News

Kennametal Joins GE Additive Beta Partner Program

As part of the program, Kennametal will work with GE Additive to identify, design and scale specific applications for serial production on GE’s binder Jet system to leverage its cemented tungsten carbide additive materials.

Read MoreTo the Moon and Beyond with Additive Manufacturing

Aerojet Rocketdyne uses metal 3D printing technology from Velo3D to make a critical flight component lighter, smaller, and much less expensive than its predecessors.

Read MoreAir Force Awards $1.5M Contract to Optomec for Additive Repairs

Company says additive repair solution for F35 large titanium blisk has potential to reduce costs by 80% and save tens of millions annually.

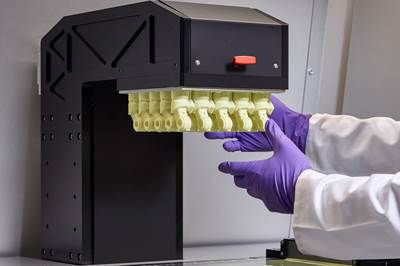

Read MoreFormlabs Resins for Creating Tough, Durable 3D Printed Parts

Company says new resins are high-performance polyurethane materials for additive manufacturing which are said to offer users more design freedom, reduced production costs and increased workflow efficiencies.

Read MoreBertram Dental Lab Uses 5 SLM 3D Printers for Denture Print Service

Bertram Dental Lab partners can simply upload their completed .stl design files through the service portal to access direct manufacturing for cobalt chrome removable partial dentures.

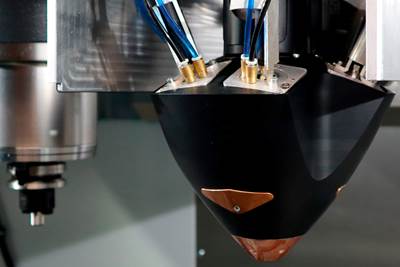

Read MoreCNC Engineering Integrates 3D Printing Solutions With CNC Machine Tools

CNC Engineering and Meltio have collaborated to design a solution that combines the power and reliability of FANUC CNC with cutting edge additive manufacturing technology.

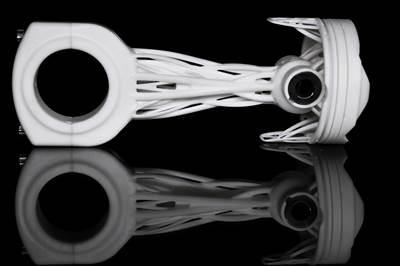

Read MoreXJet Produces First Entirely Ceramic Piston for Chaos Ultracar

Company says no other technology could achieve the accuracy and complexity required to create Spyros Panopoulos Automotive’s lightweight ceramic design.

Read MoreAdmatec’s Larger Integrated Binding/Sintering Furnace for Ceramic 3D Printing

Company scales up for more efficient mass customization and serial ceramics 3D printing production lines.

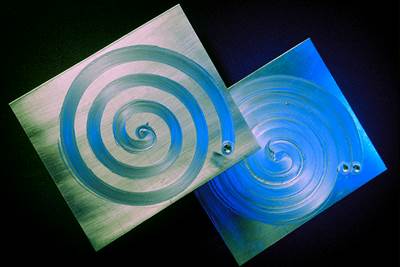

Read MoreCollaborators Work on Subsurface Project for Cold Plate Manufacturing

The project goal is to offer a new process head enabling CoreFlow on any CNC system via retrofit integration. In addition to the ability to alternate between milling and CoreFlow, the hybrid CNC will also feature optional subsurface inspection using the Ambit Wave ultrasonic inspection head developed by HMT.

Read MoreWayland Additive’s Calibur3 for Stress-Free Metal Parts

Rapid + TCT 2022: The system features the NeuBeam hot part process rather than a hot bed process, which means it can efficiently create parts that are free of residual stresses because the high temperatures are only applied to the part and not the bed.

Read More