Thyssenkrupp's Low-Risk Venture into 3D Printing Began with the End Effector

Thyssenkrupp Bilstein of America's investment in additive manufacturing technology has been relatively low-risk and low-cost. And yet, layer by layer, the wins are adding up.

[Editor's note: This company has gone farther with 3D printing since we posted this story. We have posted a more recent article on how 3D printing is helping Thyssenkrupp Bilstein advance with collaborative robots (cobots).]

It was an early evening near Christmas 2018, when Fabian Schmahl, Thyssenkrupp Bilstein of America’s president and chief executive officer, experienced a minor panic. A colleague had just informed him that a plastic coupling component on one of the company’s new collaborative robots (cobots) had cracked and broken beyond repair. Apparently someone had adjusted the table on which the cobot arm was placing parts, which caused the arm to crash into the table and smash the plastic piece. This would have been a minor mishap if key management of the German-based company wasn’t due to tour the facility the next morning, and if the team had not been eager to show them the latest cobot automation technologies on Bilstein of America’s production floor.

But the panic didn’t last long. That same colleague told Schmahl not to worry, that they would simply 3D print a replacement part overnight and install it early the next morning before anyone was the wiser.

As the story goes, the print job ran through the night, finished and was installed five minutes before the board’s arrival. And as evidenced by the increased use of cobots at Bilstein (there are now eight cobots, all made by Universal Robots, spread across four stations at the plant), the cobots were a smashing success.

But let’s not overlook the important twist here—the quick-thinking utilization of 3D printing that made this happy ending possible. Bilstein is perhaps the premier suspension supplier for the performance and luxury auto market, and its investments in Industry 4.0 technologies are evident. Yet so far, the company’s investment in additive manufacturing (AM) technology has been relatively low-risk and low-cost, even though the savings on robot components—notably end effectors—have been significant.

Risk Made Easy

Bilstein purchased its first printer about four years ago, a Raise3D system that found its home not on the factory floor but in the adjacent office area. Aldo Albieri, operations manager for Bilstein, says that while it took several months to learn the ins and outs of the new machine, it took only three months before Bilstein wanted to add a second printer. “It was a little bit hard at the beginning, but then once we had it in place it proved itself to be incredibly cool and easy to use,” he says. “So all the fears we had in the beginning went away. The first one broke the ice and it opened a path.” Today the company has five printers spread throughout its campus.

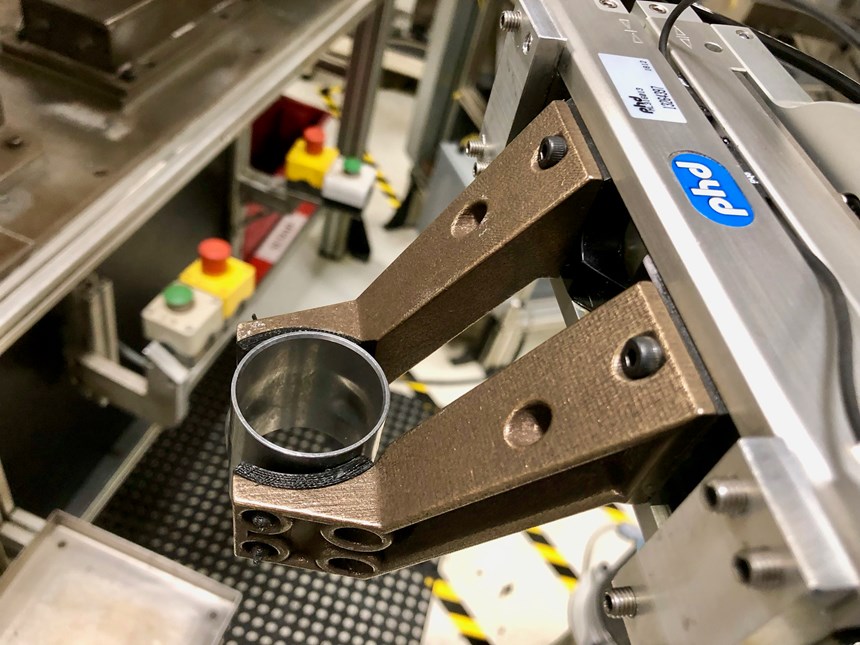

Meanwhile, Bilstein’s first cobot arrived just two years ago. And while Bilstein utilizes its printers for ad hoc prototyping and tooling needs—including simple but innovative workspace solutions like mountable toolholders conceived and printed by co-op students from nearby colleges and universities—additive has become the go-to solution at Bilstein for cobot end effectors, spacers and grippers. Printed primarily with polylactic acid (PLA) and thermoplastic polyurethane (TPU), individual components of these relatively simple parts can cost upward of $800 when purchased via cobot part suppliers. By contrast, most end effector components are printed in-house with the Raise3D systems at a cost of less than $5 worth of material. Some of the grippers have been in use on the cobots for more than a year, proving that durability of the PLA and TPU materials is not an issue.

Now, building on the proficiency that has come from making the robot parts, the company is using 3D printing more and more as a tool for internal development for part designs as well as for product simulations for prospective customers. Albieri says that 3D printing has become another tool in the toolbox when it comes to quoting new business for the company. “Usually the way it works is we would look at some drawings and then look at a bill of material to understand the cost,” he says. “And today it’s automatic that when we're in one of those meetings, instead of looking at a 2D drawing where maybe not everybody understands every detail of the concept, we will bring in a 3D printed part that you can touch and understand how it functions and how it’s put together. I think that makes it a completely different level of discussion.”

“Failure is not really a failure in this case; it becomes an evolution instead.”

Schmahl agrees. He pushes his team to experiment with 3D printing and to test new ideas made possible by 3D printing the tooling for a newly conceived part or design. “I think this is really one of the biggest pieces of this story,” he says. “I try to enable the team to try things out and take more risk. Because today if somebody has an idea, usually you would have to go outside to get tooling that’s quoted at several thousand dollars. You don’t want to waste it if it fails. But the reality is now we can print it literally for a couple of dollars and easily modify it as needed. Failure is not really a failure in this case; it becomes an evolution instead.”

Schmahl also admits that, in addition to tooling and design iterations, one of the often overlooked benefits of 3D printing at Bilstein is less tangible but still significant. “Quite often, our parts and components are designed and produced not only for performance and functionality but also for design features and an aesthetic perspective.” To wit, it’s hard to miss the embossed “BILSTEIN” logo emblazoned across the rock shield prototypes shown in the photos. 3D printing for prototyping gives designers the freedom to explore and refine aesthetic forms. “We are maybe considered a traditional German company oriented toward getting the best function out of the product,” Schmahl says. “But in automotive, while functionality is incredibly important, there’s a big emotional piece to it too. We can’t ignore that.”

Related Content

Chuck Jaws Achieve 77% Weight Reduction Through 3D Printing

Alpha Precision Group (APG) has developed an innovative workholding design for faster spindle speeds through sinter-based additive manufacturing.

Read MoreLooking to Secure the Supply Chain for Castings? Don't Overlook 3D Printed Sand Cores and Molds

Concerns about casting lead times and costs have many OEMs looking to 3D print parts directly in metal. But don’t overlook the advantages of 3D printed sand cores and molds applied for conventional metal casting, says Humtown leader.

Read MoreVideo: 5" Diameter Navy Artillery Rounds Made Through Robot Directed Energy Deposition (DED) Instead of Forging

Big Metal Additive conceives additive manufacturing production factory making hundreds of Navy projectile housings per day.

Read MoreUltiMaker Targets Light Industrial Applications With 3D Printer Designed for the Factory Floor

The company’s Factor 4 3D printer introduced this week is designed to complement conventional manufacturing equipment including CNC machining and automation.

Read MoreRead Next

One-Piece Robot Gripper Actuated by Shop Air

The pneumatic gripper 3D-printed as a complete working unit has demonstrated its effectiveness for continuous operation over time. It is one illustration of the role additive is liable to play in making robotic automation easier.

Read MorePostprocessing Steps and Costs for Metal 3D Printing

When your metal part is done 3D printing, you just pull it out of the machine and start using it, right? Not exactly.

Read More3D Printed Polymer EOAT Increases Safety of Cobots

Contract manufacturer Anubis 3D applies polymer 3D printing processes to manufacture cobot tooling that is lightweight, smooth and safer for human interaction.

Read More