Video: What Is Electron Beam Melting (EBM)?

Electron beam melting is the higher-energy metal 3D printing process offering advantages when it comes to productivity and thermal stresses. Here is an introduction to EBM.

Share

What is Electron Beam Melting (EBM)?

Electron beam melting (EBM) is a powder bed fusion metal 3D printing process.

The energy source is an electron beam. Compared to laser powder bed fusion, EBM is a higher-energy additive manufacturing method offering the chance for both greater productivity and greater control over the effects of thermal stresses during 3D printing of the metal.

How Does EBM Work?

- A layer of metal powder is spread across the build area.

- The machine pre-heats the layer of powder

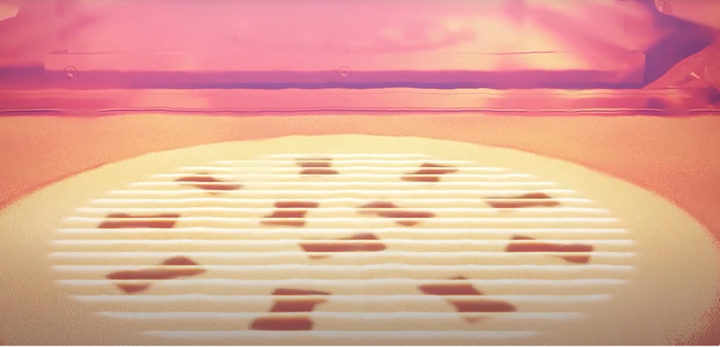

- An electron beam fuses, or melts, the powder together. The powder is melted only in the places needed to build the geometry of the final part.

- The spreading, heating and fusing steps are repeated over and over until a part is created.

- The final build will look like something like a semi-solid block or cake of powder. This block will have all of the pre-heated powder, regardless of whether or not it was melted, with the final solid part or parts inside.

- The parts are removed and depowdered.

Electron beam melting typically takes place inside a machine under vacuum. In the machine is a bed of powder metal that is fused together layer by layer with an electron beam to build a solid metal part.

The electron beam is a higher energy source compared to what’s used in more common laser powder bed fusion and produces very high temperatures.

What Are the Benefits of EBM?

- Safety. The higher energy source makes it possible to use larger diameter metal powder. The heavier powder metal doesn’t pose the same respiratory risk as fine metal powder. With electron beam melting, it's possible to work with the powder, and be around the powder without necessarily needing special safety equipment.

- Less distortion. Electron beam melting takes place within an environment of higher temperature than laser powder bed fusion, which allows for better management over the thermal stresses. That means less warping, less distortion, and potentially better dimensional accuracy. It also means that postprocessing steps like hot isostatic pressing likely won’t be necessary.

- Fewer supports. EBM offers a more stable build. The control over thermal stresses means that it’s not necessary to rely on support structures to anchor the part in place against deformation. The supports are there instead to pin the parts in location for the duration of the build. Support structures can be thinner and, thus, easier to remove.

- Productivity. Compared to laser powder bed fusion, EBM is typically more productive for two reasons. One, the build rate is faster. Two, the ability to stack parts and nest them inside the build chamber allows more parts per print. Reduced reliance on supports also potentially translates into reduced postprocessing needs.

What Are the Drawbacks of EBM?

- Print time. More parts in the build volume potentially translates to longer builds, maybe even days to complete a print.

- Cooling. Preheating all of the build layers produces a finished build that is very hot. It must cool down inside of the machine. This can take several hours, which means the machine cannot be used for another build during that time.

- Powder removal. EBM allows for lots of geometric intricacy while using a larger powder particle size. This can add up to parts with powder trapped inside that can be difficult to get out. Additional postprocessing steps may be needed, such as ultrasonic powder removal and extra inspection.

- Surface finish. Compared to other powder bed fusion processes, electron beam melting produces a coarser surface. Laser powder bed fusion has an advantage when it comes to very fine precision work, but both of these processes produce parts that are very close to net shape.

How Is Electron Beam Melting (EBM) Used?

Applications of electron beam melting (EBM) we have covered include:

- Customized surgical implants

- Mass-produced surgical implants In some instances, such as with hip cup implants, an engineered rough surface has proven beneficial to the patient’s healing.

- Turbine blades, including for power generation

- Wear parts and tooling in hard metals

- Lightweight components for systems used in space, including for the Mars rover

- Intricate machine components, including for an EBM machine

- And even an unusual part for zoo animals

Commonalities we've seen in successes with electron beam melting include hard metals, unusual metals and parts that are large, but also feature thin or delicate sections where control over the deformation of the part is important.

Thank you to Arch Additive and GE Additive for footage used in this video

Related Content

Implicit Modeling for Additive Manufacturing

Some software tools now use this modeling strategy as opposed to explicit methods of representing geometry. Here’s how it works, and why it matters for additive manufacturing.

Read MoreThe New Misperceptions Of AM: AM Radio #35

Tim Simpson and Peter Zelinski discuss a way additive manufacturing has advanced: The misperceptions have shifted. Knowledge of AM among manufacturers is more sophisticated now. The concerns that inform the perceptions of newcomers have therefore changed.

Read MoreVideo: Intelligent Layering Metal 3D Printing at 3DEO

Contract manufacturer 3DEO delivers metal parts using Intelligent Layering, a binder jetting-like 3D printing process the company developed and operates internally. Here’s how it works.

Read MoreUnderstanding PEKK and PEEK for 3D Printing: The Cool Parts Show Bonus

Both materials offer properties desirable for medical implants, among other applications. In this bonus episode, hear more from Oxford Performance Materials and Curiteva about how these companies are applying PEKK and PEEK, respectively.

Read MoreRead Next

3D Printed Turbine Blades for More Efficient Power Generation: The Cool Parts Show #35

Blades made through additive manufacturing promise to let turbines run hotter, and therefore generate more power without increasing in size.

Read More3D Printed Parts on the Mars Perseverance Rover: The Cool Parts Show #23

The Perseverance parts made through additive manufacturing are extreme examples of lightweighting. We have replicas of the 3D printed parts that were sent to Mars.

Read More3D Printed Scapula Customized for Patient: The Cool Parts Show #25

A patient treated for a tumor of the shoulder blade was able to preserve full use of the arm thanks to an implant tailored to the precise form of the original scapula and made through electron beam melting.

Read More.jpg;width=70;height=70;mode=crop)