PolyJet Process Speeds Injection Mold Prototyping

By 3D printing prototype mold tools, German moldmaker Hans Geiger Spritzgießtechnik reduced both the time and money required to produce them.

Injection molding tools have to withstand enormous loads, necessitating the use of strong, highly resistant metals in production and requiring an expensive and time-consuming manufacturing process. This is not a problem for mass production of injection-molded parts, as thousands of operations mean investment costs pay off shortly, but the fixed costs involved and time required to produce mold tooling are out of proportion for small batch sizes or individual pieces. As an alternative, Hans Geiger Spritzgießtechnik has been exploring 3D printing for the prototyping of molds and plastic parts, resulting in significant advantages for both the manufacturer and its customers.

Part of the Geiger Group, Hans Geiger Spritzgießtechnik is a moldmaker and injection molder of plastic parts in Nurnberg, Germany. Previously, manufacturing prototype injection mold tooling at the company took several days, a process that 3D printing has shortened to six hours. “That significant reduction in time has made it much easier to test whether an object can actually be injection molded as planned,” says Geiger Process Engineer Hans Kolb. Consequently, Geiger can quickly test whether an injection molded part made with a prototype mold is fully functional or if any improvements are necessary. This means that parts made this way can be tested for their functionality, making it also possible to choose a design and materials early on. With the accelerated process comes a greatly reduced financial risk.

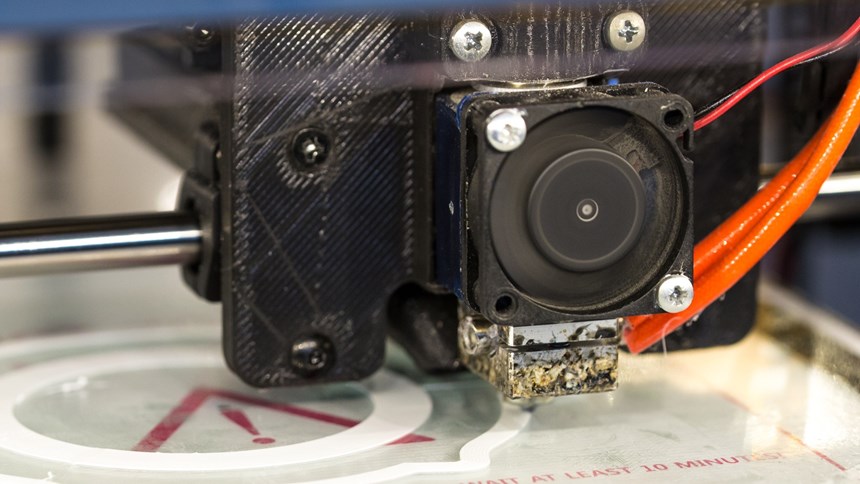

The company is using PolyJet 3D printing technology from Stratasys to create prototype injection molds without the milling and hardening steps that would be required to machine this tooling from metal. First, tiny droplets are sprayed onto a building platform and crosslinked via UV light. “We use synthetic resin for printing. The best results have been achieved with Digital ABS, especially for complex geometries,” explains Kolb. Following the UV curing, the support material is removed in a water bath or with a jet of water. If necessary, the printed workpiece is reworked by hand.

The prototype mold components can be used directly from the 3D printer with no post-curing necessary, generating less waste than milling, cutting or casting, which keeps material costs down. Components ranging to 165 cm3 can be printed, and the precision of the prints is about 1/10 mm. “Not every little detail can always be accurately represented; occasionally you have to reprocess a part mechanically,” Kolb says. “But for prototypes, the focus is not primarily on exact details, but on the option of testing different solution procedures.”

In principle, 3D printing can be suitable for all thermoplastic injection molding tools, but it may be advisable to reinforce the tooling in part with steel or aluminum. The company’s injection molding machines suitable for testing 3D-printed tooling range between 100 and 800 kN in clamping force. “Certain concessions to draft angles, radii or geometry of the parts may need to be made,” Kolb says . “After all, these are prototypes that are produced for testing and with a focus on low cost and fast manufacturing, not durable tools.” Depending on the material used, the prototype molds last about 20 cycles.

“If a tool does not meet the manufacturer’s expectations, the manufacturer has not invested large sums of money and valuable time, but can use this knowledge to make immediate improvements to the product—and re-test it a little later thanks to 3D printing,” Kolb says. According to him, this means faster processes with reduced risk, an encouraging development for the industry. The company says that by eliminating milling and hardening from the process, the user reduces the amount of time to produce a prototype from days to hours, 90 percent improvement. This lowers the cost of producing a prototype by as much as 70 percent, reducing the financial risk involved in prototype manufacturing.

Related Content

4 Ways Augmented Reality and 3D Printing Intersect

Augmented reality (AR) is bringing benefits to additive manufacturing, and vice-versa.

Read More3D Printed Tennis Racket Serves a Collaborative Win

The collaboration between All Design Lab and Protolabs led to the creation of a 3D printed tennis racket via direct metal laser sintering, called Hìtëkw. This project not only pushed the limits of additive in terms of design capabilities but revealed how important active communication between customer and manufacturer can be for a project’s success.

Read MoreFaster Iteration, Flexible Production: How This Inflation System OEM Wins With 3D Printing

Haltec Corp., a manufacturer of tire valves and inflation systems, finds utility in 3D printing for rapid prototyping and production of components for its modular and customizable products.

Read MoreAdditive Manufacturing's Evolving Role at Fathom Now Emphasizing Bridge Production

Bridge production is currently the biggest opportunity for additive manufacturing, says Fathom Manufacturing co-founder Rich Stump. How this service provider leverages AM while finding balance with other production capabilities.

Read MoreRead Next

3D Printed Polymer EOAT Increases Safety of Cobots

Contract manufacturer Anubis 3D applies polymer 3D printing processes to manufacture cobot tooling that is lightweight, smooth and safer for human interaction.

Read MoreCrushable Lattices: The Lightweight Structures That Will Protect an Interplanetary Payload

NASA uses laser powder bed fusion plus chemical etching to create the lattice forms engineered to keep Mars rocks safe during a crash landing on Earth.

Read MorePostprocessing Steps and Costs for Metal 3D Printing

When your metal part is done 3D printing, you just pull it out of the machine and start using it, right? Not exactly.

Read More