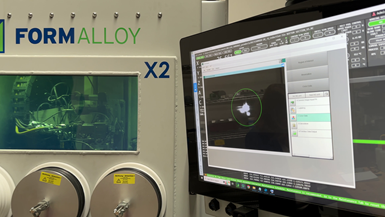

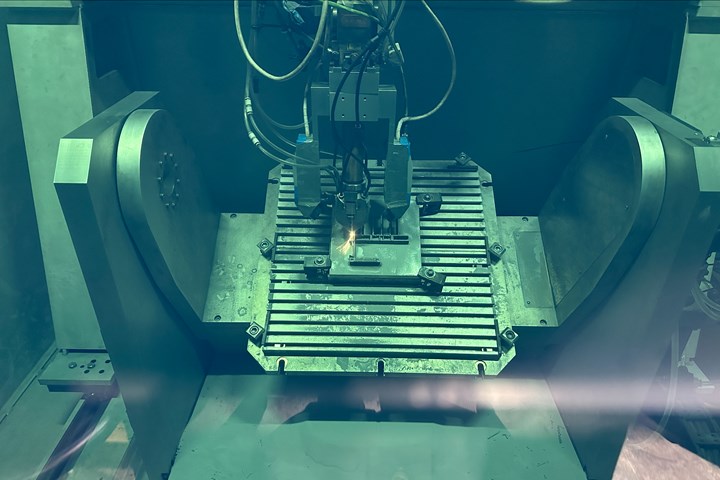

“There’s no one sensor that is going to be the key to unlocking the whole process,” says Melanie Lang. However, many sensors may be that key. Lang’s company Formalloy is arriving at a way of doing directed energy deposition (DED) that is inherently data-driven and controlled thanks to extensive use of sensors throughout the machines.

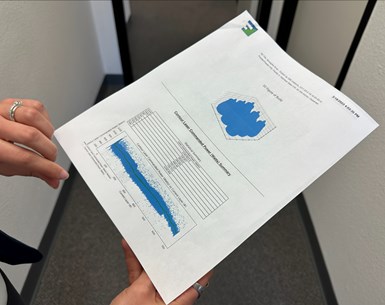

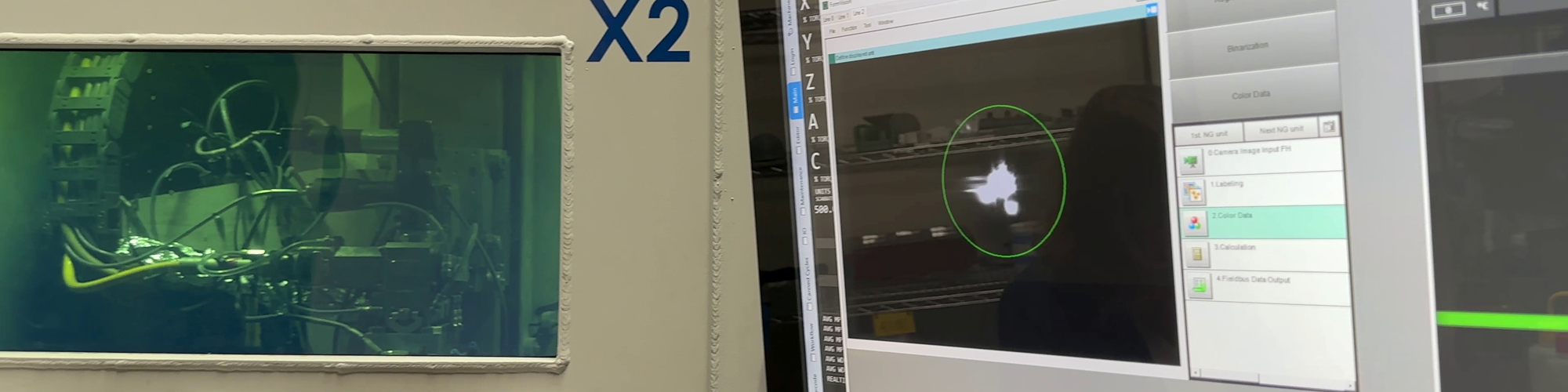

Within one of Formalloy’s powder- or wire-fed DED printers, sensors are monitoring the meltpool size, the laser power, even the temperature of the optical glass. All this information is captured and stored in its raw form, and also provided to the machine user or customer in a PDF with graphics. Additional data visualization and processing are also possible through the company’s DEDSmart software suite.

Additive manufactured metal parts often face greater scrutiny than conventional castings or forgings. Formalloy believes these parts should be more readily accepted, however, because a DED printer equipped with sufficient monitoring capability allows for gathering data about every step along the way.

These data capabilities have evolved along with the machines themselves. When I first visited Formalloy’s San Diego headquarters in 2018, the DED machine in use practically required a PhD to operate — not unlike many metal 3D printers at the time. A knowledgeable human technician needed to be standing by to monitor the state of the print and to quickly intervene when something appeared to be going wrong.

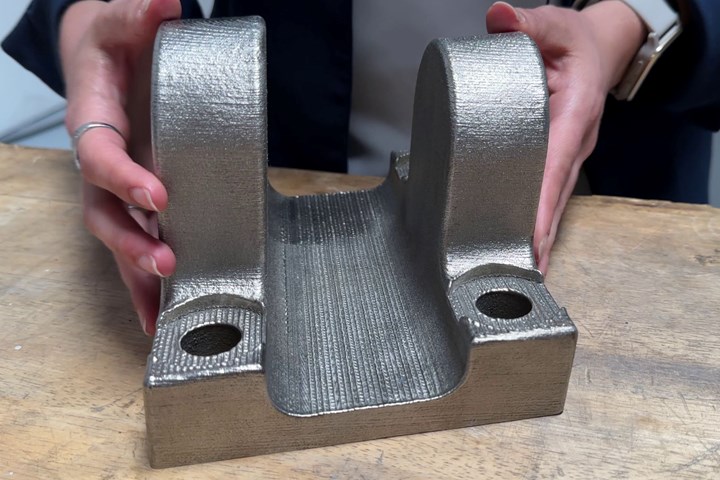

Melanie Lang (right) shows me some of the parts printed by Formalloy through DED. Since my prior visit in 2018, the company has expanded its physical footprint in San Diego, expanded its sensing and data gathering capabilities, and added wire DED to its portfolio.

“We’re past that now,” Lang says, describing the years-long process of sensor integration that involved interrogating that knowledgeable operator’s thought process for interfering with a build through questions such as:

What did you observe in the machine? What appeared to be happening with the part? What was the root cause?

From these observations emerged specific pain points that could be measured with sensors, tracked over time, and monitored with software. To borrow from the name of the company’s software package, the result is DED that is now, well, smart.

Monitor the Part and the Machine

But while putting brains into the machine was necessary at first just for the sake of controlling the process, all this data is now providing very real benefits for Formalloy customers and machine users. The company’s directed energy deposition printers excel at complex metal parts that can be up to 1 meter by 1 meter by 600 mm in its largest L-Series machine. A single print might take days to complete — posing significant risk should a defect form in the part. Sensors and data can not only detect when this is happening, but also help users make better decisions about inspection and other downstream steps.

Data from the 3D printing process is collected and can be visualized in a number of ways through DEDSmart, including an easy-to-reference PDF report.

In many cases additive manufacturers either find themselves inspecting every part, which is costly and time-consuming, or inspecting only a selection and assuming the rest are good, which leaves the door open for failures in those uninspected parts down the line.

Gathering data about a part point-by-point during DED serves as an early alert system for serious defects, as well as a way of targeting further inspection just to specific areas and parts that require it.

“You’re always going to have anomalies,” Lang says, “but if you know where those anomalies are, you can avoid situations where parts fail. It’s a more targeted way of doing inspection.”

Point-by-point data collection means that AM users can focus their efforts on specific part regions where anomalies have formed. It could be that such anomalies turn out to be innocuous or within spec, but they could also merit additional testing or scrapping the part altogether. That early alert saves time and cost, not only in printing and inspection, but also in any downstream postprocessing, as well as when the part is in use.

“Failure only gets more expensive the farther along you find the defect,” Lang says.

According to Lang, Formalloy’s sensing and data capabilities also make it possible to head off problems at the 3D printer, before they become part issues. One of the metrics tracked in DEDSmart, for example, is the temperature of the optical glass. If the glass stays clean, its temperature should remain stable. But if the optical glass becomes dirty, it will draw laser power away from the meltpool and see a spike in temperature. By monitoring this metric Formalloy can ensure consistent laser power at the meltpool and prompt the operator to clean the glass before it creates a larger problem in a part or the machine itself.

Data Answers Doubts

This type of data collection and follow-up has proven necessary for the kinds of applications that Formalloy and its customers see, where often 3D printing is being applied to replace a forging or a casting. For example, the company recently developed a wrecker bracket for the U.S. Marine Corps that was printed with Inconel powder in just a few days as an alternative to sourcing and machining a casting.

This wrecker bracket for the Marine Corps functions like a trailer hitch that pulls a multi-ton vehicle. The part was 3D printed from Inconel using Formalloy’s powder DED capability; the print was optimized for speed rather than surface finish, which accounts for the greater visibility of the layer lines.

In situations like this, end users recognize the benefits that AM can bring in terms of speed or other advantages, but often remain skeptical that a DED part can be a valid replacement. As a result, Lang has found that the additive part can face more rigorous requirements than a casting ever would.

“You can’t see what’s happening inside the mold of a casting so you could never ask if porosity formed in a particular region,” she says. “But with DED, we can see every layer. We can track what’s happening at every point. We know exactly how that additive part was formed.”

Formalloy has become more vertically integrated in its machine production over time. Its DED systems are built and tested at its San Diego headquarters, and demand is growing.

Acceptance can be an uphill battle, but the company has seen growing adoption of its DED machines as well as individual modules for powder and wire 3D printing, materials development and more (to the extent that it has had to become more vertically integrated in order to meet the demand for new machines, which are built and tested in its San Diego headquarters). Many systems are going into research facilities as well as to military, railroad repair and power generation clients — all spaces where freedom from castings or forgings can be beneficial.

“It should be easier to qualify an additive part than a casting,” Lang says. “We’re at the point now where it’s more of a people problem — a familiarity problem — than a technology problem.”

Related Content

Zeiss Hosts Digital Event for Metrology and Software April 15-19

The event is designed to offer a unique opportunity to gain new, interesting insights and exchange ideas with industry experts from all over the world.

Read MoreProfilometry-Based Indentation Plastometry (PIP) as an Alternative to Standard Tensile Testing

UK-based Plastometrex offers a benchtop testing device utilizing PIP to quickly and easily analyze the yield strength, tensile strength and uniform elongation of samples and even printed parts. The solution is particularly useful for additive manufacturing.

Read MoreVideo: Scanning for Fast Model Capture and Validation of AM Parts

3D printing offers a fast way to obtain a part. Can developing the printable file and validating the printed part be done rapidly as well? See fast measurement technology for complex 3D forms I found at IMTS.

Read MoreRenishaw and Plastometrex Collaborate to Increase Precision, Efficiency of AM Mechanical Property Analysis

Plastometrex’s PLX-Benchtop facilitates rapid, direct testing on different sections of additively manufactured parts, delivering comprehensive stress-strain curves in minutes to provide a more precise evaluation of a part’s mechanical properties.

Read MoreRead Next

Bike Manufacturer Uses Additive Manufacturing to Create Lighter, More Complex, Customized Parts

Titanium bike frame manufacturer Hanglun Technology mixes precision casting with 3D printing to create bikes that offer increased speed and reduced turbulence during long-distance rides, offering a smoother, faster and more efficient cycling experience.

Read MoreCrushable Lattices: The Lightweight Structures That Will Protect an Interplanetary Payload

NASA uses laser powder bed fusion plus chemical etching to create the lattice forms engineered to keep Mars rocks safe during a crash landing on Earth.

Read More3D Printed Polymer EOAT Increases Safety of Cobots

Contract manufacturer Anubis 3D applies polymer 3D printing processes to manufacture cobot tooling that is lightweight, smooth and safer for human interaction.

Read More

.jpg;width=70;height=70;mode=crop)