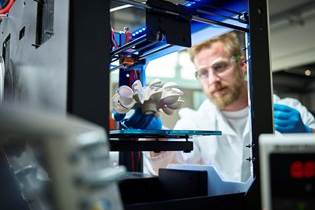

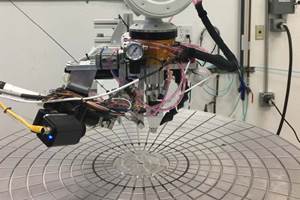

The 3D printer itself is typically only one part of the investment in additive manufacturing. Nearly every process and application will require support beyond the printer and material.

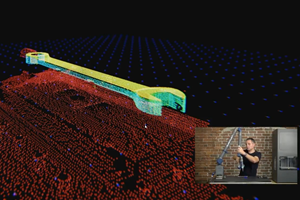

AM users may need to invest in new software products such as slicing programs, generative design or topology optimization, and/or build simulation.

The specific 3D printing process and system used will dictate what hardware is needed in addition to the 3D printer. For example, here are simplified equipment lists for several common AM methods:

Metal Powder Bed Fusion |

Metal Binder Jetting |

Polymer Powder Bed Fusion |

Photopolymerization |

| Shielding gas such as argon | Sieving and powder handling equipment | Sieving and powder handling equipment | Resin handling and mixing equipment |

| Sieving and powder handling equipment | 3D printer | 3D printer | 3D printer |

| 3D printer | Debinding station | Vacuum down-draft table for unpacking parts | Parts washing equipment |

| Oven for heat treat | Sintering furnace | Mass finishing equipment such as bead blasting and tumblers | Curing oven |

| Band saw or wire EDM for part cut-off | Machining capacity for finishing | Dyeing equipment | |

| Machining capacity for finishing |

Appropriate safety measures and equipment should not be overlooked, either. Metal 3D printing businesses may need facility-wide measures such as inert gas supply, electrostatic dissipative (ESD) flooring, fire suppression systems and air quality monitoring, as well as personal protective equipment (PPE) for operators such as respirators and flame-resistant clothing.

Polymer 3D printing facilities may need air filtration and ventilation systems to protect personnel from volatile organic compound (VOC) and particle inhalation.