A technician inspects the 3D printed pogo accumulator assembly on an RS-25 development engine at the Aerojet Rocketdyne facility located at NASA's Stennis Space Center. Photo Credit: Aerojet Rocketdyne

In May of 2019, NASA awarded Aerojet Rocketdyne a $1.79 billion contract modification for the production of six new RS-25 engines as well as updates to several existing engines that will be used to propel NASA’s newest heavy lift launch vehicle, the Space Launch System (SLS).

NASA and Aerojet Rocketdyne have already completed hot-fire testing of the new RS-25 engines outfitted with 3D-printed vibration damping devices known as a pogo accumulator assemblies. On their surface, these “pogos” resemble giant metal balloons. Functionally, they serve a vital role as shock absorbers that dampen oscillations caused by blasts of propellants between the vehicle and the engine.

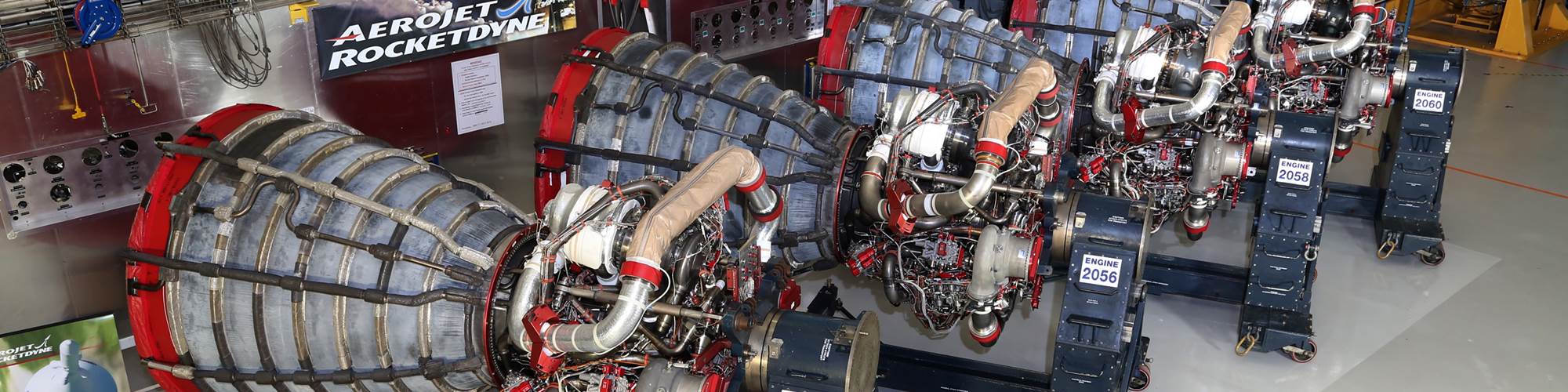

Aerojet Rocketdyne displays the four RS-25 engines slated to fly on Artemis-1, the first flight of NASA's SLS rocket, at its facility located at NASA's Stennis Space Center. Photo Credit: Aerojet Rocketdyne

A pogo accumulator assembly stabilizes this so-called “pogo effect,” which makes it critical to astronaut and vehicle safety. In fact, it is this thrust vibration phenomenon that occurred so violently on the Apollo 6 that it shook off panels of the lunar module adapter during flight.

The pogo assembly consists of two components: the pogo accumulator and pogo-z baffle. Aerojet Rocketdyne has additively manufactured both components via powder bed fusion — a feat that eliminated more than 100 welds and reduced costs by nearly 35 percent and production time by more than 80 percent on the pogo accumulator alone. The company turned to EOS and Concept Laser machines for the bulk of its metal AM parts, including the pogo, which it prints with Alloy 718 (also known as Inconel 718), because this high-strength, nickel-based super alloy can reliably withstand operating environments, including not only high pressures but alsotemperature gradients that range from negative 423°F to more than 2,400°F.

RS-25 engine inspection inside the engine assembly room at Aerojet Rocketdyne's Stennis Space Center Facility. Note the pogo assembly on the left side of the nearest rocket. Photo Credit: Aerojet Rocketdyne

Alan Fung, senior engineer and additive manufacturing team leader for Aerojet Rocketdyne, says that one of the greatest benefits of AM ties directly to the development cycle and lead-time risks that the company mitigates through simulation software and careful machining processes. “When you get into SLM (selective laser melting), or when you talk about these additive processes, you realize, oh, I can increase this blade angle a little bit,” Fung says. “You can do that in development. You can incorporate it and you're not locked into the geometry.”

Related Content

-

Video: For 3D Printed Aircraft Structure, Machining Aids Fatigue Strength

Machining is a valuable complement to directed energy deposition, says Big Metal Additive. Topology-optimized aircraft parts illustrate the improvement in part performance from machining as the part is being built.

-

How Norsk Titanium Is Scaling Up AM Production — and Employment — in New York State

New opportunities for part production via the company’s forging-like additive process are coming from the aerospace industry as well as a different sector, the semiconductor industry.

-

3D Printed Lattice for Mars Sample Return Crash Landing: The Cool Parts Show Bonus

NASA Jet Propulsion Laboratory employs laser powder bed fusion additive manufacturing plus chemical etching to create strong, lightweight lattice structures optimized to protect rock samples from Mars during their violent arrival on earth.