The ADAPT Center at the Colorado School of Mines is a research facility housing at least $6 million worth of technology that is being dedicated toward realizing the full promise of additive manufacturing (AM). And that technology includes precisely zero additive manufacturing machines.

Machines are missing because printing parts is not the challenge the industry supporters of the ADAPT Center face. ADAPT is the Alliance for the Development of Additive Processing Technologies, a Colorado-based partnership of businesses together with academic and public institutions all cooperating to advance AM. Printing parts is something the individual members of ADAPT already know how to do—they either have the capability or have access to it.

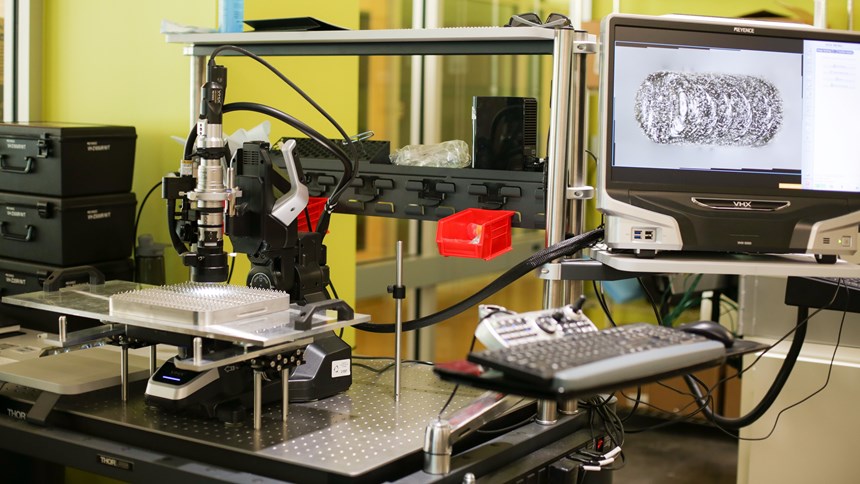

Instead, the center employs technology such as fractography, X-ray diffractometry, tensile testing and computed tomography. Rather than printing parts, the capabilities of the center recognize that perhaps the greatest challenge standing in the way of the advance of additive relates to understanding just what is going on inside those 3D-printed parts.

And this is a big challenge. AM is a manufacturing process like no other, because in an additive build, both the part’s outer geometric form and its internal material structure are created at the same time. In powder-bed fusion of a metal part, while the form is controlled by the path and intensity of the laser, the design of the support structures, the orientation of the part and various other factors, the list of variables potentially affecting the material structure—or affecting both outcomes simultaneously—is even more extensive.

Branden Kappes co-directs the ADAPT Center along with Aaron Stebner. When he tried to name just some of the variables germane to an additive build, he rattled off a list that taxed both his memory and breath. The form, material properties and integrity of a given metal part produced in a powder-bed process are potentially affected by, Kappes says, “Laser power, laser speed, laser spot size, pass overlap, composition of the powder, melt point and boiling point of various powder constituents, powder flowability, how many times the powder has been recycled, the percentage of contaminants, the speed of the recoater blade, the thickness of the part at any location, the resulting microstructure, the pressure of the shielding gas…” and his list trailed off at this point, not because he couldn’t think of more, but because he was beginning to think of factors too subtle to name concisely within a list like this. And powder-bed is just one method of making additive parts.

In short, in any AM build, there is a lot going on.

Which is why, to date, the successful users of additive manufacturing have dealt with the range of significant variables essentially through brute force—through extensive trial and error to get to a process that works. Proceeding through a long series of failures, they find a process that can reliably produce their part, then they lock in on the process for that part in a given material on a particular machine (and they frequently keep the details of this hard-won process secret).

The extensive physical trial and error is not the way forward, Kappes says. The way forward instead is to understand, to know in advance how the many variables do interplay.

Or more specifically, to know in advance the answer to this question: For the part I want to build, for the material structure best suited to the function I want the part to perform, what are the machine parameters and the process choices that can get me this result with little or even no trial and error?

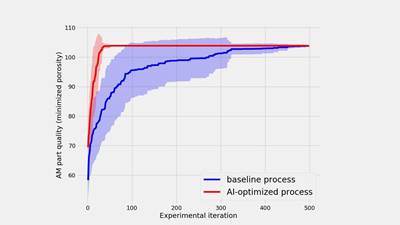

The variables figuring into that question are certainly too numerous to understand from experimentation alone, and hopefully the choice of materials will eventually be too numerous as well. That is why, importantly, the equipment in the ADAPT Center represents only a portion of the resources vital to the work this center has undertaken. An equally significant portion consists of mathematical resources. Machine learning is being used to extract the important findings from the data being gathered in the ADAPT Center’s work. And machine learning is guiding the research itself, determining what additive builds and what measurements are truly necessary to the ongoing refinement of this model so that, for example, attaining mastery over a single AM material such as Inconel 718 can be the work of a year rather than the work of a decade or more.

We have not yet quite awakened to the extent to which big data will play an instrumental role in additive manufacturing, Kappes says. We will.

And one long-term implication he sees—since few companies could cultivate all the machine-learning-produced algorithms they might need acting independently, or even feed enough data on their own to maintain these algorithms—is that the very relationships between manufacturing companies will change. Additive is a process like no other that will produce a manufacturing space like no other. Cooperation will be key, he says. And in his corner of Colorado, with the founding and growth of the regional alliance that led to his center, he believes this evolution might have already begun.

Too Big for Faustson

That regional alliance, ADAPT, started with a question that was asked by a machine shop. Or, more accurately, two questions.

The first question was: What capability will we need to have in five years in order to remain relevant and valuable to customers?

Faustson Tool, a Denver-area machine shop serving the aerospace and defense sectors, asked that question of its customers in 2014. The small shop was accustomed to taking a long view. An investment the 15-employee company made in five-axis machining in preparation to take on some challenging parts from Lockheed Martin led to an ongoing increase in work from that customer, but it culminated in a full-scale production order of five-axis parts fully 15 years after Faustson had made the five-axis commitment.

To the question about which capability it should turn its long view toward next, company vice president Heidi Hostetter said the answer from practically every customer asked was “additive manufacturing.”

So the question Faustson asked next explored what was missing from AM. The company asked, essentially: What could make additive a viable production option that would open the way for Faustson to provide production parts using this capability?

Hostetter says the seed of the answer came from Lockheed Martin Senior Research Scientist Craig Brice. The piece really no one was figuring out was arguably the most important piece for aerospace. The outer geometry of an additive part can be realized through the 3D printing itself or through postprocess machining, but what can be done to reliably control the microscopic geometry of the part’s material? He says this is the question that will ultimately shape how far metal additive manufacturing can go in providing critical parts to the aerospace industry and others.

And it was a question too big for Faustson alone. Upon recognizing this, another small, independent manufacturer might have turned away, but an important moment for AM in this part of Colorado occurred when Faustson chose a different way. Hostetter and Faustson president Alicia Svaldi began to look for allies.

That is, they began to work connections to put together ADAPT, and then the ADAPT Center. The $6 million for the center was the total of $2 million in grants from the Department of Defense matched two-to-one by industry contributions. Faustson also installed its own metal AM machine from Concept Laser, and set about spending its first year with this machine on making test pieces for the center to evaluate.

Machine Learning in Action

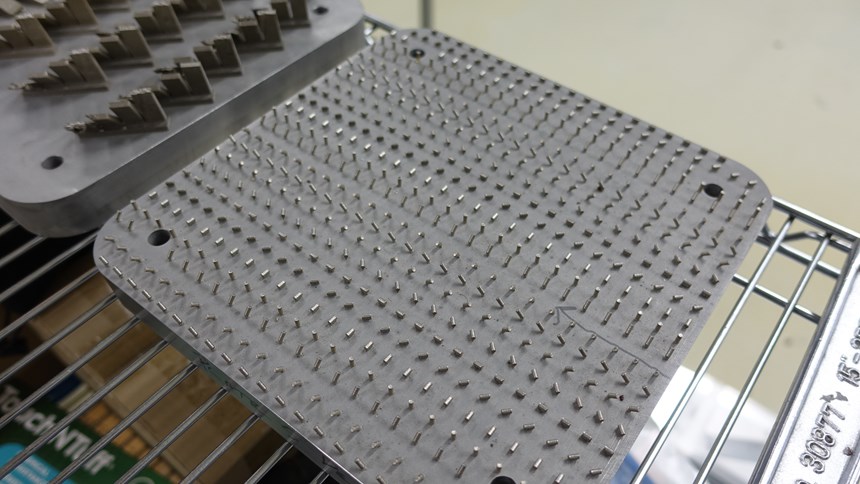

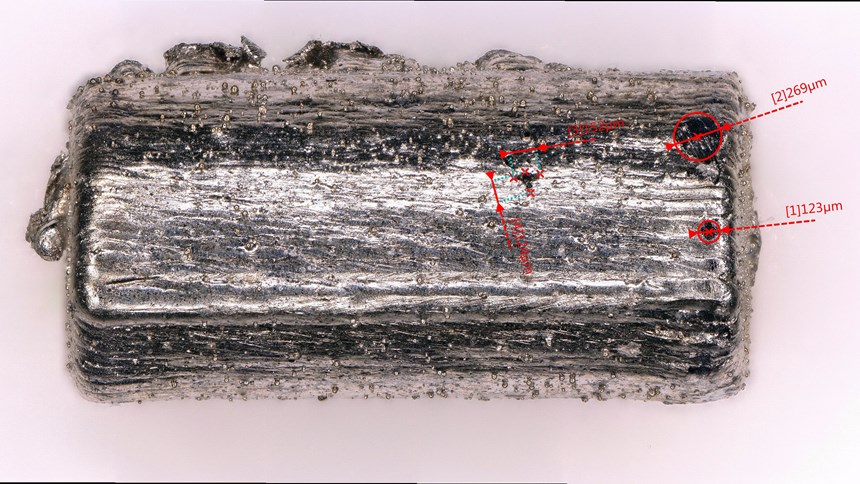

An example test piece—actually hundreds of test pieces—can be seen in the second photo above. The build plate shown has Inconel 718 test cylinders that are not only 3D-printed at various orientations, but also made using various orientations and settings of the laser. According to Kappes, Mike Muessel of the Faustson team is “a saint” for the programming work that went into the most elaborate build plates like this one. Laser settings and other parameters of the build had to change frequently at precise moments of the build to form the different cylinders using different, precisely defined parameter sets. By studying measurements of all these cylinders with various sophisticated tools, the center is exploring and documenting the effects of not only individual build parameters but also the ways combinations of parameters work together.

Machine learning is the means of finding these effects and finding their causal relationships. According to Bryce Meredig, chief scientist and co-founder of machine learning software developer Citrine Informatics (a bit more on this company below), machine learning can be thought of as a way to train a computer using examples. Where a conventional computer program executes a defined set of instructions, machine learning consists of algorithms that aim to find usable patterns in data. These patterns are used to build predictive models, which are incrementally refined through comparisons with real data. In a problem in which the number of inputs and outputs number in the tens, human beings working by experiment can find these predictive relationships. But where the number of inputs and outputs number in the hundreds or thousands, machine learning offers a means of finding what those data reveal.

Through machine learning, the existing data can be analyzed to determine precisely what further test parts are needed to make the predictive model more confident.

Dr. Meredig refers to the capability using the term “artificial intelligence,” but he uses the term as much to describe the capability’s limitations as its power. The AI still needs “HI,” the human intelligence, he says. Artificial intelligence or machine learning can take one billion possible relationships among a given data set and narrow them down to the ten or twenty that are potentially strong, but then human discernment and intuition are needed to determine which two or three of those ten or twenty are really worth exploring.

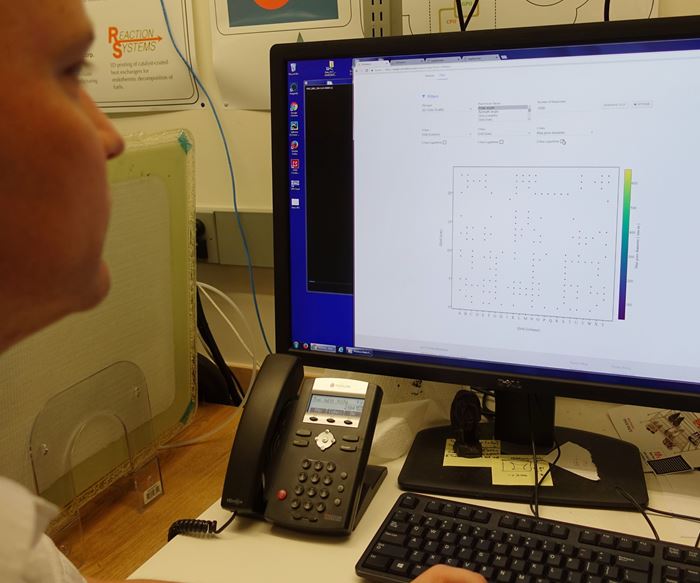

The data and the findings resulting from analyzing the data in this way are already paying off. Here is an illustration of how that is playing out, and how the knowledge the ADAPT Center has developed can be used: Assume an ADAPT member needs to additively produce a component in Inconel 718, and one of the critical requirements is that the maximum allowable internal defect size is, say, 90 microns. A model based on the many Inconel 718 test pieces that have been analyzed so far can predict parts’ maximum pore sizes for given sets of parameters. Indeed, the first photo at the top of this article shows the graphical interface for this prediction. The dots in the screen display seen here indicate where the mathematical model’s prediction is confident—that is, at which combinations of factors (including laser parameters, location on the build plate and orientation relative to the recoater blade) the model has a prediction that is statistically strong. For any outcome that is sought, the model might already be able to offer the set of process parameters able to win that outcome. But more likely, the outcome needed for a critical part will be so specific that the model as it stands will not be able to predict all the right inputs, yet will be able to with just a little further testing. Through machine learning, the existing data can be analyzed to determine precisely what further test parts are needed to make the predictive model more confident. That is, instead of a trial-and-error process involving anywhere from 20 to 50 iterations (that is, 20 to 50 builds of the part), the process likely can be proven with only three or four such iterations because the model can tell where the model itself is weak.

This kind of analysis required expertise beyond what ADAPT possessed when it was founded. The additive alliance discovered it needed a computational partner—a partner for the machine learning or the AI. The partner the alliance members found is the previously mentioned Citrine informatics. Based in Redwood City, California, this ADAPT member exemplifies how the alliance now extends past its Colorado roots. This firm is also a non-manufacturing member—except, as the very need to involve Citrine makes clear, additive expands the scope of disciplines needed to realize its promise. Machine learning is now being revealed to be a valuable manufacturing-related capability after all.

Pooling Knowledge

So far, the investigation in search of a predictive model for AM has focused on Inconel 718. And so far, test parts have been built on Faustson’s Concept Laser machine. As a result, ADAPT members have access to a model that can describe the behavior of this alloy on this platform. The members are well ahead on any need for trial-and-error within this context, but only in this context. The model obviously needs to be bigger than this. Kappes says there will be other metals investigated this same way, and other machines. And just making the model bigger will make it stronger.

Seemingly fundamental differences in the machine and the material will provide the chance for the model to find commonalities, even generalities, in the form of process parameter choices that extend from metal to metal and from machine to machine, he says. Already, the ADAPT Center has done some work studying AM parts made on the Sciaky machine employed by alliance member Lockheed Martin. This is a directed energy deposition (DED) machine (not powder-bed fusion like the Concept Laser) that uses an electron beam (not a laser). And yet, says Kappes, both machines are melting metal. Obviously the machines will differ in their responses to various inputs, but there will also be real power in discovering how their responses are the same—and how discoveries in the mathematical model around one platform might lend strength to the model around another.

Big data will benefit additive manufacturing, he says, because the AM process is inherently so complex. Indeed, big data will provide a vital advantage to AM users able to tap into that data, but the data sets truly big enough to be useful will only be able to come from groups of manufacturers pooling their knowledge. The result might well be that AM is most successfully performed by manufacturing communities or networks that look very much like ADAPT, Kappes says—that is, very much like the alliance begun by Faustson Tool that allowed the center he now serves to be created.

Thus, the ADAPT Center, with machine learning, is modeling how best to apply AM. But before that, by drawing on their contact lists, the founders of ADAPT might have been doing the same thing. They are modeling—by means of their cooperation—what may prove to be the best way for additive manufacturing to advance.

Related Content

Hexagon Invests in Divergent’s Autonomous, Sustainable Manufacturing

The Divergent Adaptive Production System (DAPS) is a fully integrated software and hardware solution, creating a complete modular digital factory that combines AI-optimized generative design software, additive manufacturing and automated assembly to build lightweight automotive parts and frames.

Read MoreLessons in Personalized Production From the 3D Systems Surgical Guide Process

Tailor-made manufacturing is one of AM’s richest possibilities, but the success factors inevitably draw on more than AM.

Read MoreActivArmor Casts and Splints Are Shifting to Point-of-Care 3D Printing

ActivArmor offers individualized, 3D printed casts and splints for various diagnoses. The company is in the process of shifting to point-of-care printing and aims to promote positive healing outcomes and improved hygienics with customized support devices.

Read More5 Observations From Dr. Tim Simpson About the State of Additive Manufacturing So Far

The outgoing co-director of Penn State’s CIMP-3D takes stock of how far AM has come, aided in no small part through the work of the organization he helped to lead.

Read MoreRead Next

With Machine Learning, We Will Skip Ahead 100 Years

Machine learning or AI will prove vital to the advance of AM. Computational power will enable additive to advance much faster than if it had been invented in an earlier time.

Read MoreA Public-Private Partnership Aims to Save Additive from Itself

Overwhelming process variables for metal additive manufacturing processes are derailing AM’s adoption for critical parts in aerospace. Colorado’s ADAPT Center—and its growing cache of data—is seeking common ground.

Read MorePostprocessing Steps and Costs for Metal 3D Printing

When your metal part is done 3D printing, you just pull it out of the machine and start using it, right? Not exactly.

Read More