How to Pursue AM Adoption Within an Established Manufacturing Organization

Succeeding with additive manufacturing requires enterprise-wide buy-in and change. EOS describes tactics including a two-team structure: transformation team and implementation team.

Share

For additive manufacturing (AM) to succeed as a mode of production, a company’s executive leadership has to be involved in the shift to AM. This is because additive manufacturing for production is not a one-for-one replacement for other production methods. Instead, in addition to changing manufacturing, AM also changes the possibilities for design, logistics, service and even new product introduction. To view AM adoption as just a manufacturing concern is to hinder it by curtailing its promise. We have written about this.

Now, Fabian Alefeld, consulting manager with additive manufacturing technology provider EOS, has offered what is arguably the next step after the recognition above. Enterprise-wide transformation is a strategy, but in a presentation titled, “From Challenge to Challenger: Your Path to Additive Manufacturing Success” (details below), Alefeld offered tactics. One of the most important tactics is a two-team structure of company staff members advancing additive, consisting of a transformation team and an implementation team.

He says the transformation team includes the CEO, ideally, as well as other executive sponsors, plus representative leaders from different functions within the value chain who have the influence to lead and effect change. The members of the implementation team are also on this team — more on this in a bit. The existence of the transformation team recognizes that a change as sweeping as AM is going to face obstacles and headwinds, particularly unexpected ones, and the pursuit of the strategy will require these challenges to be cleared or persevered, sometimes via action at the executive level.

The implementation team then consists of additive manufacturing’s users and appliers — the personnel within production, engineering, design and other operations who will directly work with this manufacturing technology, become the experts with it and realize its wins, including the small wins. The implementation team reports its successes, findings and (importantly) needs within the transformation team.

Fabian Alefeld of EOS presented on tactics for AM adoption within an established manufacturing enterprise. Watch the presentation here.

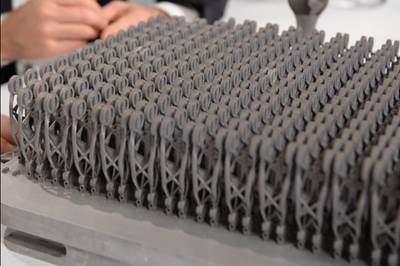

One other simple but important tactic Alefeld describes relates to those small wins. When advancing AM, he says, do not start by pursuing the long-term opportunities. Doing so would be the natural choice, because the scope of AM’s promise informs the vision and provides the reason for the transformative change. However, the far better first step is to solve problems, he says. Find the challenges within existing operations that AM can address — perhaps via a tool made with 3D printing that can simplify an established process. Solving problems demonstrates the promise and wins support, and that support will be valuable for enabling the cultural shift that an enterprise-wide change will ultimately require.

Alefeld gave his presentation during the AM In-Depth educational series within IMTS Spark, the online platform launched in the wake of the covid-related cancellation of this year’s International Manufacturing Technology Show (IMTS). In our Q&A after his talk, I asked him how to choose the right people for the teams, particularly the implementation team. His answer — I am simplifying — is that, in part, they self-select on the basis of their enthusiasm for, and ability to see and express, additive’s promise. Hear his and my exchange as part of the recorded presentation.

IMTS Spark runs through early 2021. Registration for AM In-Depth and all other programming is free. Watch Alefeld’s presentation here.

Related Content

3MF File Format for Additive Manufacturing: More Than Geometry

The file format offers a less data-intensive way of recording part geometry, as well as details about build preparation, material, process and more.

Read MoreHow to Organize for Additive Production: AM Radio #42

Tim Simpson and Peter Zelinski discuss the next steps for succeeding with AM: After technical and process successes come the cultural, organizational and even costing considerations associated with this mode of manufacturing.

Read MoreVideo: What Is Electron Beam Melting (EBM)?

Electron beam melting is the higher-energy metal 3D printing process offering advantages when it comes to productivity and thermal stresses. Here is an introduction to EBM.

Read MoreThe New Misperceptions Of AM: AM Radio #35

Tim Simpson and Peter Zelinski discuss a way additive manufacturing has advanced: The misperceptions have shifted. Knowledge of AM among manufacturers is more sophisticated now. The concerns that inform the perceptions of newcomers have therefore changed.

Read MoreRead Next

The Case for Additive Manufacturing in Production

3D printing may have started out as a rapid prototyping technique, but the machines and materials have matured to the point that production is not only viable, but desirable, in many cases.

Read MoreThe New Normal? Resilient Supply Chains with 3D Printing

We were already headed toward expanded adoption of 3D printing, in HP’s view, when the coronavirus hit. The pandemic’s disruption will only get us there faster.

Read MoreWhat Your CEO Needs to Know About Additive Manufacturing

Additive manufacturing promises to affect far more than manufacturing alone. When evaluating AM, the perspective needed is the view that sees the impacts all across the enterprise.

Read More