Realizing Efficiency and Sustainability Through Automated Postprocessing of Resin 3D Printed Parts

Workflow efficiencies and sustainability goals can be achieved together. An automated cleaning system and longer-lasting detergent allowed one manufacturer to reduce hazards, costs and time in its resin removal process.

As we continue into the new decade of the 2020s, environmental issues such as climate change and pollution loom on the horizon. A worldwide focus on shifting how we care for our planet means that companies hold a great responsibility to practice sustainable business models. In fact, the market more or less demands it. Consumers are becoming increasingly more likely to purchase from companies that are mindful of their impact on the environment and society. A 2019 HP study found that 61% of survey participants believe business sustainability is mandatory. Additive manufacturing (AM) can be more a sustainable production method in terms of its more efficient material usage than subtractive manufacturing, the on-demand production it enables, and the increase in localized manufacturing it helped to usher in during the COVID-19 pandemic. However, there is one aspect of additive manufacturing that can be a hurdle both to improving efficiencies and implementing more sustainable AM workflows: postprocessing.

Product development company Splitvision had been making strides toward improving its efficiencies by investing in a Figure 4 system, a photopolymer-style 3D printer from 3D Systems. The technology sped up production and enabled better mechanical properties and fine feature details, but the resin removal process bogged down employees with unpleasant working conditions, excessive manual labor and product inefficiencies. Additional concerns about the sustainability of the existing parts cleaning process with isopropyl alcohol (IPA) led the company to seek out a more environmentally conscious postprocessing alternative. The solution it arrived at is more sustainable and safer for employees, and is also bringing cost and time savings to the company as well.

Hazards of Resin Removal

Traditionally, postprocessing of 3D printed parts is a highly manual step that, depending on the printing technology, could involve hand-picks, razor blades, waterjets, sandblasters, hand sanding, dunk tanks and other outdated methods. Across the board, these postprocessing methods are time-consuming and especially laborious, resulting in an elevated risk of repeat-use injuries for technicians, and productivity inefficiencies in an otherwise streamlined workflow.

Of all of the postprocessing methods, resin removal is particularly notorious for being unsustainable thanks to its heavy usage of potentially hazardous chemicals. Photopolymer 3D printing technologies requiring resin removal processes include Digital Light Processing (DLP), stereolithography (SLA) and Continuous Liquid Interface Production (CLIP). To a technician operating a photopolymer additive manufacturing workflow, the shortcomings of typical resin removal solvents — such as isopropyl alcohol (IPA), dipropylene glycol methyl ether (DPM) or 1,2-trans-Dichloroethylene (1,2-DCE) — are obvious. In fact, in PostProcess Technologies’ 2020 Post-Printing Trends Survey Report, resin-based 3D printing users reported having the most concerns about safety in their post-printing operation of all 3D printing technologies.

The harmful fumes these solvents can give off have the potential to create a hazardous or, at the very least, highly unpleasant environment for technicians, while low flashpoints pose a fire hazard. Many of the solvents used in postprocessing also are or produce volatile organic compounds (VOCs). Similarly, a number of the solvents are unfriendly to aquatic life. From an environmentally conscious standpoint, utilizing hazardous chemicals requires more intricate safety, handling and disposal processes, as they can be generally more harmful to people, animal life and the environment.

Lukass Legzdins, R&D director for Splitvision, voiced sustainability and safety concerns for his team’s wellbeing associated with the IPA cleaning process, including the risk of repeat-use injuries from excessive manual labor. Citing the challenges with removing resin from intricate crevices like screw towers, small slots and ribs with IPA, Legzdins says, “It can be a very tedious job to fully clean the resin off of these features with a traditional solution like isopropyl alcohol. Even if the printer used is efficient and several parts can be manufactured in one run, the unit cost still does not go down much, since so much time is needed to clean each part individually. Apart from being time-consuming, the work environment also gets compromised by the strong smell from the IPA. Not to mention, we were always concerned about the fire risk posed by IPA.”

Automated Parts Cleaning

To mitigate these workflow and environmental concerns, Splitvision adopted an automated cleaning solution and detergent from PostProcess Technologies. The solution employs a blend of proprietary software, chemistry and hardware to transform workflows with automated support removal, resin removal, depowdering and surface finishing. Automating these processes enables optimal productivity, reduces the need for hazardous materials, and nearly eliminates the technician time and manual labor involved with postprocessing.

PostProcess’s resin removal chemistry formulations, as a part of its complex automated solution, was specifically developed as a more environmentally conscious, effective alternative to traditional solvents like IPA. The detergent serves as a critical asset of the full Submersed Vortex Cavitation (SVC) technology for automated resin removal. The technology employs ultrasonic cleaning, agitation and controlled temperatures in a vortex pumping scheme to remove resin quickly and efficiently.

More Efficient, Longer-Lasting Detergent

The PostProcess Technologies PLM-403-SUB detergent selected is overall less hazardous compared to a solvent like IPA. The nature of the detergent itself mitigates the combustion and inhalation risks that almost always concern resin removal users. The detergent’s vapor pressure at 20°C is 0.2 mm Hg, compared to IPA’s vapor pressure of 33.1 mm Hg. It is also less pungent, with an odor that’s been described as “sweet” and “ether-like” as opposed to the overpowering fumes of IPA. The detergent is considered nonflammable with a flashpoint of 220°F (104.4°C) and does not pose a fire risk, while IPA is categorized a flammable liquid with a flashpoint of 53°F (11.7°C).

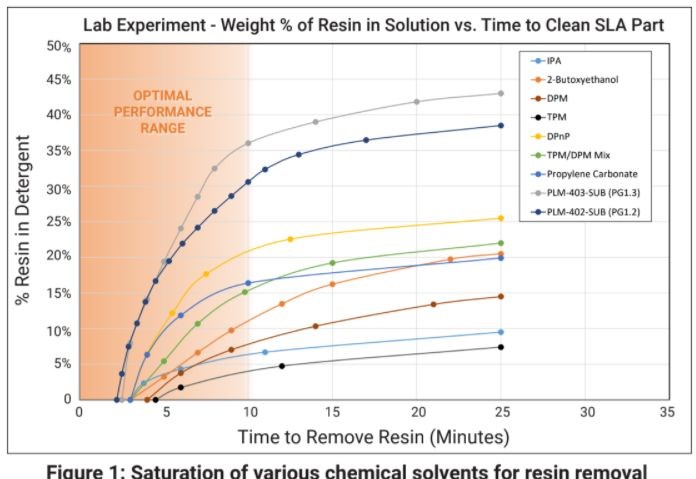

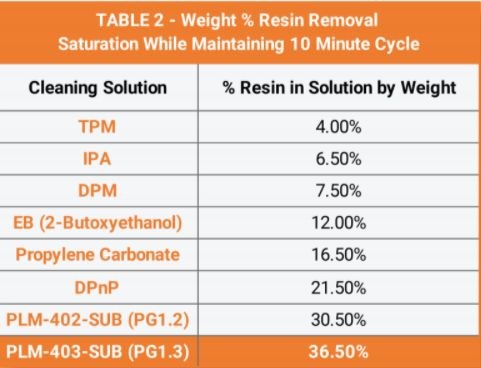

Perhaps most significantly in terms of sustainability, the detergent has outstanding longevity compared to most resin removal solvents. Longevity for resin removal detergent is typically defined as the amount by weight that the chemical solution can hold and still effectively remove resin. Most photopolymer 3D printing users seek to remove resin as quickly as possible, typically in 10-minute cycles or less. Therefore, longevity is compared at a 10-minute cycle time. From the data depicted in Figure 1 and in Table 2, the 403 formulation has significantly better longevity (capacity by weight of resin in solution at 10 minutes) than all other typical solvents used to remove uncured resin from printed parts (and specifically six times the longevity of IPA).

Figure 1: Compared to IPA and other chemical solvents used for resin removal, the 403 formulation carries a higher saturation of resin in a shorter amount of time. Image credit: PostProcess Technologies

Table 2: The 403 detergent can accommodate almost six times the amount of resin as IPA for the same 10-minute cycle time. Image credit: PostProcess Technologies

This longevity equates to more infrequent detergent changeouts which lessens machine downtime, creates a safer working environment and results in less chemical waste. Plus, once saturated with resin, 90%+ of this detergent by saturation weight (amount of resin in solution) can be recovered by distillation for reuse, which saves on disposal costs, produces less waste for disposal, and outright lowers waste and purchasing costs.

Cost, Workflow and Safety Improvements

Implementing the automated PostProcess solution for resin removal was not only beneficial to the Splitvision workplace safety and sustainability efforts. The solution has also enabled the company to cut postprocessing times down from 30 minutes per part to 10 parts in under 5 minutes. These time savings have enabled Splitvision’s staff to spend their workdays on more value-adding tasks, and put their minds at ease thanks to the elimination of workplace safety risks.

Speaking to the work environment benefits enabled by making the switch, Legzdins says, “We can now offer printed parts at a reasonable price, especially when printing multiple items in one run. Plus, the nasty bit of the printing process has been eliminated for our staff. The PostProcess solution was able to really streamline our post-printing process and improve workplace safety overall. It’s hard to imagine ever going back to using IPA.”

About the Author

Dr. Matthew Noble

Dr. Noble earned a doctorate at the University at Buffalo and has 25 years of experience as a chemist. He drives the development of additive-specific post-printing solvents as PostProcess Technologies' lead chemist.

Related Content

Sustainable Metal Powder Company Addresses Next Piece of Road Map: Renewable Energy

Continuum Powders, the material production arm of small-scale foundry technology company MolyWorks, has announced new partnerships aimed at further reducing the environmental impact of its metal powder production.

Read MoreOnAdditive Offers Aftermarket Upgrade for 3ntr A2, A4 3D Printers

The enhanced capabilities include a new control system that gives the printers increased printing speeds, improved quality, automatic bed leveling and various other user-centric improvements.

Read MoreEvaluating the Printability and Mechanical Properties of LFAM Regrind

A study conducted by SABIC and Local Motors identified potential for the reuse of scrap reinforced polymer from large-format additive manufacturing. As this method increases in popularity, sustainable practices for recycling excess materials is a burgeoning concern.

Read MoreHow Production Looks Different for 3D Printed Furniture Manufacturer Four Years Later: AM Radio #50

Furniture manufacturer Model No. has shown that there is a demand for customizable, sustainable 3D printed tables, chairs and more since we last covered the company in 2020. But today, production looks different.

Read MoreRead Next

Automated Postprocessing Speeds Resin-Based Additive Manufacturing Workflows

Two manufacturers utilizing resin 3D printing techniques have found time and cost savings via automated resin removal and part cleaning equipment.

Read MoreThe Link Between 3D Printing, Surface Finish and Mold Tools

Surface finish for 3D printed mold tooling has a direct effect on the pull-out force needed to remove the final part. Why molders should consider tool roughness along with geometry and materials.

Read MoreWhat Is Vat Photopolymerization?

Vat photopolymerization was the first AM process to be successfully commercialized. Three decades later, this technology has shown how AM is capable of scaling to volume production and making custom products on demand.

Read More