The Factor 4 has an MSRP of $20,000 and is designed in a modular fashion so repairs and maintenance can be made easily on-site, without having to move this 260-lb machine once installed. A storage cart specifically designed for use under this printer is being introduced as well (but was not on-site when I visited the company’s Manhattan headquarters).

Since Ultimaker and MakerBot merged in 2022, integrating the two operations has been an exercise in piecing together complements. MakerBot, which has always had a strong presence in the nonprofessional 3D printing space, has transformed into the brand name for the joint UltiMaker’s line of educational products. The Ultimaker S5 and S7 lines have carried on as primarily prosumer models, while the Method brand (initially launched by MakerBot) is carried on by the more robust Method XL, offering the company’s largest build volume and targeted toward industrial and engineering applications. Each existing machine platform has been slotted into a specific niche, now all joined together with software offerings including the Ultimaker Cura slicer and Digital Factory build management platform.

But now, with the launch of the Factor 4 this week at Hannover Messe, the new UltiMaker is expanding its ecosystem further into industrial manufacturing territory with a 3D printer that complements its other machines but is firmly positioned for use on the factory floor. (The machine’s name is a bit of a play on this expected use case.) I traveled to UltiMaker’s U.S. headquarters in New York City earlier this month to learn more.

“The Method XL was our first step into the industrial area,” says Michael Mignatti, vice president of central development. “But there was still a gap we needed to solve in validating, developing and producing more critical components.”

With the Factor 4, UltiMaker is now squarely targeting industrial users seeking a robust 3D printer to deliver those critical components that can help keep other processes running. This larger machine — not quite a desktop format, though not quite a floor-standing model, either — is compact and clean enough to run in an office environment but is designed to withstand the demands of a machine shop or factory environment as well.

“Our portfolio follows the use cases,” says Jim Franz, president, Americas, citing demand from current UltiMaker customers for a machine that can handle a wider variety of materials and more challenging applications, as well as the significant opportunity represented by potential customers not yet within the company’s ecosystem. Current and expected uses for this platform include durable automation tooling, CNC machining fixtures, replacement parts and small runs of end-use items.

Key Features of the Factor 4

While the Factor 4 perhaps builds on lessons from the Method XL and previous 3D printers, it is not derivative. Instead, the company set out to make an industrial-focused machine that would not only be able to produce fixtures and other tooling to support conventional manufacturing (in addition to small runs of end-use parts) but one that would fit easily into such a workflow.

A few key features make this possible:

- An actively controlled build chamber. The new high-temperature print core in this machine prints up to 340°C, while the bed can heat the build volume to 70°C, expanding the types of materials that can be printed. The S Series and Method XL printers already support extrusion temperatures up to 300°C, but “that extra 40 degrees unlocks a whole lot of potential,” says Luis Rodriguez, application engineer. For example, one of the initial materials UltiMaker is offering with this machine is PPS-CF, a 10% carbon-filled material that handles more like a lightweight metal than a polymer composite and is suitable for applications such as CNC machining fixtures. The enclosure is also sealed to maintain temperature control and integrates a HEPA filter for emissions management.

The Factor 4 offers a build volume of 330 × 240 × 300 mm and a heated bed ranging to 120°C. The machine uses swappable print cores like others in the UltiMaker S Series ecosystem and supports dual-material printing.

- A direct-drive printhead. Compared to past machines where filament was pushed through Bowden tubes to reach the hot end, the direct-drive on the Factor 4 places the extrusion mechanism much closer to the print core and enables more reliable, consistent extrusion, particularly for flexible materials such as TPU. One Beta tester of this machine who has had success with printing TPU via S-series printers in the past is now able to achieve faster speeds and higher productivity thanks in part to this hardware choice.

The direct-drive extrusion mechanism opens more material opportunities, particularly in soft polymers. This sample part is made from Shore 70A filament produced by Recreus.

- Closed-loop control. Also contributing to more reliable printing are a half-dozen sensors measuring material flow and temperatures at various locations within the printer enclosure. Real-time material extrusion is compared to expected flow and adjusted accordingly, while air flow can adjust automatically to maintain temperatures within ±3 to 5°C. The Factor 4 is the first UltiMaker 3D printer to use closed-loop control; in addition to peace of mind, the feature is intended to save users time by enabling them to skip the test prints that were often needed to dial in the process.

- On-machine print process reporting. The same sensors that enable closed loop control are also used to gather data for traceability. Disruptions to the printer process such as a temperature drop caused by the machine door opening unexpectedly are recorded and correlated to specific points in the G code, so that potential problems can be investigated. Reports are accessible via a USB drive for machines that are not internet connected, as is the case in many defense and other sensitive installations.

- Integrated material management. Past UltiMaker printers have offered options to integrate filament cabinets and feeders, but the Factor 4 has this capability built-in. A climate-controlled cabinet below the build chamber ensures filament is stored at below 15% humidity and can hold up to six spools of material. The printer itself can support two-material printing so this inventory might be divided between build and support materials, or filaments of varying durometer. But the capacity might also be used to supply enough material for a large print left to run unattended overnight or over the weekend.

An integrated storage cabinet keeps filament dry and temperature-controlled. Different materials can be loaded to support multimaterial printing or multiple spools of the same material for larger parts and overnight work.

Machining, Automation and Beyond

Where the company’s previous 3D printers have already been adopted in many applications in the automotive, aerospace, defense and tooling spaces, UltiMaker sees the Factor 4 carrying this technology into more demanding applications.

End-use production parts will make up some portion of its use cases (one beta tester, for example, has used this machine to produce an adapted exhaust for a chain saw), but this is not the primary focus. Instead, Franz and other company leaders see the Factor 4 as a promising offering for manufacturing spare and replacement parts, factory line maintenance, and especially tooling.

Workholding for CNC machining is one compelling example. The PPS-CF material supported by the Factor 4 is particularly well suited for producing jigs, fixtures and other workholding implements that can take the place of more expensive machined metal. One beta tester of the machine, for example, is a brake manufacturer that uses this filament to produce a fixture that is subject to high temperatures and coolant spray in a CNC milling process.

The PPS-CF filament makes it possible to produce durable machining fixtures like this one used in CNC processes.

“This machine is made to keep your CNC running, ” says Ryan Singler, business development and sales enablement. “This thing can be making jigs and fixtures for the next job while you’re making money with your CNC on the job before, as you’re writing your next moneymaking job.”

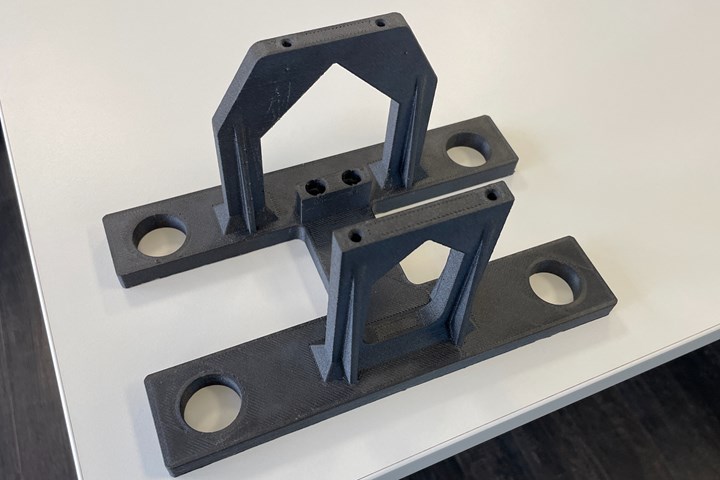

Another major opportunity lies in automation. Many assembly and packaging lines rely on components that wear, and this machine could offer the chance to manufacture a needed bracket or gasket on the spot without waiting for an ordered part to arrive. UltiMaker also sees ample opportunity for the Factor 4 as a solution for manufacturing conveyor pucks, assembly fixtures, robot end-effectors and the like.

“In the future, for every three robots you’ll need one 3D printer,” says Michiel Alting von Geusau, CEO. “The new factory floor will be far more flexible.”

Factory tooling is a primary target application for the Factor 4. Companies that rely on conveyor lines often need specialized “pucks” to carry parts along them. Fixtures like this one printed from TPU can be easily customized to the application and 3D printed from materials that won’t mar or damage the item.

Related Content

Airless Basketball Shows Promise of 3D Printed Lattices: The Cool Parts Show Bonus

Successfully matching the performance of a standard basketball demonstrates the control possible over the mechanical properties of digital materials.

Read MoreConcept Sneaker Boasts One-Piece 3D Printed TPU Construction

The Reebok x Botter Concept Sneaker Engineered by HP premiered at Paris Fashion Week, hinting at manufacturing possibilities for the future of footwear.

Read MoreUnderstanding PEKK and PEEK for 3D Printing: The Cool Parts Show Bonus

Both materials offer properties desirable for medical implants, among other applications. In this bonus episode, hear more from Oxford Performance Materials and Curiteva about how these companies are applying PEKK and PEEK, respectively.

Read MoreThis Drone Bird with 3D Printed Parts Mimics a Peregrine Falcon: The Cool Parts Show #66

The Drone Bird Company has developed aircraft that mimic birds of prey to scare off problem birds. The drones feature 3D printed fuselages made by Parts on Demand from ALM materials.

Read MoreRead Next

Metal Parts Are Now Within Reach for Users of Polymer 3D Printers

An option for accessible metal 3D printing: New metal composite filament from BASF Forward AM has made it easy for Austrian company Sparox 3D to pivot its Ultimaker FFF capacity into metals, without major additional investments in skills or equipment.

Read MoreHow AM Enables Cobot Automation for Thyssenkrupp Bilstein (Includes Video)

The shock absorber maker has responded to its staffing shortages through extensive use of collaborative robots. In-house 3D printing makes this possible by providing the related hardware needed to complete the cobot-automated cells.

Read MoreWhy Heineken Sees Breweries in More Countries As a Likely Benefit of 3D Printing

This video describes various ways 3D printing streamlines and supports beverage production.

Read More

.jpg;width=70;height=70;mode=crop)