Articles

The Rise of AM Factories, Metal 3D Printing, Machining Synergy and Favorite Stories from 2023: AM Radio #47

Additive Manufacturing Media editors reflect on the top 10 stories by pageviews and then share their favorites, regardless of ranking, in this podcast episode.

Listen3D Printing Brings Sustainability, Accessibility to Glass Manufacturing

Australian startup Maple Glass Printing has developed a process for extruding glass into artwork, lab implements and architectural elements. Along the way, the company has also found more efficient ways of recycling this material.

Read MoreTop 10 Additive Manufacturing Stories of 2023

Laser powder bed fusion, proprietary AM processes, machining and more made our list of top 10 articles and videos by pageviews this year.

Read MoreThis Drone Bird with 3D Printed Parts Mimics a Peregrine Falcon: The Cool Parts Show #66

The Drone Bird Company has developed aircraft that mimic birds of prey to scare off problem birds. The drones feature 3D printed fuselages made by Parts on Demand from ALM materials.

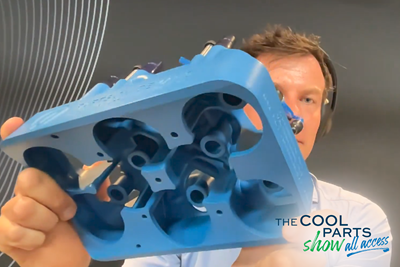

Watch3D Printing for Automated Food Packaging: The Cool Parts Show All Access

Parts on Demand CEO Neil van Es shows examples of 3D printed food automation hardware.

WatchAdditive Manufacturing for Defense: Targeting Qualification

Targeting qualification in additive manufacturing for the defense industry means ensuring repeatability as well as reliability as there is much at stake, including human lives. Certain requirements therefore must be met by weapons systems used by the defense industry.

Read MoreIntrepid Automation: How Investment Casting Benefits From High Speed DLP

Vat polymerization 3D printing for investment casting patterns offers a way to deliver design freedom at production speed.

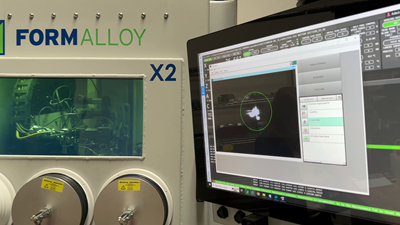

Read MoreMaking Sense of Data from Directed Energy Deposition (DED)

“It should be easier to qualify an additive part than a casting,” says Formalloy CEO Melanie Lang. The company’s tools for capturing and analyzing data are bringing this vision closer to reality.

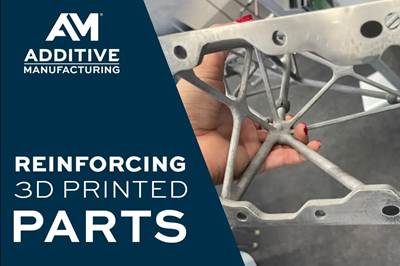

WatchVideo: Reinforcing (and Joining) Parts After 3D Printing

Reinforce 3D has developed a method that can be applied to strengthen 3D printed parts by feeding continuous fiber and resin through them. The technique also enables joining parts of various materials and manufacturing methods.

WatchNext-Gen Horse Trailers to Be Built With Robotic 3D Printing

Double D Trailers is currently developing a prototype horse trailer that will be made with large-format additive manufacturing. The technology brings potential benefits for labor, weight and design features to this subset of recreational vehicles.

Read MoreProtolabs Opens New DMLS Facility to Meet Increasing Additive Demand

Protolabs recently opened the doors to its new DMLS additive manufacturing facility to support its customers’ growing demand for AM. The facility, built from the ground up, was designed to accommodate a smooth and safe workflow, continue expanding machine and technology offerings and promote burgeoning additive production.

Read More3DOS, AeroEdge Collaborate for Decentralized Manufacturing in Japan

The aerospace manufacturer will be the first major industrial partner for metal additive manufacturing on the 3DOS platform for decentralized additive manufacturing.

Read More