Video: How Additive Manufacturing Is Advancing the Space Industry

By making launch vehicles more efficient and easier to manufacture, AM lets small companies play a significant role in space. Here is a conversation with an aspiring startup.

By making launch vehicles more efficient and easier to manufacture, additive manufacturing enables startups to enter the space industry. I discussed this with Max Haot, CEO of Launcher, and Ankit Saharan, R&D and applications development manager with EOS.

Transcript

Peter Zelinski, Additive Manufacturing

Additive manufacturing is advancing the space industry. Thanks to additive, small companies can commercialize space. I recently spoke with Launcher. This small startup is working with EOS to build the components of an efficient launch vehicle for small satellites. I spoke with Max Haot of Launcher and Ankit Saharan of EOS.

Why is additive manufacturing so crucial to realizing a small cost-effective launch platform?

Max Haot, Launcher

The key to build an orbital launch vehicle is performance and the key to that is the engine. If you look at a rocket, it's mostly tanks, but if you look at the complexity and what really defines a rocket, it's its engines.

In liquid rocket engines, to use your propellant effectively with the right fuel consumption and performance to reach orbit, you need to reach combustion temperatures that are twice as high as those of the best metal we have, such as Inconel. The way to do that is you have to build internal cooling channels and do a regenerative cooling. Build some pretty lightweight nozzles in a chamber where you run the kerosene through the nozzle wall to cool it so that you can have an internal combustion temperature higher than the melting point of your nozzle.

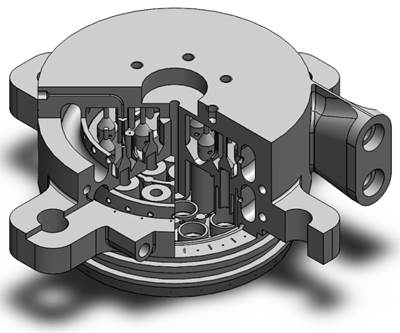

Now, traditionally these rocket nozzles and these internal intricate channels are very complicated and expensive to develop. The tooling required; the specialized craft … usually machining and brazing of an inner layer and an outer shell are required. It doesn't allow startups to really get involved. Since the advance of 3D printing, and with EOS as our partner, we're now able to design a rocket engine with a cooling chamber and a nozzle. You go straight from CAD to printing and you're able to have all these internal geometries and spiraling cooling channels.

Ankit Saharan, EOS

Max was earlier hinting at how many challenges people have [with] a startup, not having access to capital and expenditure. To be able to go through those million-dollar iterations, waiting for those molds; he did thisiteration in a couple of months. Doing that in a traditional sense would take years even if you were with a big company. From our side, we were able to actually do that in a really fast way. We were able to go through a lot of iterations on the design challenge, especially with the cooling channels on the side of the combustion channels, not only going straight through the holds but actually going spiral, which would be impossible to machine.

Peter Zelinski

We talk about the design freedom of additive manufacturing. Often when we say that, we think of geometric freedom; very intricate forms. You're describing a different kind of design freedom which is greater freedom to perfect your design by iterating very easily.

Max Haot

We actually are about to experiment with copper alloy. We were able to produce the exact same path in a different material to test. That’s yet another advantage that probably would need a different process for a given material.

One of our key objectives at Launcher is to not only build a 3D printed engine but to build the highest performance in the market. How can we, using additive manufacturing at a smaller size than this big engine, reach similar performance but at the cost of additive manufacturing? One aspect of that is to push the highest combustion temperature and have the most effective cooling. We are also R&Ding other materials, such as copper, before we lock down on a final decision.

Peter Zelinski

Would you describe another component of the rocket for which additive manufacturing is important?

Max Haot

The next breakthrough is injectors. We are transitioning to coaxial injectors. An injector could have hundreds of different parts that have to be machined traditionally, assembled and tested. You can now build an injector in a single part and weave in geometries and passage and even new ideas of how to distribute the flow before it reaches the chamber. It is unprecedented creativity. You know, some of our designers don't necessarily even have the background [knowledge] of how it was done traditionally. They know what the end result needs to be and the freedom and the creativity that 3D printing gives allows these new types of injectors.

Related Content

8 Cool Parts From Formnext 2023: The Cool Parts Show #65

New additive manufacturing technologies on display at Formnext were in many cases producing notable end-use components. Here are some of the coolest parts we found at this year’s show.

Read MoreWill the Successes of NASA’s RAMFIRE Project Lead to an Operational Aerospike Engine?

NASA’s RAMFIRE project has additively manufactured a 36-inch diameter aerospike nozzle with complex integral coolant channels for a more efficient way to propel rockets to outer space. NASA engineers will use this as a proof of concept to inform future component designs.

Read MoreCryogenic Tanks for Space Refueling: The Cool Parts Show All Access

NASA's Paul Gradl describes an important application of AM beyond the spacecraft itself: refueling the spacecraft. Directed energy deposition offers the most practical way to produce aluminum tanks to keep fuel supercool.

Read MoreSciaky Manufactures Critical EBAM Component for Intuitive Machines’ Moon Landing

The Sciaky engine component was the upper section of the IM-1 lander’s main engine nozzle, which provided the main source of thrust for descent in the February 2024 mission to the Moon.

Read MoreRead Next

Orion Gets a Lift from Electro-Static Dissipative (ESD) Material

NASA’s Orion spacecraft will include parts 3D-printed from electro-static dissipative Antero 800NA from Stratasys. Developing this material was an exercise in working within constraints.

Read MoreAdditive Technology Delivers Small Satellites to Space

Researchers at the German Aerospace Center (DLR) have developed a reusable rocket engine specifically for the launch of small satellites. The complex injector heads are 3D printed which unlocks additional performance, reduces the parts count, speeds up production time, and reduces weight and costs.

Read MoreBike Manufacturer Uses Additive Manufacturing to Create Lighter, More Complex, Customized Parts

Titanium bike frame manufacturer Hanglun Technology mixes precision casting with 3D printing to create bikes that offer increased speed and reduced turbulence during long-distance rides, offering a smoother, faster and more efficient cycling experience.

Read More