Additive manufacturing (AM) is well understood as a design enabler. It allows for design options and design modifications that would be impractical to realize with any other manufacturing method. But AM is potentially just as promising as a marketing enabler, offering consumer product makers a go-to-market strategy that couldn’t be cost-effective any other way.

At least, that is the promise Trevor deVos sees. His Oregon-based startup is Defox LLC. This company’s first product is the Periscope Case, an aid to remote filming with a smartphone. The case is (fittingly) a test case. Not only is it a niche product manufactured via 3D printing, it’s also the pioneer product in a new model for profitably marketing other items with niche appeal.

And deVos says it all began with fear of spiders.

Phones Meet Drones

The Periscope Case is a cellphone case able to hold a mirror at a precise 45-degree angle so the camera sees a perpendicular view, like a periscope. The case therefore allows the phone to lay flat, or to be mounted flat onto another object, and film in the direction of its length. Thus the phone can operate like a remote wireless camera. “Like a poor man’s GoPro,” deVos says.

“I got the idea because I needed to get into the crawlspace of my house,” he explains. “It was full of spiders. No way was I going in. So I duct-taped an old phone to a radio-control car and I livestreamed the phone’s video to Facebook so I could watch remotely. The most difficult part was holding a mirror at an angle so the phone would film in the right direction. I used clay to hold it, and getting it just right was a challenge.” He thought there ought to be a special cellphone case built to meet this challenge..

Voila, the Periscope Case. The product he developed out of his crawlspace experience aims to serve potential users including do-it-yourselfers requiring hard-to-access views like the one he confronted, sports and outdoor enthusiasts (who might mount the case on bike handlebars, for example), or parents enjoying it as a way to get quick candid shots of children who otherwise won’t pause for photos. One recent order came from a group of teens building battle drones who now use Periscope Cases to mount their outdated phones to their creations.

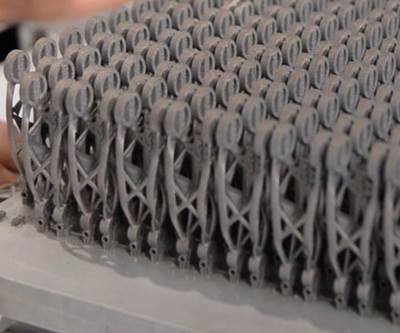

The case is manufactured for Defox on HP’s Multi Jet Fusion 3D printing platform by RapidMade of Tigard, Oregon. RapidMade was one of the earliest users of the HP platform. Manufacturing was the fundamental challenge for this product, deVos says, because distribution and marketing were the biggest challenges of all. For a product such as this—targeted to Amazon Prime—the method of manufacturing is a key enabler to realizing this hoped-for method of distribution.

Prime Ambition

He says, “To get the case on Prime was our goal from the beginning.” Distribution by Amazon is, perhaps obviously, the best course for reaching the product’s widely dispersed potential users. The goal was achieved; the case is now an Amazon Prime product. But pursuing that goal raised questions that were directly manufacturing-related, he says. Those questions included, “Can we get the cost down low enough?” and “Can we get the quality consistent enough?” Ultimately, the course Defox charted is one it hopes to follow for other promising products—the course through AM and onto Amazon.

Additive manufacturing was essential for bringing the case to market because the product would otherwise require mold tooling. Given the limits of the case’s potential market, there was no safe way to proceed to market where this initial investment was required. Potential buyers might be few and the early design might not be final. The right way to market this product, and the only reasonable way deVos saw, was to begin with an initial quantity of around 50, see how sales go, and see if the responses from initial users uncover the need for any design changes. Only AM could allow for a cost-effective initial production run of a plastic product at such a low quantity.

HP’s Multi Jet Fusion is a polymer 3D printing system designed for batch production. DeVos says testing with an off-the-shelf nylon for this machine revealed the material was durable enough to serve as a phone case. Drop tests from hip height proved the material protected the phone just fine.

The questions then came down to cost.

AM Economics

He says, “The price of 3D printing is driven by time in the machine.” Material cost is not a large factor in comparison. And time in the machine is a design function, he notes, because the envelope needed for 3D printing is driven by part geometry. Working with design partner Open Fab PDX, a specialist in design for AM, deVos ended up redesigning the case to make additive manufacturing cheaper.

“An early version had a hinge for the mirror that protruded from the profile,” he says. The protrusion enlarged the envelope a batch of cases would require in the machine—adding printing layers, adding time. The redesign replaced this hinge with an alternate (snap-on) approach to mounting the mirror. The resulting geometry change reduced the height of the 3D printing envelope by ¾ inch, measurably reducing cost. The change also offered a side benefit: “The case now slips in the pocket more easily,” he says.

Some things don’t change. Even with 3D printing, cost savings still result from quantity. Crucially, though, the quantity breaks for AM come at much lower numbers than conventional manufacturing.

“RapidMade can give us price breaks at order sizes of 10, 50 and 100,” deVos notes. He stuck to the first break early on, ordering in quantities of 10 to 25 so he could keep on making small design changes based on user experience. This points to another AM advantage that molding cannot deliver: the freedom to make ongoing design tweaks even after the product has entered production. For a niche manufacturer, there is no other way to finalize the product. The only way to do market research is to go to market.

The case becomes profitable for Defox at an order quantity of 100. “And a quantity of 500 fills the machine, so price bottoms out,” deVos says. “We want to get to this.”

He likely will get to this quantity—not just with the Periscope Case, but perhaps with many other items as well. Indeed, having multiple product lines manufactured this way will make it easier to achieve low-cost production for all of them, because Defox can potentially fill the machine with batches of separate products nested together within the same build. DeVos’s next step is to seek partnerships—opportunities to apply lessons learned from the Periscope Case to other inventors’ niche products.

“We are not looking for ideas that will change the world,” he says. Still, his company is pioneering something potentially world-changing for those ideas: a manufacturing and marketing model able to advance tiny ideas rather than big ones.

See the Periscope case in action in this video.

Related Content

Why AM Leads to Internal Production for Collins Aerospace (Includes Video)

A new Charlotte-area center will provide additive manufacturing expertise and production capacity for Collins business units based across the country, allowing the company to guard proprietary design and process details that are often part of AM.

Read MoreThis Drone Bird with 3D Printed Parts Mimics a Peregrine Falcon: The Cool Parts Show #66

The Drone Bird Company has developed aircraft that mimic birds of prey to scare off problem birds. The drones feature 3D printed fuselages made by Parts on Demand from ALM materials.

Read MoreVulcanForms Is Forging a New Model for Large-Scale Production (and It's More Than 3D Printing)

The MIT spinout leverages proprietary high-power laser powder bed fusion alongside machining in the context of digitized, cost-effective and “maniacally focused” production.

Read MoreVideo: 5" Diameter Navy Artillery Rounds Made Through Robot Directed Energy Deposition (DED) Instead of Forging

Big Metal Additive conceives additive manufacturing production factory making hundreds of Navy projectile housings per day.

Read MoreRead Next

Video: 3D Printing Is a Complement and Competitor to Injection Molding

Ken Burns of Forecast 3D, an early adopter of HP Multi Jet Fusion, sees 3D printing as both a complement and a competitor to injection molding. He shares why in this interview.

Read MoreVideo: Periscope Case Shows 3D Printing for Niche Manufacturing

Manufacturing without mold tooling allows the production quantity to be tailored to the market size.

Read MoreAdditive Manufacturing Is Succeeding in Production! Here Are Examples

We are no longer predicting that additive manufacturing will be used in production — because it already is. Find real stories of 3D printing for full production at AM's leading edge in this collection.

Read More