Material properties and chemical characterization prove challenging to measure even with a degree in chemistry, as the traditional processes and available tools are inaccessible and time consuming.

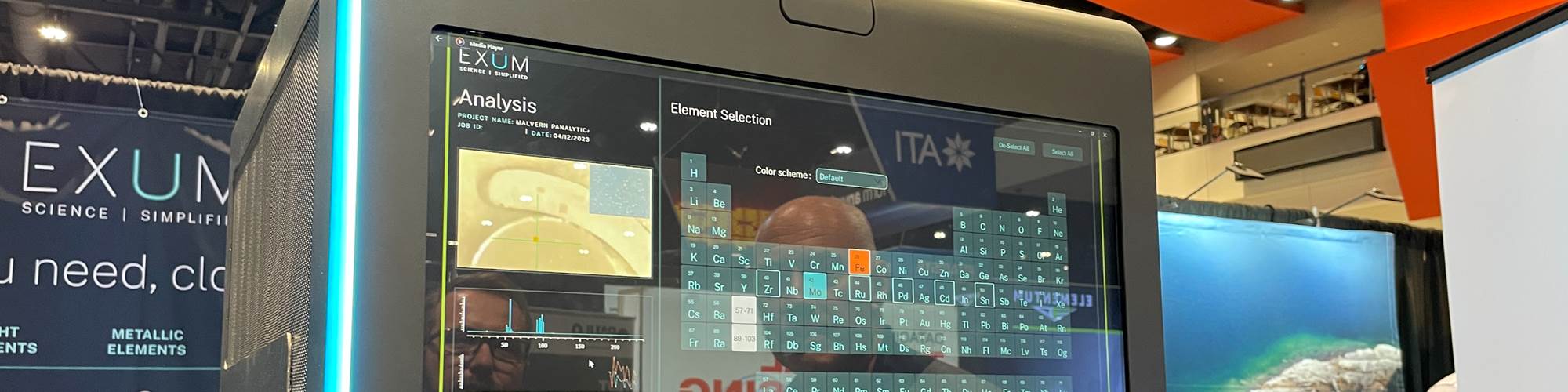

While attending RAPID + TCT 2023 in Chicago, I stopped by Exum Instruments’ (Exum) booth to see its debut mass spectrometry tool, the Massbox. The accessible technology functions as an easy-to-use desktop device for material testing and measurement purposes to circumvent sending samples through a laboratory.

The Massbox enables quick and accurate chemical characterization, outside the traditional laboratory environment. The accessible tool easily fits atop a desk, as seen in the above image.

In additive manufacturing (AM), testing a metal’s chemical composition requires at least three analytical techniques, plus professional expertise and considerable lab time to ascertain results. While widely applicable, the Massbox is a particularly practical instrument for AM as it saves precious time in material characterization, thus shortening production cycles to ultimately reduce lead times.

This new instrument measures the metallic, trace and light elements of a sample in minutes and displays the results on an easy-to-use touchscreen. The Massbox’s smallness (sized to fit easily on a desktop) makes it possible to conduct this measurement outside of a lab environment. To operate, the Massbox only requires a standard power outlet with no additional gas bottles or large peripheral equipment like those used by traditional spectroscopy tools.

With this device, a chemistry background is no longer mandatory to prepare a sample for testing, complete its analysis or create chemical maps derived from results.

How Desktop Mass Spectrometry Operates

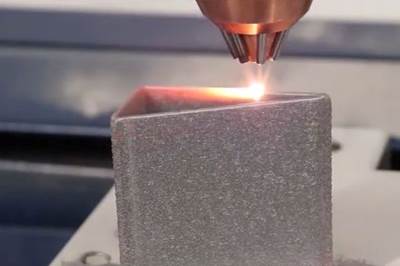

The Massbox mass spectrometer combines Exum’s patented, dual-laser ionization source, Laser Ablation Laser Ionization (or LALI) with the Time of Flight (TOF) mass spectrometry. This technology enables the Massbox to test for a variety of elements and makes it possible to detect the presence of an unwanted substance in a powder or printed sample.

The Massbox combines Exum’s patented, dual-laser ionization source, Laser Ablation Laser Ionization (or LALI) with the Time of Flight (TOF) mass spectrometry. The laser ablation process is depicted in the image above.

At a simplified level, the first laser ablates, or releases, a small amount of material from the sample’s surface. Then a second laser creates ions from the suspended particles released by the first laser. Ions are required by every mass spectrometry technique to identify the elements in the sample.

This process offers a non-destructive form of material testing, meaning a reduction in otherwise unnecessary sample waste and cleanup.

The Process: Powder to Part

The Massbox can be applied at multiple stages in the additive workflow, from start (testing of pressed powders for material choice) to finish (testing end-product sample), making it an optimal tool for characterizing feedstock and for build assurance.

When it comes to feedstock quality control, the Massbox is able to verify the chemical composition of recycled powder to ensure it still meets AM specifications. The quick chemical analysis solution means that powder after each build cycle can be checked for reuse, ultimately reducing costs associated with disposing of powder prematurely.

For material characterization, feedstock samples in the form of pressed powders, roughly the size of a coin, can be placed inside the Massbox for testing. The high-throughput instrument can test up to 16 of these samples at once.

The Massbox can test an array of samples, from materials in the form of pressed powder (as depicted above) to smaller test parts.

In terms of quality assurance, the Massbox is able to conduct failure analysis of test samples, as well as small final parts. The Massbox enables mapping of an area measuring 83 by 83 by 29 mm, meaning end-use parts must not exceed the measurement field itself.

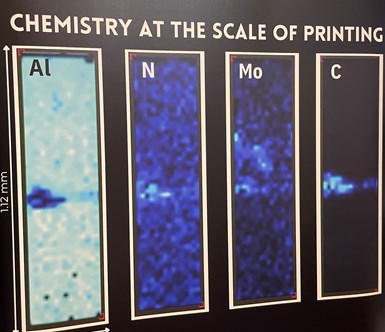

Once inside, the device enables trace-level detection (where small quantities of chemical elements in a sample are determined) for nearly the entire periodic table. The Massbox provides chemical mapping for the measurement of spatial heterogeneity (or the uneven distribution of different concentrations within a defined area) as well as depth profiling of the given sample.

In other words, every nook and cranny of the sample can be evaluated to ensure its chemical makeup.

An Accessible Measurement Tool

Size-wise, the Massbox itself measures 30 by 24 by 27 inches. Thus, the tool can easily fit in a variety of environments (for instance, an already packed additive facility). A portable device, the Massbox simply plugs in and is ready for immediate use.

The intuitive interface takes only a few hours of minimal training to learn the functions before use. From here, it’s only a matter of minutes before obtaining accurate, useful and detailed analytical results regarding the material or sample of choice.

Users can view results on the touchscreen via elemental mapping or heat mapping. This hands-on approach allows the user to zoom in for a closer look at how different elements are interacting in the given sample.

The Massbox is complete with a cloud-based storage system for careful data storing and processing that is consistent with other additive technologies.

According to Exum, the Massbox is also easy to clean and calibrate for optimal use, making it an effective tool for improving time management while promoting user accessibility.

Mass Spectrometry Outside the Lab

In additive, where reducing lead times is a key factor, Exum sees the Massbox as a means to reduce the need for the middleman (or in this case, the lab). While the Massbox cannot replace all laboratory testing, users of this device can cut down production time by reducing the time needed to travel to the laboratory, test the material or sample in question, and wait for results.

Along with extricating mass spectrometry from its traditional laboratory environment for measurement and characterization, the Massbox also potentially minimizes the risk of error. While additive is laden with automation and digitalization, material analysis has remained very manual.

With a compact, easy-to-use mass spectrometry solution like this, additive manufacturers can implement material analysis more easily and more frequently, in a more autonomous fashion.

Related Content

Hybrid Additive Manufacturing Improves Debarking Knife Tip Strength and Production Efficiency

Nicholson Manufacturing chose the Mastercam APlus specialized add-on to unlock hybrid manufacturing for making its debarker knife tips, enabling it to add durable layers to the wear surfaces of the tips to make them more resilient while also making the production process more efficient.

Read MoreOvercoming the Bottleneck to Customized Manufacturing: Quoting

Spokbee’s software-as-a-service platform is shaving months off of the quoting and pricing process for 3D printed and other types of configurable products.

Read MoreDecentralized Manufacturing Network Aims to Make 3D Printers a Shared Global Resource

The 3DOS additive manufacturing network will let OEMs and creators take advantage of open 3D printer capacity anywhere in the world.

Read More3D Printed Cutting Tool for Large Transmission Part: The Cool Parts Show Bonus

A boring tool that was once 30 kg challenged the performance of the machining center using it. The replacement tool is 11.5 kg, and more efficient as well, thanks to generative design.

Read MoreRead Next

Infrared Camera Supports Real-Time Process Control for Laser Metal Deposition and Cladding

New Infrared Technologies’ Clamir system provides continuous meltpool monitoring for cladding and directed energy deposition 3D printing.

Read MorePowderCleanse Concept Delivers In Situ Powder Analysis for Metal 3D Printing

A collaborative project developed a prototype solution for measuring particle size distribution on the production floor, as part of the sieving step typical to additive manufacturing processes using metal powders.

Read MoreDEDSmart Tool Harnesses Data in Real-Time for Build Quality Verification

FormAlloy Technologies’ DEDSmart technology for autonomous DED builds and build data logging utilizes enhanced in-situ monitoring and control, and the power of data, to complete builds autonomously while data logs are automatically exported enabling Digital Build Certification.

Read More