Material Extrusion: Now with Metal

Challenging our thinking about materials in metal additive manufacturing and the possibilities with material extrusion technology.

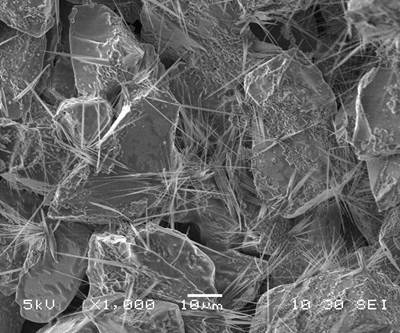

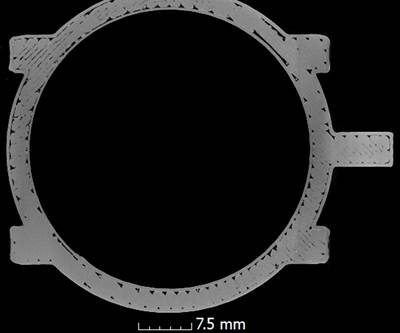

Replica of Vortic Watch Co.’s watch case printed in 17-4PH Stainless Steel on Desktop Metal (left) and MarkForged (right) material extrusion systems.

Additive manufacturing (AM) is impacting a lot of industries, but one of the biggest complaints that I hear, particularly from aerospace companies where lightweighting is key, is the inability to use traditional 6000- and 7000-series aluminum alloys when additively manufacturing parts, particularly via powder-bed fusion (PBF). These alloys are difficult to weld, and not surprisingly, they are just as susceptible to cracking when melting and fusing aluminum powder particles with a laser during powder-bed fusion (or when using directed energy deposition (DED)). This is why AlSi10Mg is used on most powder-bed fusion systems. It is a grade of aluminum that is not as susceptible to cracking; however, it does not have the same strength as 6000- and 7000-series aluminum, which is the “go-to” material for many companies trying to lightweight components.

When a company is considering switching to a new manufacturing process (e.g., subtractive to additive), its first inclination is to use the same material and just process it differently. Now you see the dilemma: if AM can’t process the same material, then you can’t justify the change for that component. As a result, when companies review parts to find candidates for fabrication with AM, none of the 6000- or 7000-series aluminum parts pass the filter. But what if a part didn’t have to be aluminum?

This is where our traditional mindset is limiting us. Many companies turn to aluminum because it is inexpensive and easy to machine. As a result, it is often a “no brainer” to hog a part out of a big block of aluminum, no matter how much scrap is produced. But what if we could process other strong materials easily? Moreover, what if scrap was reduced — or better yet, eliminated — during processing? That is the thinking that AM enables, and that is where material extrusion is finding new excitement.

What if we could process other strong materials easily? Moreover, what if scrap was reduced — or better yet, eliminated — during processing? That is the thinking that AM enables, and that is where material extrusion is finding new excitement.

As we discussed last month, material extrusion makes it easy to fabricate plastic components from traditional polymers (ABS, polycarbonate, etc.), and parts made with FAA-certified polymers like ULTEM 9805 have been flying on aircraft for years. Recent advancements in processing technology now enable high-temperature/high-strength/chemically resistant polymers like PEEK and PAEK to be additively manufactured with material extrusion. Given their recent introduction to the market, the parts made with materials lag what can be accomplished with selective laser sintering (a laser-based powder bed fusion technology), but more and more applications are within reach thanks to these advances.

Meanwhile, companies like MarkForged have found ways to add chopped and continuous fiber to parts made on their material extrusion systems. This composite reinforcement leads to much stronger components from material extrusion, and it is systems like these that are challenging people’s assumptions about materials. For instance, if I could print an enclosure, frame, box or lid out of composite-reinforced polymer instead of machining it out of aluminum, then why not? Material extrusion with composite-reinforced polymers becomes a compelling option if I can print what I need, when I need it, in any size I want and also reduce scrap, use less material, and have it be just as strong. Granted, it may take awhile to convince someone that a composite material is just as strong as its aluminum equivalent, but look no further than Boeing’s 787 Dreamliner to see how strong, lightweight materials win out over time once the associated manufacturing process is well understood.

If composite-reinforced polymers will not win over your customers, then keep a close eye on the metal parts being made with material extrusion systems. This where all the excitement (and the investment) is these days as companies like MarkForged and Desktop Metal offer material extrusion systems that print metal parts. In both cases, the polymer filament, impregnated with small metallic particles, is deposited layer-by-layer just like any other material extrusion process. Stainless steel, specifically, 17-4PH, is the “go-to market metal” for both companies, but lots of metal alloys are being released or are in development such as 316L, H13 and other tool steels along with copper, titanium, nickel-based superalloys and, of course, aluminum.

The trick in each case is figuring out the thermal postprocessing as the “green” part is heated in an oven to debind and sinter the material, essentially melting away the plastic and leaving the metal behind. This is an extra step that is not required for plastic parts, and it may catch some people off guard, but the end result is different – a metal part made by material extrusion (see images). Granted, metal parts made with material extrusion are not as dense as you would achieve with laser powder-bed fusion (manufacturers report 96%-98% density vs. 99.5-99.9% in respective material data sheets), but they are certainly solid and strong enough for tooling, fixturing, and similar applications. Meanwhile, process improvements are leading to thinner layers and tighter track spacing, which leads to fewer voids, higher density and better strength. It will likely be awhile before we make flight critical components in metal with material extrusion, but in the meantime, the new range of materials that can be easily processed with material extrusion, including metals, are creating exciting new possibilities for this decades old AM technology.

Related Content

For Coast Guard, AM Adoption Begins With “MacGyver-ish” Crew Members Who Are Using 3D Printing Already

AM suits the Coast Guard’s culture of shipboard problem-solving, says Surface Fleet AM lead. Here is how 3D printers on ships promise to deliver not just substantial cost savings but also an aid to crew capabilities and morale.

Read MoreMaterialise Adopts New Materials to Expand its Manufacturing Service Offerings

By expanding its manufacturing service offerings with PA 11, PA 12S and PA-CF materials, Materialise aims to meet the evolving needs of its customers.

Read MoreRaise3D’s Hyper Core Filament Line Offers Increased Heat Conductivity for Rapid Melting and Cooling

Raise3D has also launched its Pro3 HS Series which enables higher speed printing with composite materials to meet demanding engineering and manufacturing needs. The series includes the Pro3 HS, Pro3 HS Plus, Pro3 + HUK3 and Pro3 Plus + HUK3.

Read MoreNIOSH Publishes 3D Printing Safety Guide for Nonindustrial Settings

NIOSH has published a 3D printing safety guide for small businesses and other additive manufacturing users such as makerspace users, schools, libraries and small businesses.

Read MoreRead Next

Are Crystals the Key to 3D Printing with Silicon Carbide?

If SiC was easier and cheaper to apply, we would find many more uses for this hard, lightweight ceramic. Researchers have found a promising additive manufacturing approach, with crystal growth as the bonding mechanism.

Read MoreUltem, PEEK or PEKK? Choosing Between High-Temperature Plastics

How do you choose between these high-performance materials? A conversation with Arkema and Plural AM sheds light on 3D printing with these polymers.

Read MoreAdditive Manufacturing Via Material Extrusion

Material extrusion was the second additive manufacturing process to be successfully commercialized. After three decades of material advancements and a diverse array of start-ups and applications, the use cases for this technology are still going strong.

Read More