Omni-Pac, HP Join Forces to Transform Molded Fiber Production, Reduce CO2 Emissions

The companies say this pioneering collaboration will drive digital transformation and sustainability in the packaging industry.

Omni-Pac Group, a molded fiber packaging provider, has partnered with HP to digitize and transform the way molded fiber is produced at an industrial level. This collaboration is helping Omni-Pac reduce CO2 emissions and replace single-use plastics with more sustainable packaging solutions. By working together, both companies are aiming to drive innovation and sustainability in the molded fiber industry.

Pablo Libreros, CEO of Omni-Pac Group, expressed his excitement, emphasizing the company’s leading role in driving innovation and sustainability within the industry through its collaboration with HP. “Our collaboration with HP allows us to revolutionize the production of molded fiber at an industrial scale, transforming the development, launch and production of molded fiber applications,” Libreros says. “This not only reduces environmental impact but also pioneers sustainable packaging solutions.”

Libreros also highlighted the significant benefits of the collaboration. “Enabling us to achieve over 500 tons per machine per year through digitalization, the level of CO2 savings will continue to improve as our collaboration with HP progresses,” he adds.

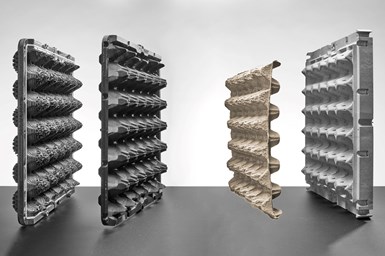

HP’s Molded Fiber Tooling Solution provides a customized digital solution for companies like Omni-Pac, enabling them to achieve unprecedented levels of efficiency and sustainability. The adoption of HP’s technology empowers Omni-Pac to deliver innovative products that meet the evolving needs of consumers and businesses. The solution includes the HP Molded Fiber Advanced Tooling technology, which optimizes manufacturing processes, delivering high-quality products with enhanced performance through Computational Fluid Dynamics (CFD) grammage control and customized features such as logos and textures.

Additionally, it significantly enhances Molded Fiber packaging sustainability by reducing the carbon footprint during tooling and part production, resulting in lighter parts with equal or better performance.

Mariona Company, global head of fiber-based sustainable packaging at HP, notes the significance of the collaboration. “HP's Molded Fiber Tooling Solution technology is empowering companies like Omni-Pac to deliver efficiencies, enable new products, and reduce CO2 emissions,” Company says. “By working together, Omni-Pac and HP are at the forefront of driving innovation and sustainability in the molded fiber industry.”

HP says its ambition is to be a lighthouse brand for purpose. By 2030, the company intends to become the world’s most sustainable and just technology company. With a shared vision and common goals, Omni-Pac and HP are united in their commitment to creating a better future. This collaboration is said to serve as a testament to the power of innovation, driving the industry toward a more sustainable and environmentally conscious approach to packaging production.

- Read about growing additive manufacturing adoption with HP aiming for the C-Suite. 3D printing has been largely the purview of service bureaus and technical specialists, but HP sees a future where it is increasingly the concern of OEM executives — and the company is taking steps to reach them.

- Here’s more news from HP as it expands automation solutions for advancing 3D printing path to production. HP’s Jet Fusion automation solutions are designed to simplify workflows and reduce costs for high-volume 3D production. The company has also expanded its materials, HP Digital Production Suite and HP Digital Production Services for polymer and metal customers.

Related Content

Next-Gen Horse Trailers to Be Built With Robotic 3D Printing

Double D Trailers is currently developing a prototype horse trailer that will be made with large-format additive manufacturing. The technology brings potential benefits for labor, weight and design features to this subset of recreational vehicles.

Read MoreGE Additive Helps Build Large Metal 3D Printed Aerospace Part

The research is part of an initiative to develop more fuel-efficient air transport technologies as well as a strong, globally competitive aeronautical industry supply chain in Europe.

Read More3D Printing Brings Sustainability, Accessibility to Glass Manufacturing

Australian startup Maple Glass Printing has developed a process for extruding glass into artwork, lab implements and architectural elements. Along the way, the company has also found more efficient ways of recycling this material.

Read MoreBMW Expands Use of Additive Manufacturing to Foster Production Innovations

The BMW Group is manufacturing many work aids and tools for its own production system using various 3D printing processes, with items such as tailor-made orthoses for employees, teaching and production aids, and large, weight-optimized robot grippers, which are used for such things as carbon fiber-reinforced polymer roofs and entire floor assemblies.

Read MoreRead Next

Alquist 3D Looks Toward a Carbon-Sequestering Future with 3D Printed Infrastructure

The Colorado startup aims to reduce the carbon footprint of new buildings, homes and city infrastructure with robotic 3D printing and a specialized geopolymer material.

Read MoreCrushable Lattices: The Lightweight Structures That Will Protect an Interplanetary Payload

NASA uses laser powder bed fusion plus chemical etching to create the lattice forms engineered to keep Mars rocks safe during a crash landing on Earth.

Read MorePostprocessing Steps and Costs for Metal 3D Printing

When your metal part is done 3D printing, you just pull it out of the machine and start using it, right? Not exactly.

Read More