Launcher Uses Additive Manufacturing to Optimize Satellite Design

Launcher depends on Velo3D to 3D print complex rocket compounds for low-cost, small satellite delivery systems.

Share

Read Next

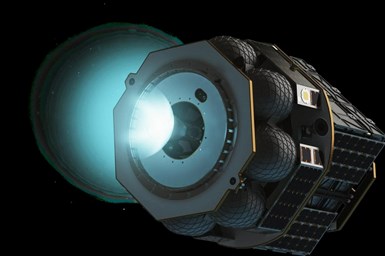

Launcher’s Orbiter satellite transfer vehicle and platform, powered by 3D printed engines, will first hitch a ride with SpaceX this fall. Photo Credit: Launcher Inc.

Sixty-five years after the first orbital satellite was launched into space, more than 5,000 satellites are in service with roughly half of them placed into low earth orbit (LEO) over the past two years. Launcher Inc., an aerospace company based in Hawthorne, California, seeks to be a part of what Launcher founder and CEO Max Haot calls the ‘small satellite revolution.’

However, Haot and Launcher’s head of manufacturing, Tim Berry, are quick to point out that none of this would be possible without additively manufactured metal components, including some which were produced on a Sapphire 3D printing system from Velo3D.

“The Velo Sapphire, with its ability to reliably print complex geometry, made it very easy for us to pivot in the face of shifting priorities,” Berry says.

Launcher began its most recent development efforts with its Orbiter satellite transfer vehicle and platform, rather than the rocket’s main stage which would carry it into space. Because no rocket flies without a rocket engine, Launcher licensed the drawing for a space-proven turbopump, then set about improving its design using additive manufacturing (AM) technology. Unfortunately, no metal AM equipment provider could produce many of the necessary components.

“The team at Velo3D took the challenge, and we ended up with a finished part that exceeded all of our performance objectives,” Berry says. “That was the beginning of our relationship.”

Before investing in its own AM equipment and other metalworking machinery, Launcher subcontracted most of its parts to Velo3D’s network of contract manufacturers.

“As a modern space and rocket company, we have several important goals,” Haot says. “The first and most obvious one is for Orbiter to deliver the lowest cost in the industry for the highest propulsive capability. But, to achieve that, it’s critical to have in-house design and manufacturing capabilities.”

As it so happens, the Orbiter’s 22-liter tanks exactly match the Sapphire’s build volume. Launcher began by printing the parts out of Inconel and, although they performed quite well, Berry and the team started looking for ways to optimize the design. Moving to lighter weight titanium was an obvious choice.

“That’s what brought us to our second machine from Velo3D,” Berry explains. “It can print the exact same tank but with less weight and higher pressure capabilities.”

One of the biggest advantages of having in-house printing capabilities is that Launcher can continually push for more aggressive designs and higher performance without losing a lot of time or spending a lot of money. As such, the company is 3D printing a range of components on its Sapphire systems, such as brackets and other secondary structures, combustion chambers and injectors.

“We don’t have to completely change our design to make it work with the Velo3D printer,” Berry says. “And in most cases, we can use whatever geometry we had planned. There’s no need to make a bunch of compromises like there so often is with metal AM.”

Related Content

-

Reusable LOX/Kerosene Engine Completes First Successful Full-System Test Flight

Galactic Energy Space Technology announced the first successful full-system test flight of its Welkin 50-ton reusable LOX/kerosene engine. To date, this is the highest thrust LOX/kerosene engine in the Chinese commercial aerospace playing field which has officially entered the engineering and manufacturing phase.

-

3D Printed Lattice for Mars Sample Return Crash Landing: The Cool Parts Show Bonus

NASA Jet Propulsion Laboratory employs laser powder bed fusion additive manufacturing plus chemical etching to create strong, lightweight lattice structures optimized to protect rock samples from Mars during their violent arrival on earth.

-

Will the Successes of NASA’s RAMFIRE Project Lead to an Operational Aerospike Engine?

NASA’s RAMFIRE project has additively manufactured a 36-inch diameter aerospike nozzle with complex integral coolant channels for a more efficient way to propel rockets to outer space. NASA engineers will use this as a proof of concept to inform future component designs.