DSM, Nexa3D Collaborate to Fast Track Laser Sintering Materials

Nexa3D to include DSM’s PBT laser sintering material in its Quantum Laser Sintering QLS 350 starter kit beginning in early 2021.

Share

Read Next

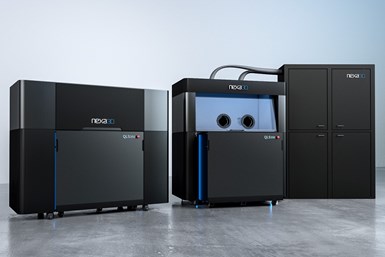

Nexa3D’s QLS-350 system

Royal DSM and Nexa3D are partnering to fast track the availability of Nexa3D’s QLS-350 systems with DSM’s supply chain-approved laser sintering powders for series production. As part of this collaboration, Nexa3D plans to include DSM’s PBT laser sintering material, Arnite T AM1210 (P), with every Quantum Laser Sintering QLS 350 system it sells commercially beginning in early 2021.

According to DSM, Arnite T AM1210 (P) is the first polybutylene terephthalate (PBT) powder commercially available for series production of industrial and automotive electronics. Since its launch in 2019, it has become known for its series production performance in making end-use parts, such as automotive electronics and applications, that need to function under high temperatures. Arnite T AM1210 (P) has the same dielectric properties as material used in injection molding processes, making it a material familiar to engineers. Developed for a wide sinter window, the powder is easy to print, environmentally friendly with a high reuse rate of >60% and is recyclable to the extent that the material can be brought back to the powder bed process.

The use of laser sintering PBT materials is expected to increase exponentially over the next decade, driven primarily by accelerating innovations in the automotive, electrical and electronics industries. This trend is apparent in the automotive industry, where there is a need for lighter, more sustainable, lower maintenance materials. The use of engineer-grade materials such as PBT is expected to increase due to the need to minimize issues surrounding the corrosion of metals and their associated high costs.

This partnership underscores both companies’ commitment to accelerate the adoption of sustainable AM for series production of electrical connectors, automotive electronics and lighting applications through collaborations that are designed to unlock the full potential of additional performance polymers for additive manufacturing.

Related Content

-

What Is the Role of Sintering in Binder Jetting? (Video)

And how strong are green parts prior to sintering? Filmed at HP, here is a look at sintering, including the shrinkage from green to sintered binder jet parts.

-

Freeform: Binder Jetting Does Not Change the Basics of Manufacturing

Rather than adapting production methodologies to additive manufacturing, this Pennsylvania contract manufacturer adapts AM to production methodologies. In general, this starts with conversation.

-

AMGTA Research Demonstrates Sustainable Benefits of Binder Jet 3D Printing

Research from the Yale School of the Environment shows substantial reduction in GHG over traditional casting methods.