Air Force Research Laboratory, Boeing and Thermwood Partner on Low Cost Responsive Tooling Program

The Air Force Research Laboratory, Boeing and Thermwood partnered to evaluate the functionality of Vertical Layer Printing (VLP) using high temperature, autoclave-capable materials on a Large Scale Additive Manufacturing (LSAM) machine.

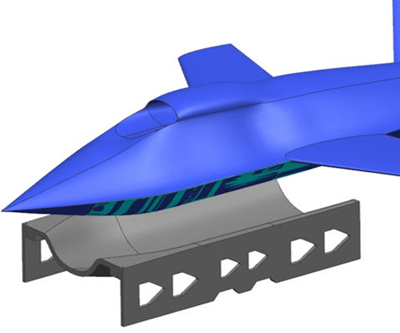

The Air Force Research Laboratory’s conceptual aircraft and full-scale tool, developed to promote low cost responsive tooling for composites.

A new demonstration tool made via 3D printing is highlighting additive manufacturing’s (AM’s) capabilities for large composites. The United States Air Force Research Laboratory (AFRL) Manufacturing and Industrial Technology Division (ManTech) has shown interest in large scale polymer-based additively manufactured (AM) composite cure tooling. Boeing submitted an idea to ManTech’s Open BAA to evaluate the current state of additive manufacturing technology with respect to the fabrication of low cost, autoclave capable tools for the production of composite aerospace components. The initial demo tool is for an AFRL concept aircraft fuselage skin. Boeing contracted Thermwood Corp. to manufacture the demo tool using its Large Scale Additive Manufacturing (LSAM) machine.

The Thermwood LSAM machine offers an innovative additive manufacturing capability with its Vertical Layer Printing (VLP). The Vertical layer Printing AM process provides a significant cost benefit by increasing the size of components that can be printed, thus reducing assembly cost for large tools. To validate the VLP process using high temperature, autoclavecapable materials, Boeing and AFRL chose to 3D print a section of the large tool to evaluate the LSAM functionality. The Mid-Scale tool was printed on Thermwood’s LSAM Additive Manufacturing Demonstration machine in Southern Indiana using a 40-mm print core running 25% carbon fiber reinforced Polyethersulfone (PESU).

The Mid-Scale tool being 3D printing on Thermwood’s Large Scale Additive Manufacturing (LSAM) machine.

The initial test tool has the same width, height and bead path as the final mold, incorporates all major features of the final mold, but is compressed in length being only 4 feet long. The final tool will be over 10 feet long. The Mid-Scale tool set a milestone achievement as the first high temperature tool printed using the VLP system. The Mid-Scale tool required 5 hours, 15 minutes to print with a print weight of 367 lbs. After final machining, the tool was probed for surface profile and tested for vacuum integrity. The tool passed a room temperature vacuum test and achieved dimensional surface profile tolerances.

Machining (left) and probe (right) operations on a Thermwood LSAM machine.

The program is progressing to the next step, producing a full-size tool. The Full-Scale tool will weigh approximately 1,400 lbs and require 18 hours to print. Boeing and the Air Force are carefully documenting all operational parameters of the project to transition the technology to production programs. Additive manufactured autoclave tooling offers significant advantages over traditional methods of producing these tools. 3D printed tooling is less expensive and can be fabricated in days or weeks rather than months.

AFRL is very interested in tooling approaches for the Low-Cost Attributable Technology (LCAAT) program which has a goal to break the cost growth curve and field new systems faster. AFRL Program Manager Andrea Helbach says, “We are interested in additively manufactured tooling’s ability to reduce the cost and time to procure autoclave capable tooling. Additionally, AM tooling supports changes in vehicle design with minimal non-recurring expenses.”

“Future fielded low cost, but capable UAV’s will need a responsive materials and manufacturing processes strategy” says Craig Neslen, LCAAT Initiative Manufacturing Lead. “Additive manufactured composite tooling is one of many technologies being evaluated to ensure the industrial base can handle future manufacturing surge requirements as well as accommodate periodic system tech refresh activities which could necessitate minor vehicle design changes at an acceptable cost.”

Related Content

“Mantis” AM System for Spacecraft Uses Induction for Deposition

The metal 3D printing system melts wire without lasers. 30-foot-diameter parts are built on a rotary-feed system that eliminates the need for a large machine frame or gantry.

Read MoreAircraft Ducts 3D Printed in Composite Instead of Metal: The Cool Parts Show #68

Eaton’s new reinforced PEKK, tailored to aircraft applications, provides a cheaper and faster way to make ducts compared to formed aluminum.

Read MoreBig Metal Additive: The Difference Between a Shape and a Part Is Quality

Preparing to scale directed energy deposition to ongoing full production is not a technological challenge: DED is ready. But it is an organizational challenge, says the company founder. Here is what it means to implement a quality system.

Read MoreEvaluating the Printability and Mechanical Properties of LFAM Regrind

A study conducted by SABIC and Local Motors identified potential for the reuse of scrap reinforced polymer from large-format additive manufacturing. As this method increases in popularity, sustainable practices for recycling excess materials is a burgeoning concern.

Read MoreRead Next

Thermwood’s Vertical Layer Printing Turns AM on Its Side

Vertical Layer Printing (VLP) 3D prints layers perpendicular to the floor, extending Z height to the length of the print bed — as long as 40 feet.

Read MoreLarge-Format Additive Manufacturing: Viable for Autoclave Tooling?

SABIC and the University of Dayton Research Institute explore the potential of using large-format additive manufacturing (LFAM) technology for creating autoclave tooling used in manufacturing aerospace composite parts.

Read MoreBike Manufacturer Uses Additive Manufacturing to Create Lighter, More Complex, Customized Parts

Titanium bike frame manufacturer Hanglun Technology mixes precision casting with 3D printing to create bikes that offer increased speed and reduced turbulence during long-distance rides, offering a smoother, faster and more efficient cycling experience.

Read More