Additive manufacturing with materials like polymers, metals and ceramics can be done sustainably — by choosing recyclable materials or those based on renewable resources. But AM thus far has mostly overlooked a material that is, at least in theory, “infinitely recyclable”: glass.

Victoria, Australia, startup Maple Glass Printing was founded to develop a means of more easily manufacturing parts and structures from glass. But the material is expensive, and the founders quickly found themselves reusing scraps of glass to make new filament. Sustainability has been a tenet of the company ever since, along with its mission to lower the barriers to entry in glass manufacturing.

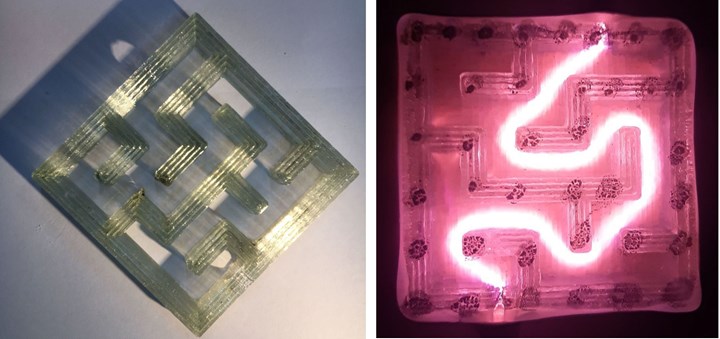

The initial concept for Maple Glass Printing was to make it easier and more accessible to produce glass objects without the use of molds or need for great skill. The company has found it possible to produce unusual and complex designs like this through its extrusion-based process; to join 3D printed glass with conventionally blown or shaped glass; and to manufacture glass items using fully recycled material. Photo Credit: Maple Glass Printing | Design: Brandyn Callahan and Phirak Suon

Lowering the Barriers to Glass Manufacturing

Maple Glass Printing was co-founded in 2017 by two materials engineers, Nick Birbilis and Darren Feenstra, who met at Monash University. (Feenstra hails from Canada — hence the use of “maple” in the company’s name.)

The idea behind the startup and its technology was initially to speed the process for manufacturing objects out of glass. Commercially, glass items are made by casting the molten material into molds, which makes it prone to many of the same tooling challenges and geometry restrictions as other processes based on tooling. Glass blowing offers another production method, but is time-consuming, size limited and requires great skill.

Conventional glass manufacturing is constrained by the necessity for tooling and skilled labor; 3D printing opens the door to greater accessibility and more complex designs like these display pieces made from recycled glass, developed by Foster + Partners in collaboration with Maple Glass Printing. Photo Credit: Maple Glass Printing

“The 3D printing process allows for such a different type of manufacturing,” says Tony Koutsonikolas, research and development mechanical engineer. The company sees their extrusion-style technology as a means to achieve many of the same benefits that FFF and DED have brought to polymers and metals, respectively — in terms of geometric complexity, avoidance of tooling, and the flexibility to iterate designs more rapidly.

It took several years to develop a working glass 3D printer and produce the first test pieces, but these successes allowed the startup to “graduate” from a Monash lab to its own space in 2020. Now in 2023, the company is introducing its first commercial machines for glass 3D printing, the Maple 2 and Maple 3.

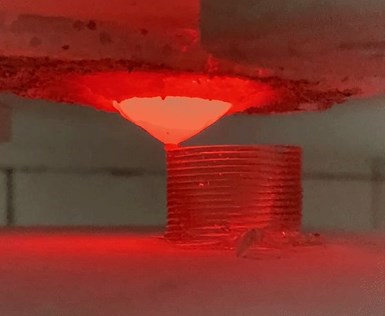

How to 3D Print with Glass

The Maple 3 is the company’s latest commercial printer, featuring a nozzle that heats to 1,000ºC and a traveling build plate. Future iterations of the machine will reverse this to allow for a larger print area inside the same footprint. Photo Credit: Maple Glass Printing

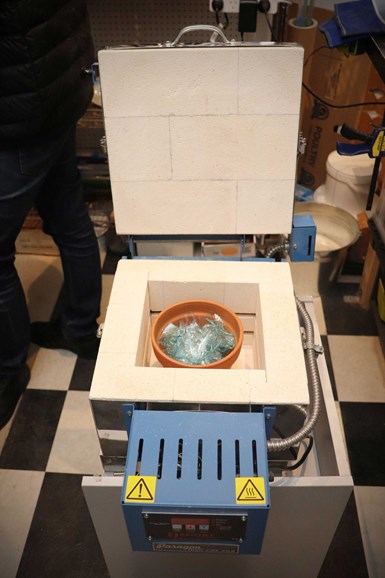

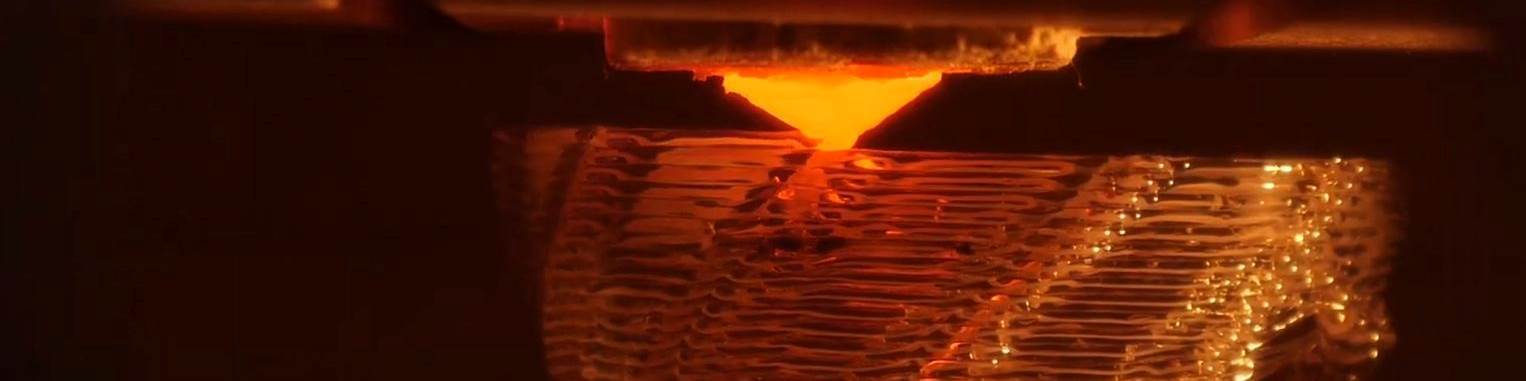

Maple Glass Printing’s current platforms use glass rods known as glass “cane” as the feedstock. A stationary nozzle inside the Maple 2 and Maple 3 printers heats the material to 1,000°C, then deposits the molten glass onto a moving build platform. The entire process takes place in a build chamber that is effectively a kiln — and which, in early iterations, literally was a repurposed one.

Despite the high temperatures needed to melt glass, only a small amount of the material needs to be heated at once for extrusion. According to the company, the Maple 3 uses less electricity than a hairdryer. Photo Credit: Maple Glass Printing

(In future versions of this machine, Koutsonikolas says, the motion will be reversed with the nozzle moving rather than the plate; the build chamber will stay the same, but the envelope will grow with the nozzle able to access more of the space inside the kiln.)

Even though glass printing requires significantly elevated temperatures compared to other materials, it is actually a fairly energy efficient process. According to advanced manufacturing engineer Dylan Vlahopoulos, the machine uses five times less power than a hair dryer.

“Only a very small area needs to be heated at once,” he says, and each layer of glass is only hot for a short amount of time.

The rapid solidifcation of the glass material following extrusion makes it possible to reliably print bridges and overhangs as demonstrated with this piece. Photo Credit: Maple Glass Printing | Design: Noah Shipley

The limited use of heat in the process also brings advantages to the final glass print. Geometric features like overhangs and bridges are possible because of how quickly the material cools and sets into place. Localized heating and cooling also prevents build up of stresses, which can happen in glass blowing and casting where the material is allowed to cool all at once. Effectively, the glass is printed and annealed at the same time; the controlled, localized cooling of the material avoids stresses that can happen when cooling blown or commercially manufactured glass parts that are formed all at once, Vlahopolous says.

Early applications for the platform have mostly centered on artistic projects and demonstration pieces, as well as some lab implements produced for researchers studying neon and fiber optics. And while the glass 3D printer can print parts for use as-is, the company has also experimented with combining printed glass with more conventional glass-making techniques. It is possible, for example, to 3D print essentially a preform structure which a skilled glass artisan can then modify or even augment with manually shaped or blown elements.

One early collaboration involved producing this glass maze for a researcher studying the behavior of neon gas. The second image shows how the neon found the shortest route through the maze. Photo Credit: Mark Title

A Circular Economy for Glass

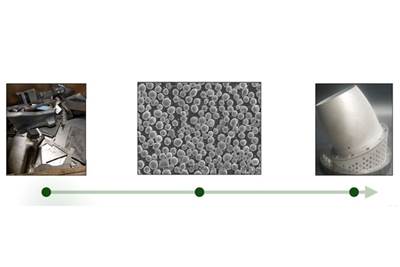

Glass cane is traditionally manufactured by hand, in a process that produces variation in the finished product. To reduce the cost of its feedstock, Maple Glass Printing has developed a machine specifically for pulling straight, consistent glass cane like this from recycled material. Photo Credit: Maple Glass Printing

Along the way to developing the 3D printing technology, Maple Glass Printing has discovered ways of closing the loop for this material. The expense of the glass cane feedstock as described above led the co-founders to begin recycling scrap to produce test prints early on. In order to re-use that spent glass, they had to come up with a way of turning it back into glass cane.

Today most glass cane is produced manually, by a human technician literally stretching molten glass into fine strands. The process is tedious and even the most practiced glass puller will produce cane that varies in straightness and diameter across its length. The labor-intensive process coupled with the fact that glass cane is made from new materials combines to make this feedstock quite expensive.

The Vitri-Glass automates the task of producing glass cane. Glass scraps are melted in the crucible at the top, then extruded and pulled to the correct size. Photo Credit: Maple Glass Printing

Maple Glass Printing either had to become good at drawing glass into cane itself, or come up with another solution. The company ultimately developed another machine alongside the 3D printer platform: the Vitri-Glass.

This piece of equipment features a crucible on the top where glass pieces can be loaded and melted. The machine then extrudes the cane and a technician guides it into an automated pulling system. The speed of the pull can be controlled to produce cane that is thicker or thinner depending on the application. While the process still requires human attention, it results in much more consistent glass cane with less difficulty — and provides an easy way for a glass 3D printing user to recycle prototypes, scraps or spent products into feedstock.

“We don’t live in a perfect world,” Vlahapolous says, “but in theory, glass is infinitely recyclable.”

Glass scraps of different colors must be processed separately (coloring agents can influence properties such as stiffness), and there is a risk of crystallization that could make the recycled cane unusable. However, the benefits from reusing glass far outweigh the risks, and Maple Glass Printing is now leaning into the recyclability of the material as a critical advantage of its technology.

3D Printing Glass Beyond the Kiln

Maple Glass Printing is now experimenting with robotic 3D printing to produce larger and larger glass structures, often in combination with other printing techniques. This demo piece combines glass with 3D printed PETG; a design like this could be expanded to serve as a building facade, room divider or other architectural element. Photo Credit: Zechen Huang and Shuming Zhou (Tectonic Formation Lab, RMIT University)

Finding efficient means of recycling glass via the 3D printing process has implications not only for glass printing users who want to reduce their waste, but also for reclaiming glass that is already in the world. Maple Glass Printing sees great potential in recapturing glass that makes up windows and facades, and these architectural applications could become more important for the company in the near future.

While the Maple 2 and 3 machines are confined to the build envelope of the kilns in which they operate, the next generation of glass 3D printers that the company is developing will comprise a printhead on a robot arm to build much larger structures in the open. The company’s learning about how to print glass inside a kiln as well as how to extrude it into a room temperature environment with the Vitri-Glass process are both informing this work. Because only a small amount of glass is molten at a time and rapidly cools, the impacts on material properties should be minimal for this open air, large-format printing.

One future promise of this LFAM work will be integrating the printed glass with other architectural elements, such as metal frames that could be produced through a processes such as wire arc additive manufacturing (WAAM). While the printed glass will always appear layered, there are plenty of applications where windows don’t need to be perfectly clear, and the bead size can be adjusted to achieve the desired diffusion or other effect.

This photo shows a demonstration of robotic 3D printing in polymer; Maple Glass Printing says that its large-scale process in glass will look similar. The company is collaborating on this work with the Royal Melbourne Institute of Technology (RMIT). Photo Credit: Tectonic Formation Lab

The large-format solution is still in work, and in the meantime the company is focused on identifying and developing applications for its smaller-sized commercial machines. It’s not yet clear where all the possible opportunities for such a solution will be found, but the company is confident its technology can make a difference not only in how glass is manufactured, but also how it is recaptured and recycled.

“How we treat glass in the future could change quite a lot,” Koutsonikolas says.

Related Content

Sustainable Furniture Company Model No. Maintains Product Focus with Switch from DIY to Industrial 3D Printers

The startup founded in 2018 has matured in its product offerings as well as its manufacturing equipment, moving from homegrown 3D printers to industrial large-format machines.

Read MoreHow 3D Printing Aids Sustainability for Semiconductor Equipment: The Cool Parts Show Bonus

Hittech worked with its customer to replace fully machined semiconductor trays with trays made via DED by Norsk Titanium. The result is dramatic savings in tool consumption and material waste.

Read MoreConcept Sneaker Boasts One-Piece 3D Printed TPU Construction

The Reebok x Botter Concept Sneaker Engineered by HP premiered at Paris Fashion Week, hinting at manufacturing possibilities for the future of footwear.

Read MoreNext-Gen Horse Trailers to Be Built With Robotic 3D Printing

Double D Trailers is currently developing a prototype horse trailer that will be made with large-format additive manufacturing. The technology brings potential benefits for labor, weight and design features to this subset of recreational vehicles.

Read MoreRead Next

Why “Recycled” Doesn’t Mean Inferior for 3D Printing Filament

GreenGate3D’s PET-G filament is made from recycled plastic, but that doesn’t diminish its quality. How a recycler found a new business opportunity in 3D printing, and how this success might point the way to a more effective recycling ecosystem.

Read MoreSustainability in Additive Manufacturing Is a Moving Target: AM Radio #37

Assessing 3D printing as a sustainable manufacturing method is a complex problem. Dr. Tim Simpson and Stephanie Hendrixson discuss current research and future opportunities on AM Radio.

Read MoreFor Sustainable 3D Printed Architecture Think Renewable, Not Permanent

The design choices of today won’t be the trends of tomorrow. Aectual chooses to embrace changing tastes by making it easy to procure and recycle 3D printed architectural elements.

Read More

.jpg;width=70;height=70;mode=crop)