AM 101: Multi Jet Fusion (MJF)

From functional prototypes to end-use parts, HP’s Multi Jet Fusion (MJF) is capable of efficient production. Learn about MJF, including its materials, postprocessing requirements, benefits and more, in this 101 post.

What Is Multi Jet Fusion (MJF)?

Multi Jet Fusion (MJF) is a powder-bed 3D printing process developed by HP that bonds agent and powder in a process similar to binder jetting. Unlike point-by-point laser-based powder-bed fusion systems, MJF selectively distributes fusing and detailing agents across a bed of powder, and layers are fused together using infrared light.

The Multi Jet Fusion system consists of exchangeable build units that can be wheeled between MJF 3D printers and separate postprocessing stations for rapid cooldown and powder removal. This modular system enables the printer and postprocessing stations to run continuously while build units cycle through, speeding part production.

How Does Multi Jet Fusion Work?

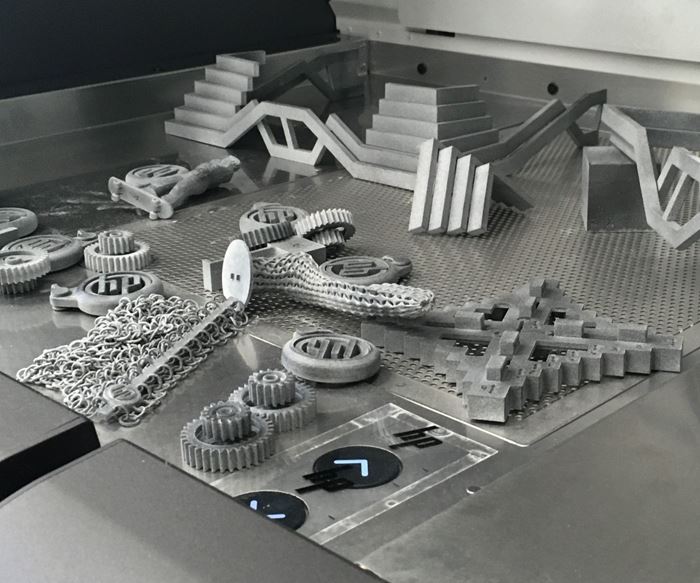

The Multi Jet Fusion printhead deposits droplets of binding and detailing agents across layers of polymer powder in a preheated bed. The binder serves as a heat-absorbing ink, making the powder it binds more prone to melting. Each layer is fused using infrared light to melt the areas held by the binding agent all at once. Meanwhile, the detailing agent enables a cooling effect, providing crisp edges around the melted area and preventing the meltpool from bleeding into the loose powder. Powder is distributed on top of each solid layer, and the process repeats until the part is complete. The powder supports the parts as they grow; support structures are not necessary, which enables greater design freedom and enables larger quantities to be produced at once.

What Postprocessing Is Required?

When the build finishes, the build unit (the entire powder bed with the encapsulated parts) is removed from the printer and placed into the postprocessing unit for rapid cooling. Then the build unit is moved to a processing station where loose powder is removed by vacuum.

Final parts are said to have quality surface finishes, fine feature resolution and more consistent mechanical properties when compared to laser-based powder bed processes like selective laser sintering (SLS). And, because heating takes place layer by layer with powder packed beneath the parts, warping occurs less with MJF than with SLS.

To improve surface finish, parts can be bead blasted, then given a primer finish or a paint finish. Printed parts can be dyed or treated further if required for the application.

What Materials Can Be Used?

Multi Jet Fusion is compatible with a selection of thermoplastics from HP, including High Reusability (HR) PA 12 nylon, HR PA 12 GB (a nylon reinforced with glass beads) and HR PA 11.

HP also supports a 3D Materials Certification Program and has partnered with polymer 3D printing material suppliers to develop new materials. Material partners include Arkema, BASF, Dressler Group, Evonik, Henkel, Lehmann & Voss & Co., Lubrizol and Sigma Design.

Why Use Multi Jet Fusion?

Multi Jet Fusion can produce functional prototypes and end-use production parts in as fast as one day. A single MJF printer has the ability to run almost continuously if the build units are swapped out for postprocessing as each print is completed. Used powder can be recycled by loading it back into a build unit from the postprocessing station.

The layer-by-layer fusion of MJF enables the process to be faster than point-by-point 3D printing systems, and each layer is said to take the same amount of time to fuse regardless of complexity. With MJF it is possible to nest parts vertically as well as horizontally, filling the entire build volume with individual, separate parts. Multi Jet Fusion requires no tooling investment or minimum order volume; these factors combined with its speed make the process competitive with injection molding for serial production.

Related Content

Seurat: Speed Is How AM Competes Against Machining, Casting, Forging

“We don’t ask for DFAM first,” says CEO. A new Boston-area additive manufacturing factory will deliver high-volume metal part production at unit costs beating conventional processes.

Read More3D Printed Cutting Tool for Large Transmission Part: The Cool Parts Show Bonus

A boring tool that was once 30 kg challenged the performance of the machining center using it. The replacement tool is 11.5 kg, and more efficient as well, thanks to generative design.

Read MoreNew Zeda Additive Manufacturing Factory in Ohio Will Serve Medical, Military and Aerospace Production

Site providing laser powder bed fusion as well as machining and other postprocessing will open in late 2023, and will employ over 100. Chief technology officer Greg Morris sees economic and personnel advantages of serving different markets from a single AM facility.

Read MoreTop 10 Additive Manufacturing Stories of 2023

Laser powder bed fusion, proprietary AM processes, machining and more made our list of top 10 articles and videos by pageviews this year.

Read MoreRead Next

HP Partners with Deloitte to Bring Additive Manufacturing to the Enterprise Level

HP’s Multi Jet Fusion process is being used as a production technology today, but now the company has its sights set on enterprise-level (and industry-wide) disruption enabled by partnerships and spanning the entire supply chain.

Read MoreHow Forecast 3D Is Taking 3D Printing into Mass Production

Forecast 3D got its start building silicone molds from 3D-printed master patterns. Now, through the use of Multi Jet Fusion, the company sees a future in manufacturing large quantities of 3D-printed parts.

Read MoreNiche Manufacturer Discovers How Additive and Amazon Go Together

The economics of 3D printing allow for cost-effective production of niche products, and Amazon Prime offers a way to distribute them. The Periscope Case is one company’s first venture into an all-new model aimed at bringing products to market that would never have been profitable before.

Read More