The Right Design, Material and Machine Combination Takes the Risk Out of 3D Printing Molds

Full-service design and mold delivery, moldmaking materials, and a low-cost, high-precision printer minimize the technical risk of 3D-printed mold tryout.

Bob Zollo believes we’ve been doing it all wrong: using the wrong materials, building inaccurate machines and improperly designing parts for additive manufacturing. Rather than selecting these parameters from existing options, Zollo has actively developed 3D printing materials, technology and design guidelines specifically for 3D-printed injection molds.

Zollo is a founder and CEO of Avante Technology, a new Cheyenne, Wyoming-based company focused on educating and assisting companies seeking to incorporate desktop fused deposition modeling (FDM) 3D printing as part of their work process. However, he started out as a field application engineer for Pfizer’s industrial division, developing custom proprietary plastic formulations. He then launched a design and integration firm focused on custom projects for OEMs in business-to-business and business-to-consumer industries, which has been in business for 26 years. One such project in 2012 involved an OEM customer looking to get into building desktop 3D printers. Zollo was asked to develop the controller and software stack for the machine. Before he began the project, he recommended a technical audit of their machine design as well as others on the market to see if their expectations were realistic. The audit revealed 22 issues related to the quality and precision of the part produced, of which the most glaring was materials.

“Back then there were limited material choices. For example, PLA, ABS and a little bit of nylon, all of which were not exactly the materials typically used to produce precise extrusions or useful parts,” Zollo says. So, he decided to recommend new materials with better mechanical and printing performance. The customer said, “It’s only plastic; what’s the big deal?” And that was his “eureka” moment.

Material Matters

Zollo now understood that the industry was ill-equipped to make significant advancements in 3D printing due to a lack of technical understanding of plastics and how to apply material science. He also identified a gap between his customers’ engineering knowledge of part and tooling design and his company’s expertise in designing for 3D printing using FDM extrusion technology and optimizing printing strategies for high-precision parts.

“It seemed logical to start with the mechanical and chemical properties required to create high-performance parts and molds, and formulate the material to meet these requirements.”

There are thousands of experienced engineers trained in designing parts and molds using traditional, subtractive manufacturing technology, and there is a growing number of engineers with some level of experience and/or training in 3D printing parts. However, at this date, there are very few engineers who have both skill sets, and fewer yet who have relevant experience in designing, printing and using plastic 3D-printed molds, according to Zollo.

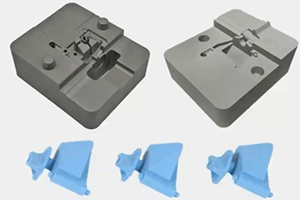

Zollo believes this lack of know-how in designing injection molds for 3D printing is the next major obstacle to broader adoption of 3D printing molds by manufacturers. Designing injection molds is all about managing plastics flow and transferring heat efficiently. Printed plastic composite molds differ from metal molds in their surface energy, mechanical strength and heat conductance, Zollo says, and these differences must be accounted for when designing the mold.

“Here’s a simple example: Increase the draft of internal pins and structures to ensure smooth movement between mold halves. If 3 percent draft was specified in the CAD drawing for metal molds, revise this to 4 to 5 percent for printed plastic molds,” Zollo says. Holes should be printed slightly smaller in diameter, so they can be postprocessed to smooth the interior.

A few other examples of principles that need to be learned and applied include how to adapt the infill and outer layer print strategy to optimize mechanical strength; how to orient the print job for optimal parting lines; how to properly dimension holes for alignment and knock-out pins; and how to properly design printed-in cooling channels.

“Engineers designing a part usually begin with mechanical and other physical characteristics and then select their material based on these requirements. For me, it seemed logical to start with the mechanical and chemical properties required to create high-performance parts and molds, and formulate the material to meet these requirements,” Zollo explains. It was then that he began to focus on developing materials for finely extruded parts. He went back to the lab and worked with a few of his previously developed materials and discovered that some of the compounds worked well for 3D printing. These high-performance composite formulations caught the attention of an automotive manufacturer that was looking to make some soft tooling. At the time, there were no injection mold-quality materials available for use on open-source FDM technology. The result of Zollo’s R&D was a carbon nanotube reinforced, high-performance composite filament for printed plastic composite molds, which he says could advance the state-of-the-art when it comes to material in injection and compression molding.

To qualify for this demanding application, the material must meet certain requirements: It must print at very low-layer heights (0.1 mm or lower). It must support common molded plastic injection, possess mechanical strength under high temperature and pressure, flex under high pressure to align to metal holding plates and alignment pins, and flex to a 100 percent seal between mold halves under pressure. It must withstand sanding, polishing, drilling, tapping and threading; have low surface energy; offer a relatively high rate of thermal transfer; adhere strongly to the print bed to ensure a precision print within desired dimensions; and exhibit very strong layer-to-layer bonding. Finally, the material must also be chemically nonreactive to the thermoplastic being molded.

“The right composite material can handle a lot of stress, but more importantly it is resilient, which is important to the molding process. It also possesses low surface energy (like Teflon), which means the injected material comes in and just glides over the surface. The carbon nanotubes act as micro bearings that make the surface tough and slick, creating a heat barrier while the material is being injected,” Zollo says. The carbon nanotubes are also excellent heat conductors within the mold that help overcome the relatively low rate of heat transfer exhibited by most plastics. Zollo explains that the proper design may include a variety of cooling channel configurations that produce good heat flow to preserve the integrity of the mold. Cooling channels can be printed as close as 2 to 3 mm from the cavity surface, creating a relatively short distance for cavity heat to travel.

“This combination of higher heat transfer rates and conformal cooling channels improves cycle time over third-party thermoset plastic molds. When designed and properly printed, there is basically no melting of the cavity surface, not even at the gates. The key is getting the heat out when it needs to get out,” Zollo explains.

Zollo’s company has teamed up with an experienced plastics molding company that has customers with short-run requirements to experiment with material science for 3D-printed molds. This technical collaboration led to his ability to create commercial-grade molded tools that have successfully run in production environments. “We are fortunate to have technical staff with experience and training in both disciplines and collaborative third parties who are helping us improve our techniques. This allows us to get the most out of the design to improve the precision, strength and finish of printed molds, as good as or better than what can be produced using more expensive industrial grade printers,” he says.

Printer Problems and Potential

Then there is the printer and the high cost of operating industrial-grade 3D printing systems for short-run injection molds. Options can cost anywhere from $100,000 to roughly $600,000. About 18 months ago, Zollo tested printing precision molds and parts on a range of open-source printers. He was not satisfied with the precision, reliability and quality of any third-party printers.

...to accommodate a range of materials, the printer must be designed to be adaptable. The delivery system should adapt to the material selected, not the other way around.

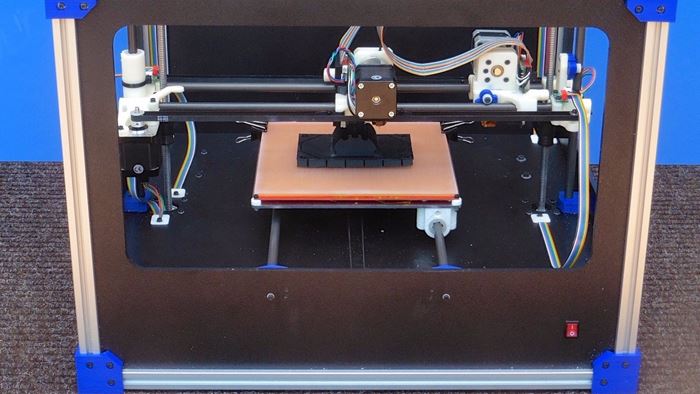

“Imprecisions are built into the typical systems that must be fixed, but companies just don’t have the money or expertise to fix these machine issues,” he says. So, he and CTO Ron Aldrich set out to develop and produce a proprietary high-precision desktop printer, which is his primary mold printing system.

“The printer is just the delivery system of the actual (real) product: the printed plastic part,” Zollo says. His approach was to develop and optimize a printer for the material being used, which is inverse to the current industry thinking. According to Zollo, his way is far more successful for printing high-performance parts. He believes that to accommodate a range of materials, the printer must be designed to be adaptable. The delivery system should adapt to the material selected, not the other way around.

“Our high-precision 3D printer looks like a conventional FDM printer, but there are several important unique features, that are not obvious, which enable printing a precision mold,” Zollo says. Unlike most conventional printers that provide print bed leveling, this printer performs a 25-point measurement of the entire print bed surface before each print job, creating a 3D profile of any deviation in flatness. This profile is used to create offsets in the print commands, automatically compensating for any imperfections in the Z axis across both X and Y axis movements of the printer nozzle. The printer uses an ARM Cortex processor-based controller board that runs an embedded real-time operating system (RTOS). This real-time operating system supports multi-threaded printing operations to optimize printing performance, which minimizes any latencies that could impact precise movement of the printer’s extruder assembly. The printer also utilizes proprietary printer driver controls of the stepper motors. Finer motor control, combined with real-time processing of G-code with automatic offsets for imperfections in the print bed results in more precise printing.

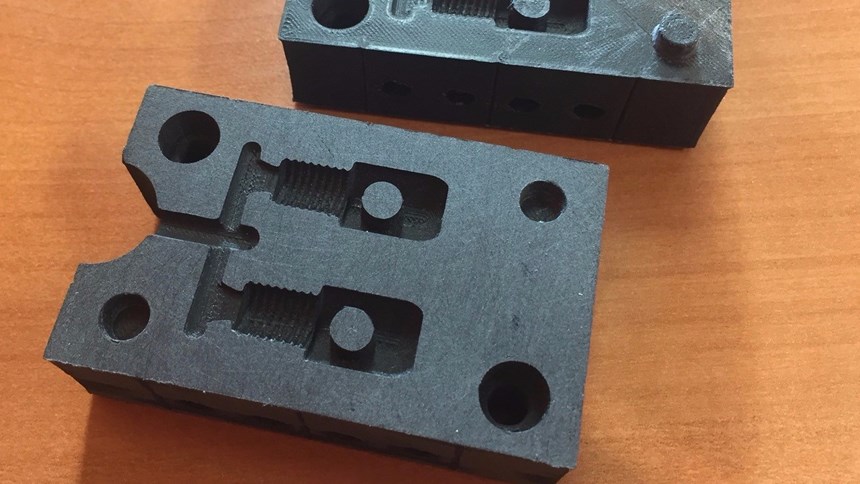

“We also have customized the STL file-slicing engine software to deliver more consistent plastic flow on the external surfaces of each printed part, resulting in a denser, smoother finish than what is typically seen with FDM printers,” Zollo says. The printer’s nozzles are optimized for printing low layer height extrusions of the company’s proprietary composite filament. The solid outer layers of the printed mold are designed with postprocessing in mind. The printed mold is sanded using conventional abrasives to 0.005-inch tolerance. The printed mold halves are quite stiff, but still exhibit a small amount of flex under pressure, Zollo explains, which allows the mold halves to close tightly to prevent flashing.

On a printed cubic inch comparison, the UV curable digital ABS used on third-party industrial printers for producing molds is fairly dense, has a relatively low rate of heat transfer and costs roughly $5.00 per printed cubic inch. Each layer of this material must be UV cured to create the thermoset and print the molds solid, which requires very long print times on expensive, industrial printing systems with long cycle times. “Depending on the in-fill printing strategy, our high-performance composite filament runs in the range of $4.00 to $7.00 per printed cubic inch on printers costing between $4,000 to $15,000,” Zollo says.

When he originally tested printing molds in his lab, he expected to be able to print small, simple molds capable of molding 10 to 20 units before wearing out. He was pleasantly surprised to learn that his printed molds could easily support 100+ cycles, depending on the design of the mold and the material being molded. While none of his clients have attempted to mold more than 125 cycles to date, inspection of the molds after this many cycles indicates no visible wear on the cavity, gates or sprues. Zollo sees no technical reason why molding parts in HDPE, ABS or PP would not hold up to 500+ cycles. He believes this compares quite favorably with molds produced on third-party printing systems. He is hearing from service providers that typical life expectancy of printed plastic molds ranges from 5 to 25 parts, depending on the plastic to be molded.

Zollo does note that there are a few practical limitations. “So far, we have focused on designing and printing simple, two-part, one- and two-cavity injection molds. The largest outer dimension printed to date is approximately 6 by 6 by 4 inches. We are working on methods to print larger molds that exhibit the desired dimensional precision, and expect to expand the range of dimensions in the near future through improved printing process control,” Zollo says.

A second limitation has to do with aesthetics. Although molds produced using his company’s composite materials are designed to be sanded and polished, it is difficult to completely remove visibility of the print lines in the surface of the molded part. He continues to research new methods to improve surface finish. For parts that have an aesthetic requirement, he recommends embossing the surface with a pattern, either in the print design or via postprocessing.

Gaining Ground

To widen the field of compatible printers for users, Zollo’s company tested and validated precision printing of the high-performance composite filament on a number of new open-source printers. To date, he determined that European-based German RepRap, the Italian printer maker Roboze and the American manufacturer Airwolf produce printer models with the required precision to support printing molds using his composite filament, which range in size, features and price from $4,000 to $25,000.

These printers have improved bed leveling and print head calibration capabilities, offer enclosed chambers for improved control over temperatures, exhibit precision control of the extruder assemblies, offer even heating of their print beds and some feature belt-less robotic control for the most precise control over extruder movement. “A lack of any of these capabilities makes it difficult to print a quality injection mold,” Zollo says.

He says he continues to test new third-party, industrial-grade printers as they become available. He strongly believes the industry needs to have options and the power to select the appropriate printing system for their application. His focus is on two key markets: manufacturers seeking pilot production and/or low-cost, quick-turn, short-run molded plastic part production.

“We quickly learned that this is a conservative industry, as manufacturing engineers asked for technical validation before investing, even at our extremely low pricing. It was a logical next step to offer full-service from design to mold delivery to reduce the technical risk and speed up the assessment process for the client manufacturer,” Zollo explains.

His company can take the customer’s CAD file and STL files for the part and/or mold and redesign them, or start from the customer’s part design and implement the entire design and build process. Once a customer is confident in his approach, they have the option of buying the high-performance composite filament and printing their own molds if they have a printer with adequate precision. If they need to upgrade their 3D printer, Zollo can offer the customer a range of printers from his own high-precision desktop printer for small jobs, or the range of German RepRap printers for larger printing projects. For the highest precision, Zollo recommends the Roboze line of industrial-grade FDM printers.

This integrated solution, which provides a service supported with the right technical background and technology, builds a bridge to AM for those looking for economical mold solutions.

Related Content

Make Every Shot Count: Mold Simulation Maximizes Functional Parts From Printed Tooling

If a printed tool only has a finite number of shots in it, why waste any of them on process development?

Read More8 Ways the Plastics Industry Is Using 3D Printing

Plastics processors are finding applications for 3D printing around the plant and across the supply chain. Here are 8 examples.

Read MoreMantle: 3D Printed Molds Address Plastics Industry Lead Time and Skills Shortage

Company now shipping production systems. Steel mold tooling from its TrueShape process can be printed, shaped and sintered in days, and with fewer steps, compared to weeks of lead time for molds made conventionally.

Read MoreNicolet Plastics Succeeds Using Mantle's Hybrid Metal 3D Printing Method for Mold Tooling

A recent webinar explores Nicolet Plastics’ success using Trueshape Technology, Mantle’s approach to print injection mold tooling. The current challenges this technology addresses and alleviates in additive manufacturing confirms this method is effectively reducing lead times and cost constraints, while producing better inserts.

Read MoreRead Next

How Avid Product Development Creates Efficiencies in High-Mix, Low-Volume Additive Manufacturing

Contract manufacturer Avid Product Development (a Lubrizol company) has developed strategies to streamline part production through 3D printing so its engineering team can focus on development, design, assembly and other services.

Read MorePostprocessing Steps and Costs for Metal 3D Printing

When your metal part is done 3D printing, you just pull it out of the machine and start using it, right? Not exactly.

Read MoreNew Equipment, Additive Manufacturing for Casting Replacement and AM's Next Phase at IMTS 2024: AM Radio #54

Additive manufacturing’s presence at IMTS – The International Manufacturing Technology Show revealed trends in technology as well as how 3D printing is being applied today and where it will be tomorrow. Peter Zelinski and I share observations from the show on this episode of AM Radio.

Read More