Broadly speaking, humans have focused our engineering on brute-force mechanical processes because we’ve lacked the technical capacity to mimic nature. This isn’t for a lack of imagination on our part. Leonardo da Vinci modeled his schematics for human flight based on the observations of birds back at the start of the 16th century. But the technological capability to engineer and manufacture the complex geometries and mechanics of living organisms—the natural geometries, material properties and mechanics that have evolved and improved over the course of eons—has been largely absent until recent innovations in materials development and additive manufacturing.

This nature-mimicking concept, called biomimetics, inspired a recent breakthrough made by researchers working at the University of Minnesota (UofM) in the field of soft robotics. In an article published earlier this year in the journal Extreme Mechanics Letters, lead researcher and UofM Ph.D. candidate Ghazaleh Haghiashtiani helped demonstrate that, for the first time, dielectric elastomer actuators (DEAs) can be fully 3D printed and layered with soft ionic hydrogel-elastomer hybrid material systems. That’s a lot to unpack, but this capability holds promise for printing entire soft robots made from a material analogous to human skin—including its ability to carry and respond to electrical stimuli.

The materials at the center of Haghiashtiani’s research are ionic hydrogel-elastomer hybrids, formed by layering ionic hydrogels (soft, stretchable, transparent and conductive materials in which ions carry charges as opposed to electrons in conventional electrode components) and silicone-based dielectric elastomers (a type of electroactive polymer) in succession. When layered in this manner, this hybrid material system results in a structure that replicates the skin’s dermal and epidermal layers. While these materials have been researched and developed for years, never before have they been subject to 3D printing for fabricating functional actuators, largely because of the postprocessing necessary to bond the hydrogel inks (which are hydrophilic, i.e. can be mixed with or dissolved by water) with silicone-based materials (which are hydrophobic, i.e. repel water).

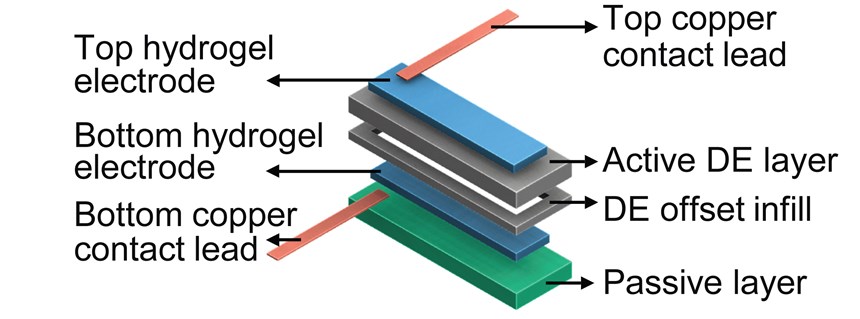

Haghiashtiani and her team applied a chemical treatment strategy on the silicone surface (with a solution including benzophenone photoinitiator), along with exposure to UV light, to create graft polymerization and chemical bonding between the hydrogel and elastomer surfaces. With this bonding between previously unprintable layers now possible, the research team was able to insert copper tape pieces as electrical contact leads into the device structure between layers as they were printed. The bottom electrical lead was inserted during the printing process before deposition of the hydrogel layer, while the top electrical lead was placed on top of the hydrogel layer after the printing was complete (see Figure 2).

None of this would have been achievable, however, without solving the other constraint to the printability of these materials: viscosity. (Or, to be more exact, the rheological properties of the materials, of which viscosity is a prime characteristic.) The extrusion-based printing process used for this study, direct ink writing, necessitated material characteristics that would decrease the viscosity of the inks as they flow through the deposition nozzle and become subject to higher pressures. This property is known as shear-thinning behavior. Through manipulation of the composition of both the hydrogels and the elastomer inks, Haghiashtiani and her team were able to optimize shear thinning behaviors specifically for their printer’s nozzle tip diameter, extrusion pressure and printing speed used in the UofM lab.

The printers themselves are custom-built devices that employ a gantry system along with a deposition-based robotic fluid dispenser made by Fisnar. The machines were originally housed at Princeton University, where this study’s principal investigator, Prof. Michael McAlpine (now at UofM) performed extensive research in 3D printing active materials.

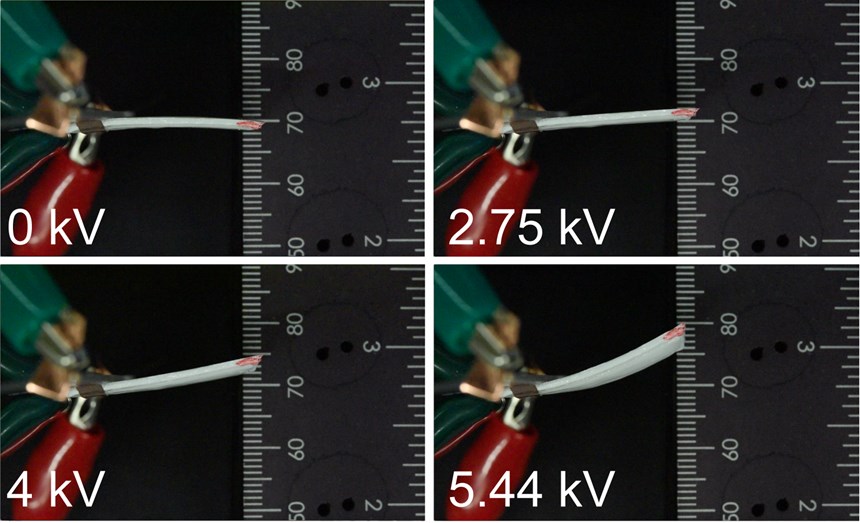

For Haghiashtiani’s study, the finished test device consisted of several layers, including, from bottom to top, a passive layer with a bottom electrode placed on top, followed by the dielectric elastomer, topped by another electrode. On this device, the team conducted performance tests across several conditions to measure the responsiveness to electrical stimuli, including step changes in applied voltage to the electrical leads (see Figure 3). “In a fundamental DEA configuration, when you apply electric voltage,” Haghiashtiani told me, “you are going to see that the dielectric elastomer expands in area, while its overall thickness shrinks. In the bending DEA, the stiffer passive layer imposes a restriction on the structure, resulting in translating the in-plane deformation to out of plane bending motion.”

In order to keep the two electrodes from coming into contact with each other and shorting the device, the team printed the hydrogel electrodes with an offset of 2 mm from each side on the corresponding passive layer and the dielectric elastomer layer. They added barium titanate nanoparticles to the silicone layer to enhance the overall electromechanical sensitivity of the device, and tested different applied voltages to measure the DEA performance in lifting small payload masses placed at the device’s tip.

...the path exists for someday 3D printing self-sensing, soft robotic systems that mimic the abilities of natural muscle, including neurons that “provide a sense of spatial position and motion.”

The results of these tests led Haghiashtiani to conclude that not only are 3D-printed soft dielectric elastomer actuators capable of generating movement and motion, but that the path exists for someday 3D printing self-sensing, soft robotic systems that mimic the abilities of natural muscle, including neurons that “provide a sense of spatial position and motion.” Partly because this research was conducted with the U.S. Army Research Lab, media attention paid to Haghiashtiani’s article was almost entirely focused on the potential military applications that this technology promises. News articles about the research often featured stock photos of octopuses and squids below headlines that claimed that the U.S. Army is building “squid-like” soft robots that can maneuver within confined and congested spaces. This may someday be possible, but these soft devices and stretchable electronics include mechanical energy harvesting devices, actuators, flexible circuit boards and electroluminescent skins—applications that could resonate in numerous fields.

That’s not to say that untethered mechanical systems and soft robots don’t hold distinct interest to the military. But Haghiashtiani sees other, perhaps shorter-term applications in the field of smart prosthetics. Still, there is work to be done. “Right now the level of voltage required to activate these devices is probably too high,” she says. “The voltage is at the kilovolt range, which is why there is reluctance to use this for medical applications in general. This work is just scratching the surface. Using this type of 3D printing for making soft actuators—there is more work that needs to be built upon this to improve the performance of devices and develop them into more complex structures that can be readily functional right off the printer.”

Related Content

Quadrus: Powder Management Tactics for Tungsten Rhenium and Other AM Alloys

The expert in additive manufacturing of high-value parts for the Defense Department often must change from one exotic material to another in its powder bed machines. Cleaning is a core competency. Here are lessons of this company’s system for working with an ever-changing mix of 3D printed alloys.

Read MoreBeehive Industries Is Going Big on Small-Scale Engines Made Through Additive Manufacturing

Backed by decades of experience in both aviation and additive, the company is now laser-focused on a single goal: developing, proving and scaling production of engines providing 5,000 lbs of thrust or less.

Read MoreThis Year I Have Seen a Lot of AM for the Military — What Is Going On?

Audience members have similar questions. What is the Department of Defense’s interest in making hardware via 3D printing over conventional methods? Here are three manufacturing concerns that are particular to the military.

Read MoreBig Metal Additive: The Difference Between a Shape and a Part Is Quality

Preparing to scale directed energy deposition to ongoing full production is not a technological challenge: DED is ready. But it is an organizational challenge, says the company founder. Here is what it means to implement a quality system.

Read MoreRead Next

3D Printed Polymer EOAT Increases Safety of Cobots

Contract manufacturer Anubis 3D applies polymer 3D printing processes to manufacture cobot tooling that is lightweight, smooth and safer for human interaction.

Read MorePostprocessing Steps and Costs for Metal 3D Printing

When your metal part is done 3D printing, you just pull it out of the machine and start using it, right? Not exactly.

Read MoreProfilometry-Based Indentation Plastometry (PIP) as an Alternative to Standard Tensile Testing

UK-based Plastometrex offers a benchtop testing device utilizing PIP to quickly and easily analyze the yield strength, tensile strength and uniform elongation of samples and even printed parts. The solution is particularly useful for additive manufacturing.

Read More