Articles

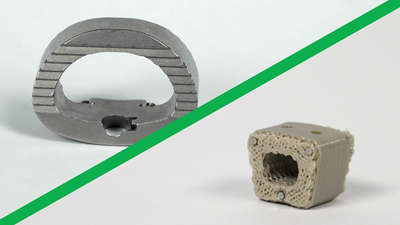

FDA-Approved Spine Implant Made with PEEK: The Cool Parts Show #63

Curiteva now manufactures these cervical spine implants using an unusual 3D printing method: fused strand deposition. Learn how the process works and why it’s a good pairing with PEEK in this episode of The Cool Parts Show.

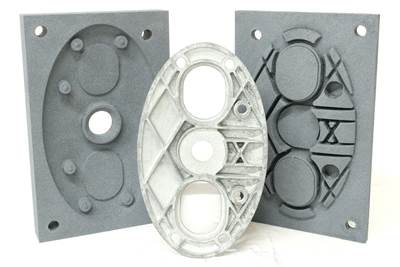

WatchIn Casting and Molding, AM Simplifies Conventional Manufacturing

In new ways, additive processes are streamlining and enabling metal casting and plastic injection molding.

Read MoreCuriteva Implant Manufacturing Process: The Cool Parts Show All Access

Todd Reith explains the workflow for creating Curiteva’s 3D printed spine implants from PEEK.

WatchCuriteva on Ti vs PEEK: The Cool Parts Show All Access

Curiteva produces cervical spine implants using PEEK, but today most spine implants are made of metal — specifically, titanium. There are very good reasons to choose titanium, as Erik Erbe describes in this interview clip. But, PEEK may have the edge in terms of stiffness, osseointegration and another important factor we learned about.

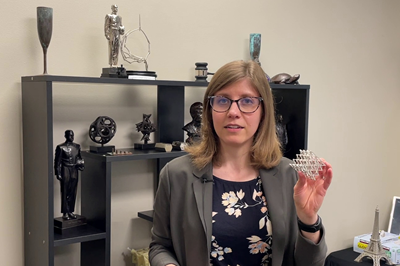

WatchA Look at Lattice: The Cool Parts Show All Access

Lattice structures are great, but they have to end somewhere. When designing head padding made from lattices, how do you design the surfaces where the pads adhere to the helmet? Marek Moffet, chief technical officer for General Lattice, talks about that here.

WatchFoundry Lab: How Casting in a Day Will Improve the Design of Metal Parts (Includes Video)

The company’s digital casting process uses 3D printing, but the result is a cast part. By providing a casting faster than a foundry, the company says effective prototyping is now possible for cast parts, as well as bridge production.

WatchThe AM Ecosystem, User Journeys and More from Formnext Forum Austin: AM Radio #43

Sessions and conversations at the first U.S. Formnext event highlighted the complete additive manufacturing ecosystem, sustainability, the importance of customer education, AM user journeys and much more.

ListenFormlabs Part Removal Mechanism Enables Lights-Out Production

A build platform overcoming the need for manual part removal enables automated part handling, and therefore continuous production from one build cycle to the next.

Read More3D Printing Project to Advance Medical Device Customization

Creating flexible medical devices requires innovations in design, materials science and advanced manufacturing. A research team aims to refine and implement new methods of 3D printing medical devices.

Read MoreMeet The Cool Parts Showcase Winners

The Cool Parts Showcase winners for 2023 were announced at Formnext Forum Austin. Watch the award presentation here.

WatchPossibilities From Electroplating 3D Printed Plastic Parts

Adding layers of nickel or copper to 3D printed polymer can impart desired properties such as electrical conductivity, EMI shielding, abrasion resistance and improved strength — approaching and even exceeding 3D printed metal, according to RePliForm.

Read MoreHow Electroplating Works for Polymer 3D Printed Parts

Baltimore-based RePliForm specializes in electroplating of 3D printed polymer parts for functional applications. This video explores how the process works, and potential benefits and uses for this technique.

Watch