3D Printing and Coronavirus Check-In - Week of 3/23/2020

Editors Peter Zelinski and Stephanie Hendrixson discuss 3D printing issues related to ventilators, personal protective equipment (PPE) such as masks and face shields, and how business conditions have been affected by coronavirus.

Additive Manufacturing’s editors have been working hard to report as quickly and accurately as we can on how the coronavirus pandemic is affecting manufacturing — both in the 3D printing sense, and manufacturing more broadly.

This video is the first of what we intend to be an ongoing series about the intersection of COVID-19 and AM. In each installment, we’ll discuss new developments and try to put them into context for viewers. In this first video, we cover 3D printing efforts to manufacture ventilator parts, respirators and face shields; coordinated projects by 3D printing suppliers and other organizations to assist the healthcare industry; and COVID-19’s impact on business conditions for additive manufacturers.

Transcript

Peter Zelinski

Peter Zelinski with Additive Manufacturing dot Media.

Stephanie Hendrixson

I'm Stephanie Hendrixson, with Additive Manufacturing dot Media.

Peter Zelinski

And we're trying something new here. So within the coronavirus crisis, there's a manufacturing aspect of the story there. There are many manufacturing aspects of the story. A lot of it has to do with 3D printing, a lot of it has to do with additive manufacturing. And it's all happening fast coming quickly. And so what we decided to do is, we're going to film occasional videos just to kind of talk it out quickly touch on some of the manufacturing related news. A lot of it is additive manufacturing related, not exclusively additive, but so much of what's happening in this space, we thought Additive Manufacturing Media is the right place to talk about it. So we think maybe roughly once a week, we're gonna post videos like this. Does that sound right to you? Stephanie?

Stephanie Hendrixson

Yeah, and so I think the format that these are going to take is will take is we’ll identify a couple of different big topics or big stories that we want to address in each week. And to get us started today, I think the first thing that we're going to talk about is ventilators. This is something that we've been hearing a lot about, especially like 3D printing components of ventilators.

And just kind of as a base level starting point, a ventilator is a mechanical device that helps put air into a patient's lungs. The coronavirus has an effect on the respiratory system, so these are really, really important devices. So Pete, you posted a blog post to our site recently about ventilators. Talk about that.

Peter Zelinski

Yeah. So so so ventilators are maybe the most urgently needed piece of manufactured piece of medical equipment in this crisis, the the potential lack of ventilators. There's a shortfall by an order of magnitude. I think I just heard today that in in New York alone, something like there's a need for 40,000 more ventilators.

Manufacturing—it's worth saying that the manufacturing part of this story is the reason why we're all sitting at home right now. Trying to figure out how to ramp up production and how to meet the potential shortfall of some of this desperately needed medical equipment is why we're all sitting at sitting this out avoiding each other trying to slow down the spread of this of this virus, just to provide more time for the production ramp up that has to come and and the challenges are significant. A ventilator is an example of a piece of equipment sophisticated enough that there's not a really great crowdsource solution for how to meet this.

So, automakers are getting involved. We're hearing news of General Motors, working with a ventilator supplier to try to figure out how to devote its manufacturing resources to help scale up production. VW is committing to using 3D printing to try to get involved here and scale up production. But really, we haven't heard a lot of information yet about real concrete successes that are coming with ventilator production. You get the sense that these big medical device makers and large manufacturers like the automakers, I think right now they're probably they, they very likely are still in the stage of wrapping their heads around this problem. It is very difficult to retool and existing manufacturing line devoted to some other purpose in the making ventilators.

In the meantime, here are some other things I'm hearing about and it gives us a picture of the kind of the the seriousness of the situation. So there are hospitals who are commissioning contract manufacturers, 3D printing service providers to make devices for splitting the tubing to allow multiple patients to share the same, the same ventilator. This is very controversial. There's, there's there's a real debate about whether this is even an effective or appropriate solution. This is not FDA approved. But nevertheless, hospitals seeing a potential crisis in their shortfall of ventilator capacity, are looking for solutions like this looking for ways to kind of work around the rules and and devote multiple patients per ventilator. I guess.

So what what, what anecdotes like that show are just how desperate the ventilator problem is, in particular, and how valuable these measures are. Everything we can do to slow down the spread of this virus, provide more weeks, more months, potentially bring More ventilators into service and reduces the suffering that might result from this illness.

Stephanie Hendrixson

Yeah, so you bring up a couple of really good points there. So this whole idea of crowdsourcing and looking to 3D printing as a solution, I feel like there's some misinformation floating around. Like there's there's the one success story that we've seen with ventilator valves was a story out of Italy, where there were a couple of different 3D printing companies that kind of came into a hospital and were able to print some valves on very short notice to keep the ventilators running. The thing the piece that seems to be missing when people repeat that story is that this was a very special circumstance, like the hospital had to get special permission to be able to do that. The valve that they were printing it's a patented item, it's not something that you can make under regular circumstances, but the situation was so dire that they have special permission to be able to do that.

And so to think that somebody can just go into a hospital and start making ventilator parts is probably not the way that this is going to play out. It's going to be more what you're saying. Larger companies working in cooperation with authorities, with hospitals to make the parts that they need.

Peter Zelinski

Something like a ventilator is inherently just a complicated product with and it's defined by a lot of regulation and a lot of certification in the manufacturing process for very good reason. And and that's not the only manufacturing need. Why don't we pivot to a different manufactured product, right? There are some By comparison, simpler products that are also needed personal protective equipment in hospitals, healthcare workers, hospital workers, meeting and working with patients, basic protection for those workers in the form of masks, huge shortage of masks and there's a way that manufacturers are Stepping up and stepping in to try to address this shortfall to Stephanie, do you want to begin talking about that?

Stephanie Hendrixson

Yeah, so I'm talking about the the respirators, the the masks that go over your mouth and face and usually have some kind of filtration.

Peter Zelinski

Right, N-95 masks. And usually this is a disposable product. And usually you use just one mask per encounter with a patient. Meaning if you stuck by that standard, then we have a shortfall of millions of these masks and hospitals are already relaxing that rule and just keeping the masks in place through through a series of patients in a row.

Stephanie Hendrixson

Right and so something like that it could be 3D printed. There are some different some different companies out there talking about making reusable masks. I think the key thing to keep in mind you know, it's it's sort of similar to the to the ventilators, anything that's going to be in contact with somebody’s skin, you have to be really careful about your material choices there. I know that there's the hospital in Massachusetts that's asking people to help 3D print the masks using a design from Copper 3D. And the thing I think that's important to understand there is that they're not just using any off the shelf material, they're using a very specific PLA that has a copper fill, which is, which is allowing it to have antimicrobial properties and all that. So and then on top of that, there's also you need, you need a filter to add to that mask. So it's not just a plug and play printing application, you need to have the right materials you need to have the right filtration. And it's it's not something that I don't think anyone is encouraging, you know, go find the files on the internet and start printing. I know that hospital in particular is asking people to email first if they're if they want to be involved. We also had a story recently on our website about the the face shields, do you want to talk about that?

Peter Zelinski

So right, so the the masks you're describing there's a 3D printed solution to the mask potential. But even that is complex, just as you described. And another issue is the fit. A mask that's not optimally designed for this purpose. It could, it could put its wearer at risk unknowingly. And a huge problem with all of these quickly manufactured products is if though if the if the healthcare workers if the medical community suddenly feels at risk by them and feels they can't trust them, then all of a sudden that's that that could subtract capacity at rather than rather than add to the help.

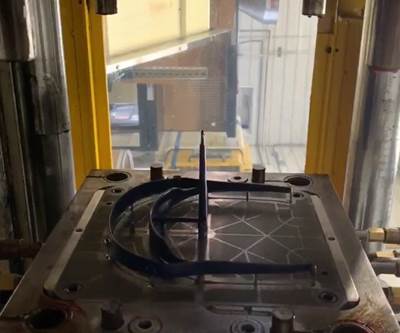

And so we are seeing a lot of 3D printing activity around these face shields. The the portion of it that holds the the clear the clear shield in place. This can be 3D printed, and we're seeing, we're seeing many companies involved in this. And really, there's so much activity around this space.

I'm going to generalize a little bit but there's really two realms in which this, this is playing out the face shield in particular, there's sort of a big scale approach happening, a large, multi institution multi organization effort, and then there is a crowdsource effort happening that's of service to individual hospitals who are reaching out. So I have been part of a working group. It's turned into a daily daily conference call and it is an alliance of some government agencies, defense medical device makers, hospitals, manufacturers, All organizing themselves around the question of how do we rapidly scale up production of personal protective equipment. And even something as simple as this face shield that we've been talking about? There's actually tremendous complexity to it that has to be addressed. So the part that holds the shield in place and holds it around the wearer's head that can be 3D printed, that's doable. This shield, it's got to be just the right material. Does that shield stand up to sterilization? Some of the existing shields, there's there's a there's a question whether it will there is a very large manufacturer in the material space that's part of this working group that is that is working to address that part of the challenge and working potentially to scale up production of this component.

So other issues there to give you a sense, the quality control as I said, Is it going to unknowingly fail the wearer at some crucial point? And then also logistics? How do you get a whole lot of face plates or face shields manufactured quickly? How do you get them distributed to all of the hospitals that potentially need them? So there are there are logistics organizations getting involved in this effort. organizations that are that are expert in that in that part of this challenge. So there is a large scale effort that is working to address that. And meanwhile, there are hospitals that are feeling their own desperation and wondering if they're going to get the supplies they need. And they are reaching out individually to manufacturers to service providers, particularly 3D printing service providers to try to get solutions and we're seeing lots of examples of that.

Stratasys to name one 3D printing manufacturer, they also have their own contract manufacturing arm, Stratasys Direct. And they have lots of customers who are users of their machines who are volunteering to get involved. On Stratasys ’s website we're seeing them sort of organize this effort, a simple interface of, Are you a 3D printing user who wants to get involved? Are you a hospital who needs help? And they're one example of one company in this space. And I'm not trying to play favorites here, but they're one that comes to mind of someone of a company really trying to step in and organize sort of the local level crowdsourcing part of this response for hospitals who are reaching out.

Stephanie Hendrixson

Two things to respond to in that. So one, the crowdsourcing efforts. If people are out there looking for ways that they can help and contribute, I would encourage them to look for those kinds of local efforts that like you're talking about. And also think about think beyond, you know, the PPE and the masks and ventilators. There are a lot of really useful designs out there for things like the hands-free door opener that can be really helpful in this time and don't require that kind of oversight.

The other thing I think that you sort of touched on is this idea of scale. You know, if we really do need mass quantities of these visors for the face shields, you know, at a certain point maybe it makes more sense to start looking at at a mold and and do it with injection molding rather than 3D printing. 3D printing doesn't have to be the the only answer or the ultimate answer for all of these problems we're facing.

Peter Zelinski

The well said 3D printing is an excellent first choice because it's a way to get started but as these things scale up, you have some some higher volume conventional process might well be the answer. So there's there are manufacturers also being affected by this. I think we'd all agree that the that the the afflicted and the medical providers are the most urgent part of this story right now. But businesses are affected by this manufacturing. are affected by this additive manufacturers who tend to be the audience for additive manufacturing media. And Stephanie, you've been talking to them over the last couple days, you've talked to quite a few. And any impressions or anecdotes you want to share?

Stephanie Hendrixson

Well, so actually to take it back a couple of weeks .So, earlier when earlier kind of before the coronavirus was really affecting the United States before all these states were in states of emergency, I was preparing to talk to one of our in house economist Michael Guckes, about just kind of the supply chain implications of what happened in China like shipping got very, very slow down. It still hasn't quite recovered. And I started reaching out to some companies in my network and heard some interesting stories. So there were 3D printing service bureaus that were actually getting more business because of this. And they were serving customers who previously would have been getting say injection molded plastic parts from from China or from other parts of Asia. They weren't able to get those parts reliably anymore. They weren't able to get them fast enough. So they started reaching out to companies with 3D printing expertise to see if those parts could be made quickly. A

nd that trend, it only seems, has continued. All of the service bureaus that I've talked to, in the past couple of days have had very similar stories, where they're making parts that can't be sourced or can't be accessed right now. They're making tooling to to make, you know, injection molded parts or thermoform parts here in the United States. Yeah.

And so I had a conversation just this morning with a 3D printing professional who said, you know, a lot of the customers, the new customers that he's getting right now are facing this choice between making, you know, maybe sourcing a 3D printed part that's more expensive than the molded part that they previously would have been selling. But it's the difference between selling something and maybe not making a great profit on it, not making a lot of margin on it, and selling nothing at all. And so 3D printing is starting to be seen a little bit more broadly as a good solution to these kinds of supply chain gaps. Does that gel with some of the stories you've been hearing?

Peter Zelinski

Oh, yeah, absolutely. So, so we're sitting at home right now, and a lot of us are and much of the country lives in states that either have these formal or recommended stay at home policies. But there are exceptions to those policies for essential businesses and essential institutions that need to stay open and are allowed to stay open.

And many types of manufacturing fall under that umbrella. So they're still working and and oftentimes without slow down, I'm hearing many cases of manufacturers in various sectors of Yeah, like we're we're still getting orders. We're still filling orders, we're still working. And so these supply chain issues, which were among the which was the first really the first rip of this this international crisis that began to affect the United States. It began it affected manufacturing with that. Now, we are looking at something very serious now, which is the manufacturing needs necessary to address the health aspects of the crisis. But that initial wrinkle is still there. The supply chain interruption and we're seeing a lot of providers of, of industrial 3D printing services are busy right now because they're needed right now. Because they're a way to get a fast tooling lists set up lists response to a for needed production.

Stephanie Hendrixson

Yeah. And so I guess one resource that we have for anybody who is who's in that situation, you're needing parts or you're in need of tooling. On our website. We currently have a Google map that shows the locations of 3D printing service providers in the United States and so if you are a manufacturer and you're struggling to get parts or you need fixturing or whatever it might be, it's worth a look to just see who is who is nearby you who's in your geographic region, and maybe reach out to some of those service bureaus, ask them about their capabilities. If there's something specific that you need, you know, come prepared with with a part file and and talk to them about your requirements and see if there's a solution there with 3D printing.

Peter Zelinski

So I guess that'll do it. Um, this was a little bit rough, kind of sketchy, I think in some places, but here's what we have to talk about now. And, and if the days to come are anything like the last few days, then the situation will change quickly and we will learn a lot more. And I think we'll be back pretty soon with another video like this one. Keep checking in at our website, additive manufacturing dot media, what we know about manufacturing's response to the coronavirus crisis and the effect on manufacturing by this crisis. as it's being posted there, and here there are many resources to find their additive manufacturing dot media and keep healthy and we'll see you soon.

Related Content

Q&A With Align EVP: Why the Invisalign Manufacturer Acquired Cubicure, and the Future of Personalized Orthodontics

Align Technology produces nearly 1 million unique aligner parts per day. Its acquisition of technology supplier Cubicure in January supports demand for 3D printed tooling and direct printed orthodontic devices at mass scale.

Read MoreFDA-Approved Spine Implant Made with PEEK: The Cool Parts Show #63

Curiteva now manufactures these cervical spine implants using an unusual 3D printing method: fused strand deposition. Learn how the process works and why it’s a good pairing with PEEK in this episode of The Cool Parts Show.

Read MoreStryker Using Additive for Implants

Using its “AMagine” process, Stryker creates components with a titanium alloy that mimics bone.

Read MoreActivArmor Casts and Splints Are Shifting to Point-of-Care 3D Printing

ActivArmor offers individualized, 3D printed casts and splints for various diagnoses. The company is in the process of shifting to point-of-care printing and aims to promote positive healing outcomes and improved hygienics with customized support devices.

Read MoreRead Next

Ventilator Manufacturing: Challenges and Likely Response During Coronavirus Crisis

Can we achieve something like a wartime transition to ventilator production, or will the response need to look different from this?

Read More3D Printing and Coronavirus: U.S. Additive Manufacturers Share Their Experiences

The COVID-19 outbreak has brought both setbacks and opportunities for American manufacturing. 3D printing companies share their stories.

Read MoreNeed Parts? These Additive Manufacturers Are Ready to Help

Disrupted supply chains are just one more effect of the coronavirus pandemic. These 3D printing service providers are ready to help fill production gaps with parts, tooling and prototypes.

Read More

.jpg;width=70;height=70;mode=crop)