CNC Engineering Integrates 3D Printing Solutions With CNC Machine Tools

CNC Engineering and Meltio have collaborated to design a solution that combines the power and reliability of FANUC CNC with cutting edge additive manufacturing technology.

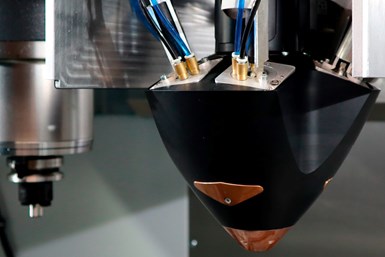

Meltio engine CNC installation. Photo Credit: CNC Engineering

CNC Engineering Inc. will now play a key role in the distribution, integration and support of the Meltio metal 3D additive manufacturing (AM) solutions for FANUC CNC and robotic systems in the U.S. market.

According to CNC Engineering Inc., it specializes in the integration and support of FANUC CNC machine tool retrofits, Renishaw probe and laser systems, rotary tables and additional axes, FANUC Robots and now Meltio solutions.

Meltio is said to take metal AM to the next level by developing high-performance, affordable and easy-to-use metal AM solutions using wire laser metal deposition (LMD) technology, which the company says is the safest, cleanest and most affordable metal feedstock in the market.

CNC Engineering and Meltio say they have collaborated to design a solution that combines the power and reliability of FANUC CNC with cutting edge AM technology. This hybrid additive and subtractive manufacturing solution is said to have several advantages, including offering one of the most affordable hybrid manufacturing solutions. It is also said to provide production savings as it offers nearly 100% material utilization. It can also generate complex geometries in a single process and combine different materials into a single part. Users can also utilize AM in their shops by taking advantage of existing machines, thereby saving floor space.

Related Content

-

JuggerBot 3D Awarded $4 Million by Air Force to Develop Large Format Hybrid Additive System

The project focuses on advancing the ability to print a thermoset composite material that can transform the way an aircraft structure is designed, fabricated and sustained for limited-life aircraft.

-

Machine Tool Drawbar Made With Additive Manufacturing Saves DMG MORI 90% Lead Time and 67% CO2 Emission

A new production process for the multimetal drawbar replaces an outsourced plating step with directed energy deposition, performing this DED along with roughing, finishing and grinding on a single machine.

-

Video: Robot Machining Will Complement Robot DED

Robots can do additive manufacturing. Can they do hybrid manufacturing? Precision milling of metal using a robot offers this promise.