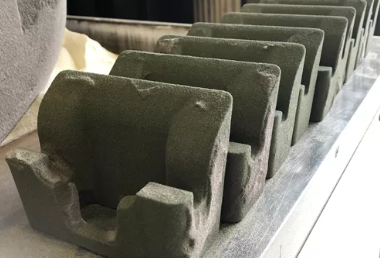

Optimized Castings, Fast Turnarounds with Sand 3D Printing

IMTS 2022: ExOne’s S-Max Flex pairs industrial robots with an end effector printhead design that deposits binder into a 1,900 × 1,000 × 1,000 mm (74 × 39 × 39") telescoping build box that grows as the parts are built layer by layer.

Read MoreCasting With Complexity: How Casting Plus 3D Printing Combine the Strengths of Both

Aristo Cast is advancing a mode of part production in which casting makes the part, but 3D printing enables the geometry.

WatchQualification Today, Better Aircraft Tomorrow — Eaton’s Additive Manufacturing Strategy

The case for additive has been made, Eaton says. Now, the company is taking on qualification costs so it can convert aircraft parts made through casting to AM. The investment today will speed qualification of the 3D printed parts of the future, allowing design engineers to fully explore additive’s freedoms.

Read MoreRobot Deposition Makes Giant Industrial Mixer Blade: The Cool Parts Show Bonus

Wire arc additive manufacturing produces a large component formerly made through casting, and allows for redesign of its internal cooling geometry.

WatchAM 101: Additive Manufacturing Materials

In processes like machining, the material is a known quantity. A part starts as a block of material, or perhaps a forging or casting. Its form changes in the machining process, but its inherent material properties are already set. In additive manufacturing, however, the material properties are being established alongside the geometry of the part.

Read MoreMassivit 10,000 Additive Tooling System for Composites Manufacturing

Rapid + TCT 2022: The system utilizes the the company’s Cast In Motion technology, which is said to enable direct printing of complex molds using high-performance casting materials.

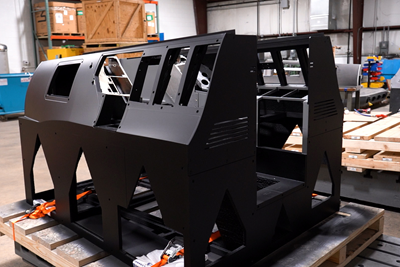

Read MoreDesktop Metal’s Robotic Additive Manufacturing System for Sand Printing

The ExOne S-Max Flex system use single-pass jetting technology to deliver 3D printing at high speeds for low-cost parts.

Read MoreABB Selects Additive Industries’ MetalFAB1 for On-Demand Digital Spare Parts Production

This Turbocharger manufacturer replaces casting with industrial 3D printing, reducing its spare parts manufacturing lead times from nine weeks to one as well as significantly reducing its spare parts inventory levels.

Read MoreUsing Large-Format Additive Manufacturing for Serial Production

First tools, then production parts. This pattern with industrial 3D printing at small and mid sizes has now come to the biggest additive machines as well.

Read MoreBigRep Pro Large-Format Printer Designed for All Stages of Manufacturing

The company says the printer is versatile to enable the production of full-scale, large parts, including functional prototypes, factory tooling, patterns, molds and end-use parts.

Read More