Markforged Acquires Teton Simulation

Integration of Teton’s cloud native simulation software into Markforged’s Digital Forge platform will enable manufacturers to validate advanced composite parts for demanding production applications.

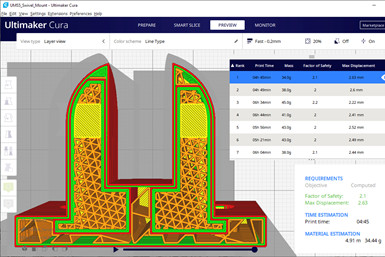

Teton Simulation’s SmartSlice software. Photo Credit: Teton Simulation

Markforged, creator of The Digital Forge — an integrated metal and carbon fiber additive manufacturing (AM) platform — has acquired Teton Simulation Software, whose SmartSlice technology automates validation and optimizes part performance for AM applications.

Markforged says it will integrate Teton’s technology with its Eiger 3D printing software solution as a subscription add-on that will offer all manufacturing customers (including small- and medium-sized businesses) a streamlined workflow spanning part design, testing, optimization, validation and printing at the point of need, all on a single, cloud-based platform.

The acquisition is said to enhance Markforged’s offering in distributed manufacturing by extending its end-to-end platform with fast, automated validation of demanding end-use parts and applications.

The company says this acquisition adds strategic functionality to the Digital Forge to give Markforged’s users the confidence that printed parts will perform as intended, enabling them to replace even more end-use metal parts with validated continuous fiber reinforcement (CFR). This addition to Markforged’s software offerings is said to help customers take the guesswork out of configuring slicing parameters for end-use requirements, knowing they can estimate part performance without a wasteful, slow process of physical testing.

Teton says its software technology is built to enable rapid validation and optimization of 3D print parameters to ensure that performance and manufacturing requirements are realized. The SmartSlice product integrates with slicer programs and is said to replace the typical print-break-repeat prototyping cycle to speed up development and reduce the time and cost of production-quality parts. Teton’s team will join Markforged’s software organization to help expand the number of industrial problems that The Digital Forge solves.

“The acquisition of Teton Simulation advances our industry leadership in using software to increase process automation and offers our customers an easy way to validate their parts on the same platform they use to print them,” says Shai Terem, Markforged president and CEO. “Adding this functionality enables our customers to utilize The Digital Forge deeper into their manufacturing operations.”

Related Content

-

User-Friendly Mass Spectrometry Tool to Enable AM

The Massbox is a technology designed to simplify mass spectrometry by bypassing the need to send samples to the lab for characterization and testing purposes. Exum Instruments’ debut tool is suitable for AM as it can assist with quality assurance, material characterization and failure analysis.

-

Implicit Modeling for Additive Manufacturing

Some software tools now use this modeling strategy as opposed to explicit methods of representing geometry. Here’s how it works, and why it matters for additive manufacturing.

-

Overcoming the Bottleneck to Customized Manufacturing: Quoting

Spokbee’s software-as-a-service platform is shaving months off of the quoting and pricing process for 3D printed and other types of configurable products.