Watch: Production Additive Manufacturing Is Here

Additive systems are proving capable for cost-effective production even of parts that aren’t all that complex. This will be the next phase of AM.

Additive manufacturing technology is a production resource. Manufacturers need to recognize this. The idea that AM is only for complex parts and only for low quantities is being disproven by AM systems coming to market.

What Companies Use Additive Manufacturing for Production?

While not an exhaustive list, the following companies represent a variety of industries, AM processes and materials.

Chevrolet. The automaker integrated a 3D printed seal component to improve fuel economy in its Tahoe SUV.

Dustless Technologies. After years in China, the vacuum accessory maker moved production to the U.S. thanks to 3D printing.

Cobra Moto. To get its all-electric youth motocross bike to market, the company opted for 3D printing over mold tooling.

Aerosport Additive. Rather than focus on increasing volumes alone, Aerosport is seeking out the niches where AM materials, costs and capabilities align.

Rekkie. This company’s augmented reality ski goggles are made possible through Multi Jet Fusion.

Tangible Solutions. Titanium implants are printed on the company’s metal 3D printers, then flow toward the back of the building for machining, cut-off, deburring and cleaning.

RMS. The medical device provider prints as many as 20,000 titanium implants per month on 30 powder bed fusion machines.

Emerson. The company’s anti-cavitation trim is made in an essentially unattended process through laser powder bed fusion. Approximately 600 have been installed in industrial ball valve applications.

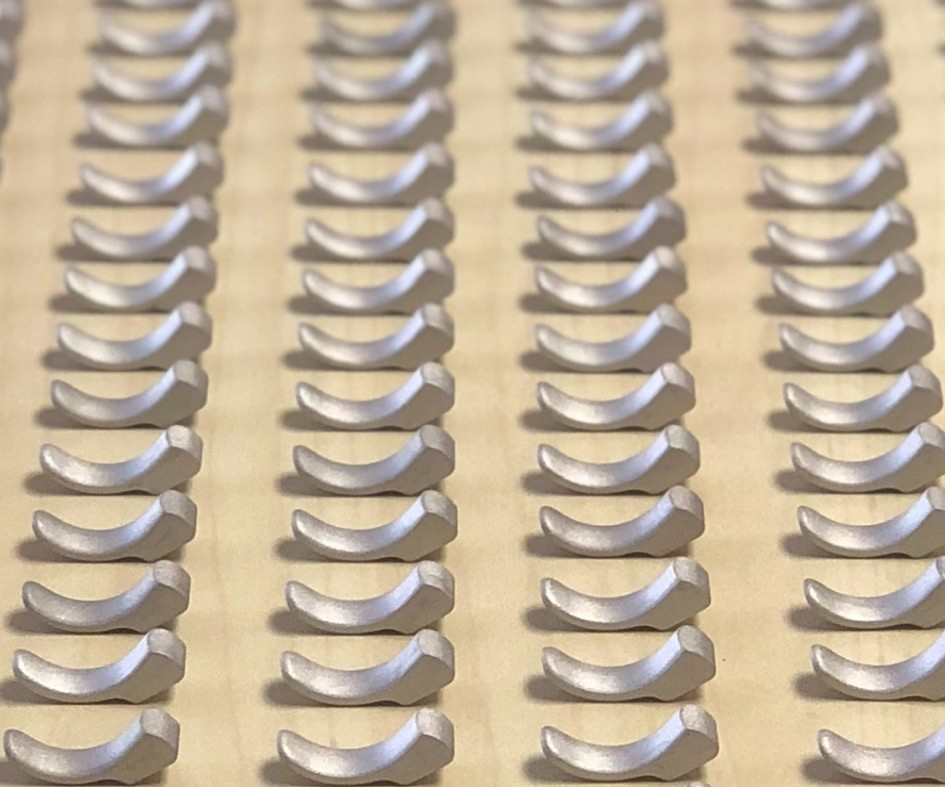

3DEO. Using its own additive process and platform, 3DEO produces 13,000 ball return tubes for aircraft per year.

Transcript

Additive manufacturing for scale production is coming. In some places, it's already here.

There was an idea not long ago that additive is for very complex, high-end parts at low quantities. But additive systems are coming to market that deliver high production rates, repeatable production, cost-effective production—even for parts that aren't all that complex.

Additive technology is advancing. Production is the area where the advances might be profound. We need to watch this.

Additive is taking its place in manufacturing, and the next step—what's coming—is additive taking its place in manufacturing of production quantities.

3D Printing for Production

Additive manufacturing is becoming a viable option for manufacturing parts at scale. Manufacturers are 3D printing volumes ranging from “batch size one” to full-scale production. New products and supply chains offer additional opportunities for AM to be the manufacturing technology of choice. VISIT THE ZONE

Related Content

-

3D Printing with Plastic Pellets – What You Need to Know

A few 3D printers today are capable of working directly with resin pellets for feedstock. That brings extreme flexibility in material options, but also requires greater knowledge of how to best process any given resin. Here’s how FGF machine maker JuggerBot 3D addresses both the printing technology and the process know-how.

-

At General Atomics, Do Unmanned Aerial Systems Reveal the Future of Aircraft Manufacturing?

The maker of the Predator and SkyGuardian remote aircraft can implement additive manufacturing more rapidly and widely than the makers of other types of planes. The role of 3D printing in current and future UAS components hints at how far AM can go to save cost and time in aircraft production and design.

-

DMG MORI: Build Plate “Pucks” Cut Postprocessing Time by 80%

For spinal implants and other small 3D printed parts made through laser powder bed fusion, separate clampable units resting within the build plate provide for easy transfer to a CNC lathe.