Machine Learning for Invention Will Aid and Be Aided By AM

Neural networks that learn by trial and error—learning, in fact, like a child—will map the constraints of AM systems, allowing part designs to be optimized for those systems.

Share

Editor’s note: We recently published a series of articles documenting how machine learning is being applied to additive manufacturing. Here is the introduction. Here are various applications already succeeding with machine learning. The article below, originally published in Modern Machine Shop, describes how machine learning is being applied to automate invention. But as you will read, this development, too, comes right back to additive manufacturing.

Neural networks are not scary.

Or so says Conrad Tucker, associate professor of engineering at Penn State University. Neural networks—artificial intelligence (AI) systems using advanced computing to aid in problem-solving—are tools that will eventually become accepted and widely employed by engineers. He is part of a team of researchers that recently won a $900,000 grant from the U.S. Department of Defense for a project that will train a computer system to invent. If this work realizes its aim, it will impact manufacturing because of the role manufacturing plays in invention.

Granted, if you need to claim something isn’t scary, then it must be kind of scary. But Dr. Tucker points out that we already interact with neural networks routinely. When our search engine returns give the web page we are looking for even after we mistyped the term, or when suggested purchase items on Amazon are eerily accurate to our tastes, this is the work of a neural network. Why can’t engineers use this same kind of network to obtain engineering designs that are eerily close to the optimal solution to a given problem?

The name of the project describes what it will do. GANDER aims to use “Generative Adversarial Networks for Design Exploration and Refinement.” The “adversarial” networks here are a generator and a discriminator. As the “generator” network proposes engineering ideas, the “discriminator” network shoots them down based on their fitness for physical reality. The generator then employs machine learning to grow from this feedback. Eventually, the generator will become so good at passing the discriminator’s reality tests that it will propose engineering designs that represent very effective solutions.

All the steps in realizing this vision are huge, because machine learning works through a mind-bogglingly large volume of data and calculations. Thus, the hope of automatic design is still a way off. Step one is to train the discriminator, and the grant funds this work. Many, many CAD models will be fed to a system that computationally subjects these part forms to a range of simulated physical environments to gage how the forms respond. Charting a comprehensive map of physical reality in this way might seem daunting, but Dr. Tucker says we have seen this kind of mapping before. Indeed, he lives with an active neural network that isn’t scary at all, but endearing.

“I have an 18-month-old son,” he says. “He is learning all about the world by exploring and testing it, and in part, he relies upon me to give him feedback. This is the same model at work: one agent generating ideas and the other agent constraining them.” Our computers can now follow the same model because they can now carry out the computations required at a useful speed.

The most immediate practical implications are liable to connect to additive manufacturing, Dr. Tucker says. 3D printing can help speed the networks’ learning by generating proposed forms for testing physically. And as part of mapping reality, the discriminator can map the constraints of the different 3D printing systems in order to propose designs that are optimized to these systems.

But the broader change for manufacturing will come in the way we invent. Today, we find our way to engineering solutions in much the same way as Dr. Tucker’s son, through physical exploration. We call these explorations “prototypes,” and a considerable share of the work of manufacturing is prototyping in some fashion. But in the future—maybe the far future, or maybe in 10 years—much of this work will be done computationally, with AI helping us to more quickly understand which ideas are ready for production.

Related Content

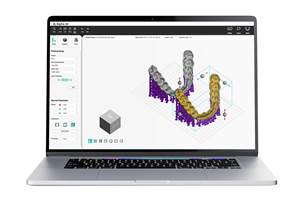

Vixiv Developing AI Alternative to Generative Design

Newly opened Ohio facility is where geometric cells are made and tested to inform the machine learning system that will “know,” without computation, what 3D printed form satisfies a given set of needs.

Read MoreSiemens’ Engineering HEEDS AI Simulation Predictor Optimizes Additive Manufacturing

The HEEDS AI Simulation Predictor empowers organizations to take full advantage of the digital twin to optimize products through advanced state-of-the-art artificial intelligence with built-in accuracy awareness.

Read More5 Observations From Dr. Tim Simpson About the State of Additive Manufacturing So Far

The outgoing co-director of Penn State’s CIMP-3D takes stock of how far AM has come, aided in no small part through the work of the organization he helped to lead.

Read MoreAI-Assisted 3D Slicing Software Simplifies Dental 3D Printing Process

The software simplifies the 3D printing process so users don’t need special design training.

Read MoreRead Next

How Machine Learning Is Moving AM Beyond Trial and Error

A Colorado alliance has found the link between AM and AI. Using machine learning to map the formula for successful metal 3D printing, researchers aim to know the right parameters for any new part with few or no test builds.

Read MoreWhat GE’s Machine Learning Ecosystem Will Mean for Additive Manufacturing

At GE’s Global Research Center in upstate New York, engineers join forces to build a digital library of additive research.

Read MoreHow Avid Product Development Creates Efficiencies in High-Mix, Low-Volume Additive Manufacturing

Contract manufacturer Avid Product Development (a Lubrizol company) has developed strategies to streamline part production through 3D printing so its engineering team can focus on development, design, assembly and other services.

Read More