Is Recycled Metal Scrap the Future Feedstock of Choice for Metal 3D Printing?

MolyWorks is future-proofing the circular economy for metals with small-footprint atomization technology that converts metal scrap into additive manufacturing powder on the spot. But that's not the end of the story.

One promise of additive manufacturing (AM) is the potential for distributed manufacturing. When designs live as digital files in the cloud, and a batch of powder contains the potential to 3D print any of them, it becomes possible to manufacture a part or product exactly where and when it is needed. A distributed manufacturing model reduces shipping, removes the need for inventory, and promises faster, more flexible delivery of goods.

What if similar benefits could be achieved at the end of a product’s life, with a distributed recycling model?

That’s part of the inspiration behind MolyWorks, a California-based company that hopes to reduce reliance on virgin metals by recycling existing material closer to its source and users. The company has developed a process for melting and atomizing scrap metal into powder suitable for additive manufacturing within a footprint smaller than the average conference room. In theory, these small recycling facilities could be distributed all across the globe, placed in manufacturing regions or even held captive by individual OEMs to give existing metal new life as 3D printing stock.

AM Powder: The Best Use of Recycled Metal

Recycling metal scrap into AM-grade powder is a challenging task, but one that is worthwhile from both an environmental and business standpoint. “Every time something is thrown away or can’t be recycled at a high efficiency, we’re wasting our natural capital and mining more than we really need to,” says Chris Eonta, co-founder and CEO. Recycling that scrap into feedstock preserves natural resources — compared to mining virgin material, recycling metals has lower energy requirements and causes less air and water pollution.

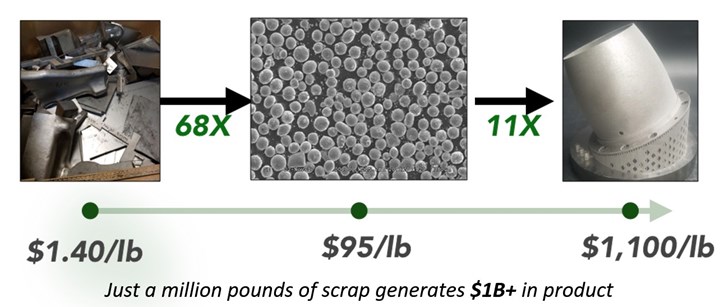

But turning scrap into powder for 3D printing, specifically, raises the material’s value while preparing it for a versatile process that resists future material waste. “With raw product like ingot, you’re limited to the things you can produce and there is still inherent waste,” Eonta says. “Powder is the most versatile feedstock. You can print anything that fits inside the printer.”

Why AM powder and not some other feedstock? Metal 3D printing powders are among the most lucrative and versatile feedstocks. And, they are uniform and easier to ship than scrap or parts. Photo Credit: Molyworks

The Small-Footprint Foundry

To efficiently convert scrap into powder, MolyWorks uses a combination of arc-based melting with “horizontal free fall” atomization, a process that drops the molten metal through a horizontal stream of gas to create tiny spherical grains of powder. The process is fast, efficient and so far has been found to be alloy-agnostic. All the necessary equipment fits inside a compact, reasonably mobile package as a result of where it was developed: a shipping container on the now-CTO’s front lawn.

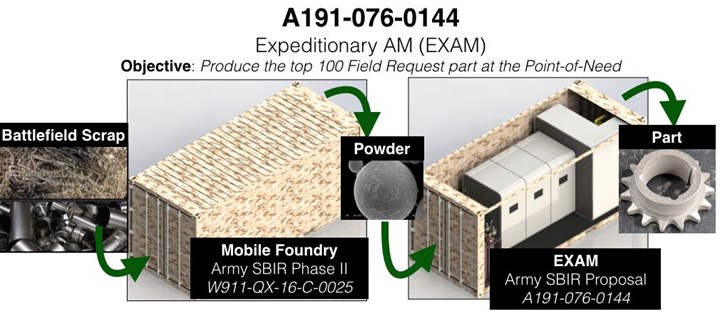

“We planned to rent a diesel generator when we were ready to test it, then pursue a larger investment and move seamlessly into a facility,” Eonta says. The technology never shed that compact footprint, however, thanks to an Army solicitation that came about 6 months after its work had begun. The call was for almost precisely what MolyWorks was developing: a system that could be shipped to a battlefield, operate on about 180 kilowatts of power, and take indigenous or battlefield scrap and convert it into powder for metal 3D printing.

MolyWorks didn’t intend that its systems would be portable, but the accident that the technology was developed in a shipping container subsequently made it perfect as a “Mobile Foundry.”

MolyWorks won Small Business Innovation Research (SBIR) funding for its “Mobile Foundry” proposal, and is now in extended phase two with the program. This project has been a catalyst for advancing MolyWorks’ melting and atomization technology by providing real-world test cases. “We’ve melted tank track. We’ve melted lunch cans. We’ve melted a field scope, engine blocks, rolled homogenous armor…all kinds of real-life battlefield pieces,” Eonta says.

Subsequent SBIR projects have allowed the company to prove out the printability of its recycled material, by turning titanium forging scrap into nonstructural parts for Air Force landing gear, for example. Commercially, the company is now offering custom alloys as well as recycling and metal 3D printing services.

Know the Input

Creating usable AM powder from recycled metal isn’t as simple as collecting and processing scrap. Additive manufacturing-grade powder must meet exacting standards in terms of both its physical characteristics (sphericity, flowability, etc.) and its chemical makeup. It’s important, therefore, to know both the type of alloy and the precise chemistry present in the source scrap material.

Generally speaking, recycling metal tends to be more energy efficient than mining and processing new ore, but the yield from recycling a given material can vary. MolyWorks has a heavy focus on titanium, for instance, because it makes up about 30% of the global AM market and is also one of the most efficient elements to recycle. The metal is resistant to corrosion and rust in use, which means the material is purer when reclaimed, and requires a high-vacuum melting atmosphere during recycling that prevents contamination as a side effect. This means that about 90% of a batch of titanium scrap can be reclaimed; other metals like steel and aluminum are closer to 60% efficient, Eonta says.

Sorting is the first step in the recycling process, followed by chemical analysis to determine the material’s levels of hydrogen, nitrogen and oxygen, which are considered contaminants. MolyWorks might mix different batches of scrap or introduce virgin material to obtain the desired combination in the finished powder. In some cases, even parts of the same object can be mixed together to achieve the right chemistry.

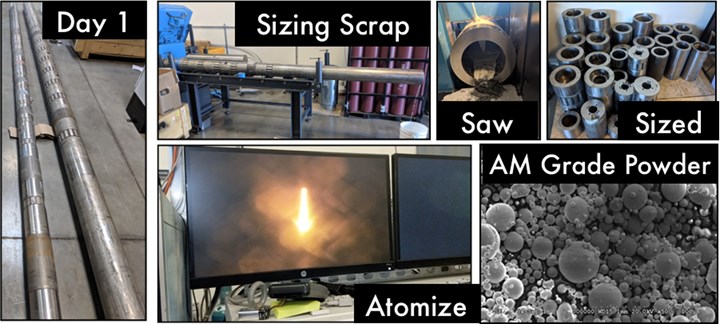

“In one case we processed a 20-foot-long oilfield drill collar that we had to size down with a bandsaw,” Eonta says. “We then took samples of each section using a handheld XRF, and used our in-house analyzer to judge the oxygen contamination. We used that oxygen content to blend the different sections of the drill collar to get the final spec right.”

This slide from MolyWorks shows glimpses of the process for recycling the drill collar into AM-grade metal powder.

Schlumberger used the material reclaimed from the drill collar to 3D print the downhole drilling parts (left) and hydraulic manifold pictured. Ideally, MolyWorks sees closed-loop applications like this occurring near the oilfield or other point of use.

Eonta recognizes that starting with scrap can be a concern for potential buyers and users of this powder. At the moment, this analysis and subsequent blending is the best way to know the material’s starting conditions and ensure a useable product. But he anticipates that this won’t always be the case, and in fact recycled metal scrap could one day be the feedstock of choice. As a future-proofing measure, the company prints a QR code into every part that it manufactures, linking the item to a record in its Molyware tracking system.

“That part can go out into service and if it gets sent back to us, we know exactly what it was made from,” Eonta says. “Parts coming home are then fully traceable, so it actually becomes a more advantageous feedstock than previously thought.”

If a MolyWorks-made part returns to the company in the future for recycling, its starting material blend will already be known thanks to a printed QR code like this. Photo Credit: MolyWorks

A Recycling Facility in Every Region

At present MolyWorks is focused on powder production and 3D printing services, but the main commercial promise it sees is in recycling as a service. For a fee, customers can send their scrap to be recycled and returned to them as powder. Currently MolyWorks processes this material from its facility in Cloverdale, California, but the service business is a way to assess the potential for recycling closer to customers.

“Once we’ve established those scrap sources, we can think about placing one of our systems at or near that facility to consume scrap in the region,” Eonta says. A distributed network like this would help to incentivize companies to recycle their scrap, and potentially reduce the cost of metal AM powder for the surrounding region.

The right operator for these systems is unclear at the moment, but one potential answer is OEMs themselves. Aerospace and defense manufacturers, for instance, often must provide certificates of material destruction to prove that used or defective parts won’t find their way back onto aircraft or into undesirable hands.

“With our system, scrap can be processed on site so that no one else ever sees those parts,” Eonta says. Companies can create new feedstock while protecting their IP at the same time. But the greater reason to bring recycling to scrap producers and powder users is to make the recycling process truly efficient and worthwhile in the long run.

“Wherever the scrap metal is, that’s where you need to be able to convert it into a product again.”

“If you look at the four quadrants of the circular economy, the fourth one—collection, sorting, reprocessing—is the most difficult part,” Eonta says. “People are willing to send the scrap once or twice, but then they don’t. You need the distributed network, where the scrap collecting and recycling is near that manufacturing site. Wherever the scrap metal is, that’s where you need to be able to convert it into a product again, whether powder or printed part.”

Related Content

Evaluating the Printability and Mechanical Properties of LFAM Regrind

A study conducted by SABIC and Local Motors identified potential for the reuse of scrap reinforced polymer from large-format additive manufacturing. As this method increases in popularity, sustainable practices for recycling excess materials is a burgeoning concern.

Read MoreCopper, New Metal Printing Processes, Upgrades Based on Software and More from Formnext 2023: AM Radio #46

Formnext 2023 showed that additive manufacturing may be maturing, but it is certainly not stagnant. In this episode, we dive into observations around technology enhancements, new processes and materials, robots, sustainability and more trends from the show.

Read More3D Printing Brings Sustainability, Accessibility to Glass Manufacturing

Australian startup Maple Glass Printing has developed a process for extruding glass into artwork, lab implements and architectural elements. Along the way, the company has also found more efficient ways of recycling this material.

Read MoreVideo: A Mechanical Method for Metal Powder Production

Metal Powder Works has developed a method for producing powders from solid barstock, no melting required. This video covers how the process works and benefits of mechanical production of powders.

Read MoreRead Next

How a Solid-State Process Stood Firm Until Additive’s Moment

Early on, this company saw the promise of friction stir welding for building forms in layers. Few understood at the time. They understand now, in part because this process offers benefits such as blended materials and freedom from stress that other metal AM approaches can’t match.

Read MoreAdditive Manufacturing Will Aid And Accelerate The Circular Economy

A circular economy links material, design, manufacturing, product and end-of-life in a continuous, sustainable loop. This special report illustrates the roles for 3D printing every step of the way.

Read MoreMetal 3D Printing in a Machine Shop? Ask the Marines

A hybrid system combining metal 3D printing with machining gives the Marine Corps perhaps its most effective resource yet for obtaining needed hardware in the field. It also offers an extreme version of the experience a machine shop might have in adding metal AM to its capabilities.

Read More

.jpg;width=70;height=70;mode=crop)