Collaborators Work on Subsurface Project for Cold Plate Manufacturing

The project goal is to offer a new process head enabling CoreFlow on any CNC system via retrofit integration. In addition to the ability to alternate between milling and CoreFlow, the hybrid CNC will also feature optional subsurface inspection using the Ambit Wave ultrasonic inspection head developed by HMT.

Share

Read Next

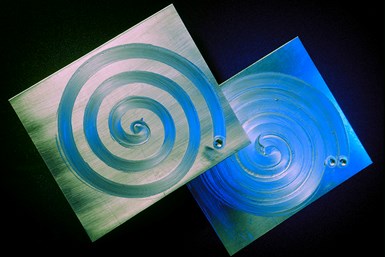

Photo Credit: Hybrid Manufacturing Technologies

Hybrid Manufacturing Technologies (HMT), The Welding Institute (TWI) and PSL Assemblies have joined forces on a SubSurface project to mature a method TWI developed to revolutionise cold plate manufacturing.

According to the partners, the current cold plate manufacturing process is slow, costly and complicated, which often results in poor yields due to quality issues. CoreFlow is a solution TWI developed in 2016, derived from friction stir welding (FSW), which it says is an innovative solid-state process that creates subsurface networks within metal structural elements. It is said that integrating this approach into a hybrid CNC could overcome the cold plate manufacturing challenges by enabling production of cold plates in a single setup.

Although early work has demonstrated the potential of the CoreFlow process, it has been undertaken on dedicated R&D friction stir equipment which is not representative of the platforms typically found in this industry, the group says. Furthermore, it is not always optimal for postprocessing steps such as finish machining or inspection.

To enable efficient cold plate manufacture in a single setup, HMT teamed up with TWI to produce a solution usable in mainstream CNC machines. The solution targets adoption at a fraction of the current cost (~5x capital investment reduction) by leveraging the wide availability of CNC milling machines.

The group says the SubSurface project will develop and subsequently offer a new process head to enable CoreFlow on any CNC system via retrofit integration. In addition to the ability to alternate between milling and CoreFlow, the hybrid CNC will also feature optional subsurface inspection using the Ambit Wave ultrasonic inspection head developed by HMT.

“We are pleased to be working with TWI and PSL to align our collective technical prowess and market knowledge,” says Dr. Jason Jones, HMT CEO and co-founder. “Together we will deliver a step change in capability and improved cost-effectiveness for the next generation of thermal management solutions.”

HMT has been creating solutions in hybrid and additive manufacturing, enabling 3D printing on machine tools. It has developed a line of compact interchangeable deposition and inspection heads with integration methods to extend the capabilities of CNCs and robots, thereby accelerating the adoption of the next wave of digital manufacturing.

Related Content

-

Machine Tool Drawbar Made With Additive Manufacturing Saves DMG MORI 90% Lead Time and 67% CO2 Emission

A new production process for the multimetal drawbar replaces an outsourced plating step with directed energy deposition, performing this DED along with roughing, finishing and grinding on a single machine.

-

DMG MORI: Build Plate “Pucks” Cut Postprocessing Time by 80%

For spinal implants and other small 3D printed parts made through laser powder bed fusion, separate clampable units resting within the build plate provide for easy transfer to a CNC lathe.

-

3D Printed Cutting Tool for Large Transmission Part: The Cool Parts Show Bonus

A boring tool that was once 30 kg challenged the performance of the machining center using it. The replacement tool is 11.5 kg, and more efficient as well, thanks to generative design.