Casting

Hoosier Pattern's 3D-Printed Sand Enables Complex Castings

Rapid 2018: Hoosier Pattern’s 3D-printed sand helps foundries produce complex castings and enables low-volume production and prototyping in a range of industries.

Read MoreThermwood 3D Prints Large Boat Hull Pattern

Thermwood’s large-scale additive manufacturing (LSAM) technology enabled the fabrication of a 3,000-lb plug for a boat hull mold. The project illustrates how 3D printing could help reduce fabrication costs for marine composites.

Read MoreFoundry Says Robotic Sand Printing a “Game Changer” for Metal Casting

The Hazleton Casting Company augments its traditional foundry operations with additive manufacturing. A new sand 3D printing system is expanding options for the foundry’s customers in areas including legacy tooling, product development and design complexity.

Read MoreHow Forecast 3D Is Taking 3D Printing into Mass Production

Forecast 3D got its start building silicone molds from 3D-printed master patterns. Now, through the use of Multi Jet Fusion, the company sees a future in manufacturing large quantities of 3D-printed parts.

Read MoreAerospace Project Pairs 3D Printing with Investment Casting

A research project conducted by Autodesk reduced the weight of an airplane seat frame using 3D-printed patterns and investment casting in magnesium.

Read MoreCasting a New Light on Manufacturing

3D printing brings new possibilities to a functional part we might have never thought of as a functional part: the rigid cast used to heal bones.

WatchCase Studies of Multi-Material Manufacturing

Tools for injection molding, die casting and powder compaction all illustrate the potential to achieve greater part performance and manufacturing efficiency by blending workpiece materials through AM.

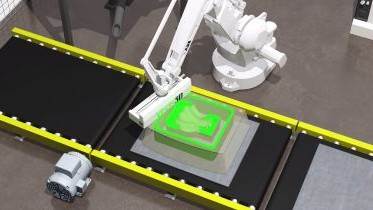

Read MoreVideo: Additive Manufacturing Robot for Foundry Molds

In addition to making either metal or plastic parts, one other production application of additive manufacturing is building in sand to create molds for casting without any need for a pattern.

WatchPros and Cons of Making Foundry Patterns Via 3D Printing

A new method of pattern making brings various advantages, not the least of which is expanded design freedom. But 3D printing of patterns is not without trade-offs.

WatchSand Printing’s Side Benefit

A pattern maker is now able to skip the pattern by printing foundry mold components directly in sand. This figurine is a byproduct of the way the company batches the sand-printing jobs for greater efficiency

Read More