I posted a recent commentary about the continued advance of hybrid machine tools — machines that add 3D printing to CNC machining and can perform both in the same cycle. An early innovator in this area is Jason Jones. He is a co-founder of Hybrid Manufacturing Technologies (HMT), which provides tool-changeable metal deposition systems for CNC machine tools. At a basic level, the potential value of being able to 3D print and machine in a single setup is not hard to appreciate, but there is more to see about the specific role and promise of these machines. A recent conversation with Dr. Jones about the state and application of hybrid machines brought out a number of points contributing to a better understanding of hybrid, including the following:

1. Hybrid is the AM option used in contexts that may not involve design.

Hybrid machine tools are used for repair, cladding, adding features to parts, and printing entire parts. And part of what is significant is that there is a range of different levels of design input needed across that list. For repairs, the design already exists — the goal is to return a tool or part to that design. But for complete parts, a design is needed — and one that plays to the strengths of additive manufacturing. The other applications fall somewhere in between.

“The term we use is ‘design authority,’” Jones says. “Machine shops often don’t have this,” he notes, even though machine shops are natural adopters because hybrid gives them a straightforward way to add metal additive capability. In machining facilities, because they tend not to control design, repair work is often a bread-and-butter hybrid application.

2. Heat treating need not be a barrier to hybrid application.

Many parts need heat treatment between 3D printing and finish machining. Doesn’t the need for this step rule out performing both operations in a single hybrid cycle? It does not have to, Jones notes, because putting a complete part into a furnace is not the only way to perform heat treating.

“There are many processes in which we globally heat treat the entire part because that is what we have been doing for years,” he says. But an alternative, local heat treating of just the critical region of the part needing this treatment, is a step that can be incorporated into a hybrid cycle.

There is another consideration, he notes: Heat treating in many cases is a concession to the assumption that only one metal can be used to make the solid form. A multimetal solution often gives higher performance than using one material alone, even after heat treating, he says. The next point relates to this.

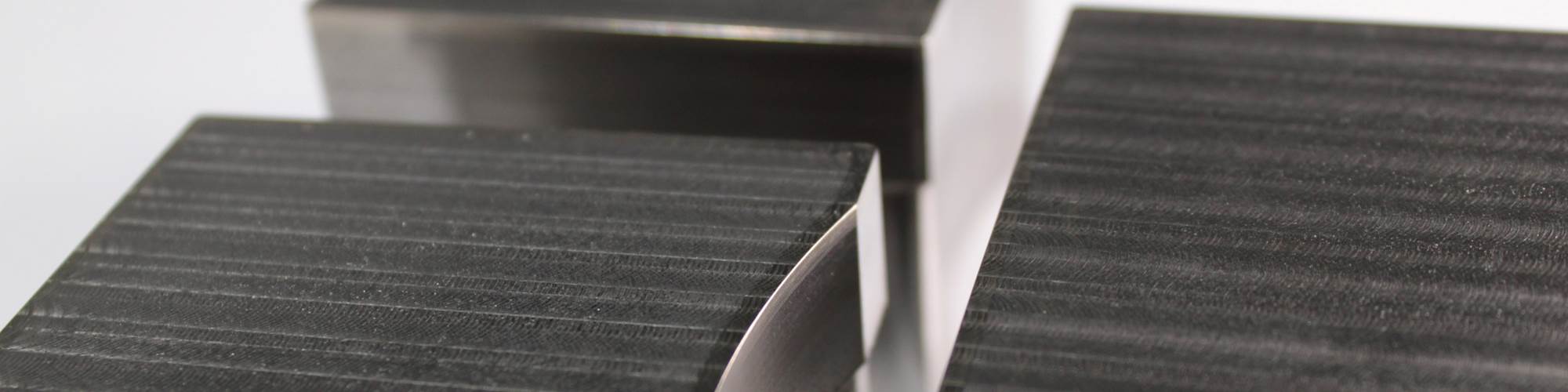

The life of this tooling insert is largely determined by wear at the edges of the upper surface seen here. Hybrid can be used to bring wear resistance to this region, as an alternative to making the entire part from an expensive wear-resistant material. For this part, edge life is dramatically extended with a 3D printed metal matrix composite combining metal and ceramic. The bulk of the insert is then made of less expensive cast iron. (All photos in this article are courtesy of Hybrid Manufacturing Technologies.)

3. Cladding via hybrid provides a multimaterial option for hard or otherwise high-performance components and tooling.

Many applications of hybrid involve seemingly straightforward additive operations — cladding, for example. But then again, cladding is more than cladding if it can be combined with precision machining in a single step. HMT has been involved in projects demonstrating how die making can be simplified by cladding the hard surface onto a tool body that is otherwise made of a softer metal that is cheaper and easier to work with. (On other types of parts, the same technique provides a way to efficiently realize oxidation or corrosion resistance.)

“We have seen that a single layer of deposition, a few millimeters in some cases but as small as 0.1 mm in others, can deliver equivalent hardness to a tool made globally of the same hard material,” he says.

4. Hybrid captures more of the AM process than other 3D printing platforms.

Additive manufacturing is not just 3D printing. In Jones’ alliterative terms, AM has to include “forming, fusing, finishing and finalizing.” Respectively, that means the process has to involve material layering; consolidating the layers; machining; and inspection and validation.

The hybrid platform allows for 3D printing, machining and measurement in a single cycle on a CNC machine tool. HMT developed the deposition head at left and the inspection head at right.

“In AM, all four of these need to be there. But the dialog around 3D printing tends to focus on just forming and fusing. The postprocessing often gets swept under the rug,” he says. A strength of hybrid is that it offers an additive manufacturing platform combining all these considerations. Machining is as much of the process as 3D printing, and the unification into one setup speaks to quality control. Incorporating an inspection head within the same hybrid platform can complete this sequence.

5. Parts with embedded sensing are the coming application for hybrid machines.

The successes of hybrid applications are following a trajectory advancing from prototypes to parts to smart products. Prototype applications are well established. “Parts are where we are now,” Jones says. Next step: Using hybrid to create products that can self-regulate or self-monitor through embedded sensing.

Jones notes that hybrid platforms are naturally equipped to deliver this. The operations in a hybrid system do not have to stop at material deposition and machining. The capacity to automatically install embedded functionality during the cycle is another feature of hybrid systems that will be natural to develop as these applications advance.

Related Content

Video: For 3D Printed Aircraft Structure, Machining Aids Fatigue Strength

Machining is a valuable complement to directed energy deposition, says Big Metal Additive. Topology-optimized aircraft parts illustrate the improvement in part performance from machining as the part is being built.

Read MoreHow Machining Makes AM Successful for Innovative 3D Manufacturing

Connections between metal 3D printing and CNC machining serve the Indiana manufacturer in many ways. One connection is customer conversations that resemble a machining job shop. Here is a look at a small company that has advanced quickly to become a thriving additive manufacturing part producer.

Read MoreHow 3D Printing Aids Sustainability for Semiconductor Equipment: The Cool Parts Show Bonus

Hittech worked with its customer to replace fully machined semiconductor trays with trays made via DED by Norsk Titanium. The result is dramatic savings in tool consumption and material waste.

Read MoreZeda AM Production Plant in Ohio Now Open — Thoughts on the New Facility

73,000-square-foot metal powder bed fusion plant includes extensive machining capability plus separate operational models for serving medical versus other businesses.

Read MoreRead Next

Hybrid Additive Manufacturing Machine Tools Continue to Make Gains (Includes Video)

The hybrid machine tool is an idea that continues to advance. Two important developments of recent years expand the possibilities for this platform.

Read MoreCrushable Lattices: The Lightweight Structures That Will Protect an Interplanetary Payload

NASA uses laser powder bed fusion plus chemical etching to create the lattice forms engineered to keep Mars rocks safe during a crash landing on Earth.

Read MoreAlquist 3D Looks Toward a Carbon-Sequestering Future with 3D Printed Infrastructure

The Colorado startup aims to reduce the carbon footprint of new buildings, homes and city infrastructure with robotic 3D printing and a specialized geopolymer material.

Read More