U.S. Air Force Rapid Sustainment Office Concludes First Ever Advanced Manufacturing Olympics

Nearly $1M in prizes awarded to winners of five competitions related to additive manufacturing. AM editor-in-chief Peter Zelinski co-hosted the Air Force’s week-long event.

Share

Read Next

The U.S. Air Force Rapid Sustainment Office recently concluded its first-ever Advanced Manufacturing Olympics, a virtual event bringing together a broad community of experts from industry, academia and government to explore new possibilities for how advanced manufacturing, with particular focus on additive manufacturing (AM), can be deployed across the Department of Defense and the Air Force. The event, which was held October 20-23, 2020, and included live broadcasts throughout these days, featured technology demonstrations, high-profile speakers from both industry and military, virtual networking opportunities and five technical challenges. The co-hosts were former astronaut Leland Melvin and Peter Zelinski, the editor-in-chief of this site and Additive Manufacturing magazine.

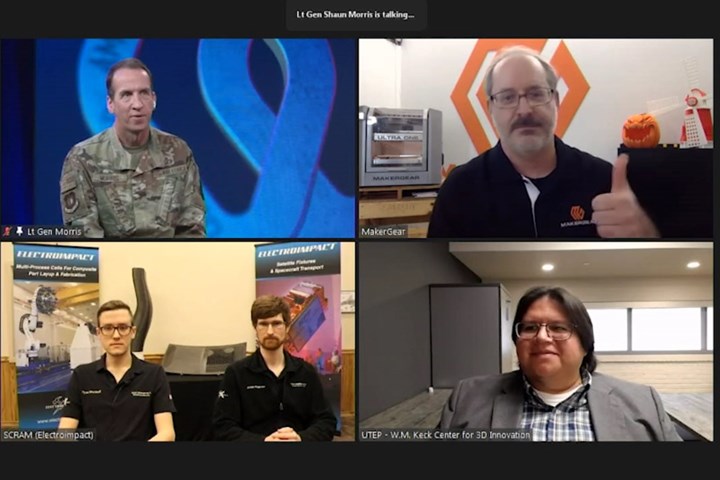

Air Force Lt. Gen. Shaun Morris speaks with the winners of the TDP Relay, one of five competitive events focused on additive manufacturing that were part of the Advanced Manufacturing Olympics. Photo Credit: Still from video by Air Force Rapid Sustainment Office.

According to Lt. Gen. Shaun Q. Morris, Commander of the Air Force Life Cycle Management Center and Program Executive Officer for the Rapid Sustainment Office, “The Advanced Manufacturing Olympics is an important step in the U.S. Air Force and Space Force’s ability to unleash and harness the power of innovation to drive reliability and reduce costs of our legacy systems. Seventy percent of the cost of our weapons systems is in sustainment. Our sustainment enterprise is what makes us ready to fight on any given day. AMO was critical in helping us find new talent and push the envelope into technology like 3D printing, predictive maintenance and reverse engineering.”

Event speakers included Barbara M. Barrett, Secretary of the Air Force; Gen. Charles Q. Brown, Jr., Chief of Staff of the Air Force; and Gen. John W. Raymond, Chief of Space Operations of the U.S. Space Force. Other speakers featured were Sebastian Thrun, founder of Google X; Brad Keselowski, NASCAR Cup Series driver and founder of Keselowski Advanced Manufacturing; and Christine Furstoss, chief technology officer, GE Additive.

The Advanced Manufacturing Olympics included five Technical Challenges designed to address some of the Air Force’s most significant sustainment issues. Sixty-four teams representing a cross-section of participants among startups, established companies and universities, from across the U.S. and Canada, were selected to share their solutions specific to real-world barriers in the Air Force’s ability to realize the full benefits of advanced manufacturing.

“The Technical Challenges were designed to spark innovation, collaboration and technological evolution in advanced manufacturing and push the boundaries for the U.S. Air Force,” said Nathan Parker, Deputy Program Executive Officer for the RSO. “The teams who competed all showed incredible innovation and passion for solving these barriers in the Air Force’s ability to realize the full benefits of advanced manufacturing.”

Additive Manufacturing's own Peter Zelinski was one of the co-hosts of the Advanced Manufacturing Olympics, which was broadcast live from a studio near Wright-Patterson Air Force Base in late October. Photo Credit: Still from video by Air Force Rapid Sustainment Office.

Teams competed for chances to win part of nearly $1M in cash prizes to help continue development of their winning solutions. For each of the five Technical Challenges, the prizes were $100,000, $50,000 and $40,000 for first, second and third place, respectively. The five Technical Challenges were judged by 25 subject matter experts from academia, the U.S. Military (Air Force, Army and Navy), the Federal Aviation Administration, Ford, Amazon, and aerospace and defense companies.

The five Technical Challenges and their first-place winners include:

TDP Relay: The Air Force is constantly looking for better performing, more cost effective and more reliable technology to produce parts required by field units. The goal of this challenge was to recreate a 3D printed part from an existing technical data package — essentially to take a component that had been successfully 3D printed one time and quickly demonstrate accurate, efficient 3D printing on what might be a different printing platform from the original. MakerGear earned first place for printing parts using its M3 printer, a material extrusion (FFF) machine using consumer-grade PLA.

Box of Parts Floor Exercise: 3D printing is revolutionizing parts availability by providing a ready option for reengineering broken parts or parts that don’t have existing drawing packages, but the key to making use of this capability is obtaining the part data. The goal of this challenge was to identify automated or hands-free scanning options for rapid and accurate reverse engineering. Wichita State University’s National Institute for Aviation Research (NIAR) earned first place for its demonstration of accuracy on parts reverse engineered using the Faro 8-Axis Quantum5 FaroArm and FAROBlu Scanner.

Material Hurdles: Aluminum is a metal widely used in the Air Force’s sustainment components, but it presents challenge when applied in 3D printing. The goal of this technical challenge was to identify and demonstrate new aluminum materials that will further additive manufacturing. Elementum 3D earned first place for its A7050-RAM2 aluminum alloy applied in an EOS M290 printer to replace the 7075 aluminum alloy susceptible to stress corrosion cracking.

Approval Sprints: Advanced manufacturing technologies are capable of rapid production for sustainment; however, it is difficult to exploit these capabilities without radical improvement to Air Force certification methods and timelines in the approval of new materials, processes and components. The goal of this challenge was to deliver a polymer AM replacement solution for rapid deployment of a specified F-16 aircraft component. Stress Engineering Services, Inc., Origin, and nTopology earned first place for performing daily design iterations and delivering an optimized clamp design produced via digital light processing (DLP) with Henkel Loctite material rated for Flame Smoke & Toxicity, using a data-driven approval strategy with an AI engine at its core to provide a feedback loop driving continuous improvement of part, material and process performance.

Supply Chain Marathon: In the last few years, additive manufacturing has moved far beyond its original prototyping applications and is now used in supply chain management (SCM). The goal of this challenge was to develop the use of novel advanced manufacturing concepts coupled with innovative SCM approaches to propose the best basing strategy that satisfies the most warfighter requirements and delivers parts on-time and on-schedule. SIMBA Chain earned first place for demonstrating how the use of its self-contained Rapid Additive Manufacturing Lab, which includes all the components and resources necessary for additive manufacturing, could support military wartime operations. From producing aircraft spares, making runway repairs or printing personnel protective equipment (PPE) to protect deployed Airmen from COVID-19 spread, SIMBA Chain painted an impressive picture of what advance technology can do to change the supply chain and enhance readiness levels.

To learn more about the Advanced Manufacturing Olympics, as well as see event recaps and video of all the sessions, visit the U.S. Air Force Rapid Sustainment Office.

Related Content

How Norsk Titanium Is Scaling Up AM Production — and Employment — in New York State

New opportunities for part production via the company’s forging-like additive process are coming from the aerospace industry as well as a different sector, the semiconductor industry.

Read MoreAdditive Manufacturing Is Subtractive, Too: How CNC Machining Integrates With AM (Includes Video)

For Keselowski Advanced Manufacturing, succeeding with laser powder bed fusion as a production process means developing a machine shop that is responsive to, and moves at the pacing of, metal 3D printing.

Read MoreVideo: For 3D Printed Aircraft Structure, Machining Aids Fatigue Strength

Machining is a valuable complement to directed energy deposition, says Big Metal Additive. Topology-optimized aircraft parts illustrate the improvement in part performance from machining as the part is being built.

Read MoreWhy AM Leads to Internal Production for Collins Aerospace (Includes Video)

A new Charlotte-area center will provide additive manufacturing expertise and production capacity for Collins business units based across the country, allowing the company to guard proprietary design and process details that are often part of AM.

Read MoreRead Next

Alquist 3D Looks Toward a Carbon-Sequestering Future with 3D Printed Infrastructure

The Colorado startup aims to reduce the carbon footprint of new buildings, homes and city infrastructure with robotic 3D printing and a specialized geopolymer material.

Read MoreCrushable Lattices: The Lightweight Structures That Will Protect an Interplanetary Payload

NASA uses laser powder bed fusion plus chemical etching to create the lattice forms engineered to keep Mars rocks safe during a crash landing on Earth.

Read MoreProfilometry-Based Indentation Plastometry (PIP) as an Alternative to Standard Tensile Testing

UK-based Plastometrex offers a benchtop testing device utilizing PIP to quickly and easily analyze the yield strength, tensile strength and uniform elongation of samples and even printed parts. The solution is particularly useful for additive manufacturing.

Read More