One-Offs Without Tradeoffs

Does it have to be expensive to produce a one-off part? Does the one-off have to fall short of the manufactured part’s properties? A Boston-area 3D printer maker has an idea for how to produce components that are both low quantity and industrial quality.

Share

Here is Greg Mark’s summary of the hope he has for his startup company: “We want to provide the cheapest way to make just one of something.”

His company, MarkForged in Somerville, Massachusetts, manufactures a desktop 3D printer with a distinctive capability that separates it from other 3D printers, and even from industrial additive manufacturing machines. More on that capability in a bit.

The hope he expresses is significant to machine shops—and to discrete-part manufacturers in general—because these manufacturers all routinely face the challenge of making one-off parts. Prototypes are one example, but even manufacturers that rarely make prototypes still face the challenge, because part producers have a need for tooling. Custom workholding elements such as soft jaws and fixture components probably account for the type of one-off part that machine shops create most frequently. Because of the setup time and human attention they require, these one-off parts are expensive.

3D printing would seem to be the solution to this challenge. With 3D printing, there are no clamps or cutting tools to set up, there is no CNC programming, and if the right material is already in the machine, then there is little prep time. That is why 3D printers of various types are successfully being applied to making tooling and other one-off items.

But there are some problems. In general, 3D printers of the lower cost, desktop variety are not well-suited to “manufacturing” in the strict sense of reliably making a useful object that matches a CAD model. First, these printers make parts out of plastic, and while the output in some cases is a strong and durable plastic, the performance and properties of parts made this way still do not reach what metal can provide. In addition, the distortion of these plastic parts as they form and cool—an effect that is unimportant if the part is a design prototype or simple object—often leads to dimensional discrepancies from the model that are too great for precise applications.

At the opposite extreme from these desktop machines are additive manufacturing machines making dense metal parts. These machines can produce durable functional parts and can hold engineering tolerances, but given their price, this option often does not qualify as an inexpensive choice for making a one-off part.

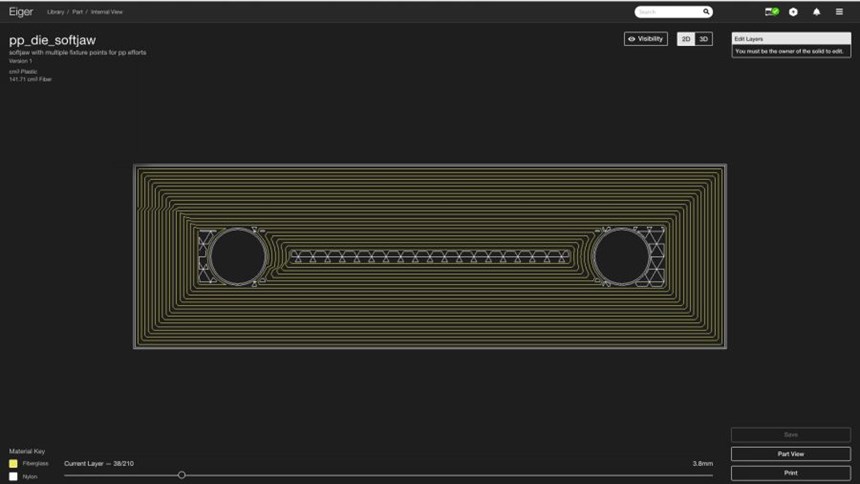

The distinctive capability of the MarkForged Mark One machine is this: It lays down fiber reinforcement within the 3D-printed plastic parts. Spooled carbon fiber or Kevlar is part of the mechanism of the machine. A software interface gives a recommendation for the location and arrangement of fiber reinforcement within the model, and also allows users to override this recommendation by manually indicating where the reinforcement should be placed and how much should be used.

Mr. Mark is the company’s president and also the inventor who led the development of this machine. The fiber reinforcement provides two benefits, he says. The first is precision. The machine itself is precise, printing forms onto a flat metal build plate. The fiber’s stiffness then preserves this flatness by supporting the part against its own tendency to distort. “In fiber versus plastic, fiber wins,” he says.

The second benefit of the fiber is strength. A plastic part possessing something like the optimal level of carbon or Kevlar achieves the strength-to-weight ratio of aluminum. On the day I visited MarkForged, one of the company’s employees happened to be making the pedal crank for a mountain bike on the 3D printer. This is a part that typically would not be trusted to plastic, but the fiber reinforcement gave this plastic part the strength it needs to handle the (pardon the pun) cyclical loading.

The price of the MarkForged printer, around $5,500, is high compared to other desktop printers. Mr. Mark says this is because of the intended application. The printer’s components and movements were engineered with the expectation that the machine would make functional parts. Accuracy is limited by the imprecision of the bead of melted plastic to about ±0.005 inch, but accuracy is not limited by the error of the machine positioning or the uncertainty of the part’s distortion, both of which are controlled more narrowly. In short, this printer is not for design prototypes, but instead for functional prototypes or short-run production parts.

Or tools. Much of MarkForged’s own Boston-area headquarters is the machine shop in which components of the company’s printer are produced. In this shop, the employees have found instances not only where 3D printing was the cheaper choice for making tooling, but also where the 3D-printed tool actually did the job better than an aluminum tool.

Meanwhile, one of the printer’s early adopters demonstrates how the promise of 3D-printed tooling also makes sense beyond machining.

Tooling for Plastics Production

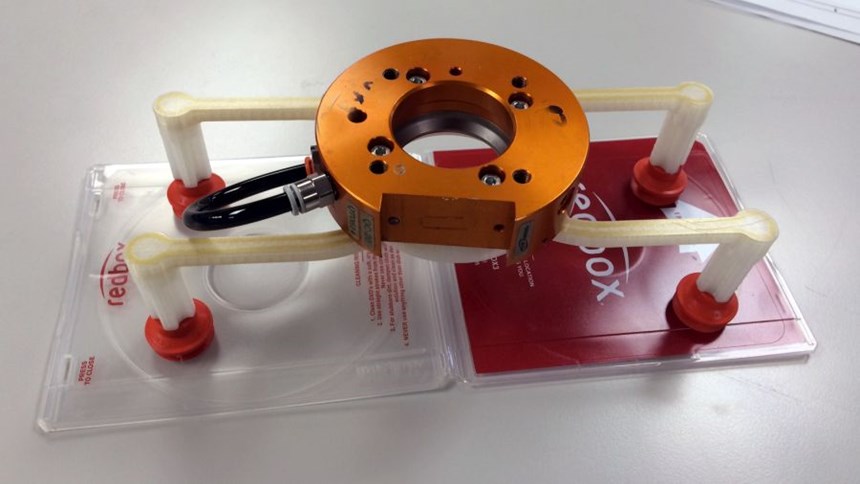

When the Mark One printer was introduced last year, the initial production run was funded through pre-orders. One of those pre-order customers was Evco Plastics of DeForest, Wisconsin. This custom injection molder had been using 3D printing for years, but using it primarily for design prototypes intended just to verify a part’s appearance. The use of 3D printing for functional objects was limited to non-demanding applications such as coordinate measuring machine fixtures. Since receiving the Mark One, however, the Wisconsin molder has used this machine almost exclusively for functional parts, including custom gages and end-of-arm tooling, items that typically have been built out of components made through machining.

Mark McDonald, Evco’s design manager, was involved in the company’s decision to buy the printer. He admits that the tooling made out of traditional metal parts was working well enough, to the extent that there was no perceived need for a printer such as the Mark One. However, a desire to explore the possibilities of new manufacturing technology is part of the culture of the company and part of the personal interests of company leaders. Mr. McDonald says, “When I saw a news item announcing a printer with fiber placement capability, I showed it to our company president, who agreed quickly that we ought to give this a try.” The price was low enough that it was easy to take a chance to see what the printer might do. As a result, the company obtained an entirely new option for making tooling.

Not every tooling component requires fiber reinforcement, Mr. McDonald says. The plastic alone is often rugged enough even for production tooling. But many components really do need the reinforcement.

Handheld gages are an example. These gages have historically been made from metal, in part because the brusque movements of efficient production inevitably mean that the gages are handled roughly and sometimes dropped. 3D printing with fiber reinforcement makes it possible to create a durable gage in one step, without assembling various parts, because 3D printing generates the gage’s handle, structure and contoured form (matching some curved surface of a molded part) all in one piece in a single build. The printed gage’s design is often better, in fact, because features such as air lines can be grown into the part instead of being snaked in through assembly. The printed gage is also often better because of its weight—perhaps the most promising improvement of all. Though gages printed on the Mark One have the same strength-to-weight ratio as aluminum, they are lighter than aluminum gages because fasteners and extra stock for assembly can be eliminated. Thus, when one of these new gages is dropped, there is less risk of the gage’s user being injured.

The printer does have limitations, says Mr. McDonald. So-called 3D printing is actually 2-½D printing, he notes, because parts are built by stacking flat layers. Not all forms lend themselves to taking shape in this way, particularly on the Mark One, which lacks a capacity for soluble support structures that might be used to buttress awkward forms while the growth is incomplete. Yet that limitation impedes him only infrequently, he says. The limitation that stops him more often is just the small size of the machine. A build box size of 12 by 6.25 by 6.25 inches makes the printer too small for the robotic end-of-arm tooling that Evco’s larger injection molding machines require. If this machine’s envelope were bigger, then a lot more robots in Evco’s plant would be using 3D-printed tooling.

The Prototyping Promise

The history of most 3D printing machines began with prototyping, but Mr. Mark says the origin of his own printer actually did start with the need to make a functional part. A product he had worked to develop in a previous role was an electronics device used by the military. The device’s case could not be metal, but it had to be rugged enough for battlefield use, and only a small number of these cases was needed. Mr. Mark realized that finding a way to generate custom, fiber-reinforced structures would provide the answer for a need such as this.

The purely mechanical aspect of making that idea real was straightforward. Placing fiber in plastic is not that difficult. The real challenge, he says, was obtaining control over just where inside the part model this placement occurs. That is why the unsung hero of the printer is the software that lets the user dictate where the fiber goes within a given form. Software engineering represented a considerable share of the engineering work that went into the printer’s development.

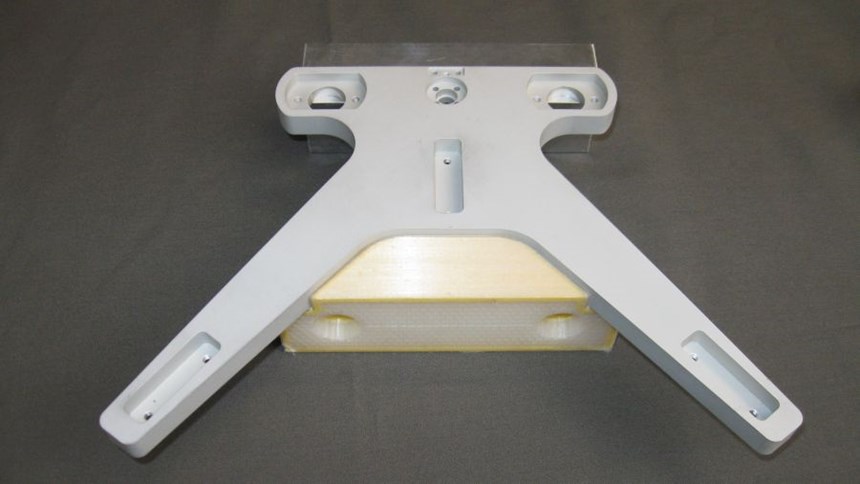

It was during that development that the company’s staff discovered the machine’s usefulness for making tooling. In fact, the discovery came quite late. Because of a necessary but awkwardly last-minute design change, 50 pieces of the brace supporting the printer’s build plate—pieces that had already been anodized—had to be remachined. Company employees initially used aluminum soft jaws to hold the parts for machining, but they stopped when the metal jaw scraping the part ruined the look of what would be a visible surface. Instead, they 3D printed a jaw, creating tooling that not only held the part but also protected it. The lesson: Printed tooling is good for holding work, but it is particularly good for holding re-work.

Other applications like this will be discovered, Mr. Mark says. It is part of the nature of 3D printing to turn up new uses, because 3D printing makes parts that are otherwise impractical enough that they wouldn’t previously have been considered. “In the 80-20 analysis of what parts to make, we are the 20,” he says. The real promise of 3D printing is not just that previously unthinkable parts become thinkable, but that they become easy to achieve.

And that brings us back to prototyping. Given a 3D printer that is able to produce precise and durable parts, he says, the use of 3D printing for prototyping can go far beyond design and far beyond look-and-feel prototypes to extend into functional parts. Whereas prototypes produced on the lowest-cost 3D printers might not be durable enough to be functional, and prototypes made on machine tools might be too expensive to allow this prototyping to continue for long, here is a prototyping option that potentially offers neither disadvantage.

The availability of such an option means that designs can remain in CAD longer before going into production. Engineers refining part designs can proceed longer through iteration after iteration. They can keep trying design changes with functional prototype after functional prototype, and possibly avoid altogether the kind of rework that was necessary with MarkForged’s initial run of 50 braces.

Related Content

Understanding PEKK and PEEK for 3D Printing: The Cool Parts Show Bonus

Both materials offer properties desirable for medical implants, among other applications. In this bonus episode, hear more from Oxford Performance Materials and Curiteva about how these companies are applying PEKK and PEEK, respectively.

Read More3D Printed Spine Implants Made From PEEK Now in Production

Medical device manufacturer Curiteva is producing two families of spinal implants using a proprietary process for 3D printing porous polyether ether ketone (PEEK).

Read More6 Trends in Additive Manufacturing Technology at IMTS 2024

3D printers are getting bigger, faster and smarter. But don’t overlook the other equipment that the AM workflow requires, nor the value of finding the right supplier.

Read MoreAircraft Ducts 3D Printed in Composite Instead of Metal: The Cool Parts Show #68

Eaton’s new reinforced PEKK, tailored to aircraft applications, provides a cheaper and faster way to make ducts compared to formed aluminum.

Read MoreRead Next

Getting to Production Faster with 3D-Printed Press Brake Tooling

A case study from Centerline Engineered Solutions demonstrates that a 3D-printed die and punch can withstand press brake forces, providing a cheaper, faster path to production.

Read MoreVideo: 3D Printing with Carbon Fiber

Make parts as strong as metal on a desktop machine, the company says.

Read MorePostprocessing Steps and Costs for Metal 3D Printing

When your metal part is done 3D printing, you just pull it out of the machine and start using it, right? Not exactly.

Read More