Share

Read Next

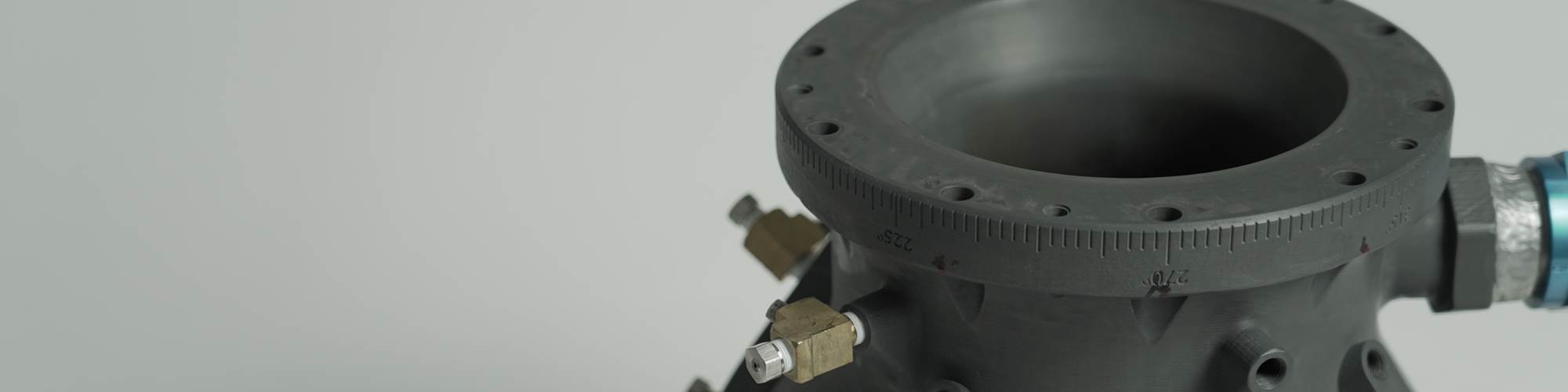

Masten Space Systems developed a lightweight, reusable rocket engine for NASA’s aim to fly repeated trips to the moon in rapid sequence with little delay between launches. The “Broadsword” engine was made using laser powder bed fusion by Elementum3D on a machine from EOS. Additive manufacturing (AM) enabled sophisticated internal cooling channels and the consolidation of the engine’s parts into just three major components, all 3D printed, including the combustion chamber seen in this episode.

AM also allowed for light weight through the choice of material. Rather than a high-temperature (and heavy) aerospace alloy, this chamber is made of a metal matrix composite developed by Elementum3D that combines aluminum for light weight with ceramic for high temperature performance. | This episode of The Cool Parts Show brought to you by Carpenter Additive

The Cool Parts Show is a video series from Additive Manufacturing Media that explores the what, how and why of unusual 3D printed parts. Watch more here.

Have a cool part to share? Email us.

Related resources:

- Masten Space Systems

- Elementum3D

- EOS

- 3D printed components for Mars

- 3D printed rocket fuel injector

- Metal matrix composite use for cars

Transcript:

Peter Zelinski

This part is going to the moon. We catch it before it launches on this episode of The Cool Parts Show.

Stephanie Hendrixson

The Cool Parts Show is brought to you by Carpenter Additive. The company's Athens Alabama Emerging Technology Center is an end-to-end additive manufacturing production facility with everything from materials development through post processing under one roof, ready to help you with your next metal 3D printing job. Check them out at Carpenter Additive.com. Now, back to the show.

Peter Zelinski

I'm Pete.

Stephanie Hendrixson

I'm Stephanie.

Peter Zelinski

Welcome to The Cool Parts Show.

Stephanie Hendrixson

This is our show all about cool, unique, amazing 3D printed parts, but Pete, I can't help but notice that the part we had here on the table during the opening is now gone. What happened?

Peter Zelinski

Well, we are about to talk about the 3D printed combustion chamber of the broadsword rocket engine for Masten Space Systems, we will bring the cool part right back up in a bit, but first we had this part with us for a very short period of time here in the studio. This was our first cool part to arrive with an escort. Do you want to talk about that?

Stephanie Hendrixson

Yeah, this combustion chamber is a valuable part, it is not like Masten just had an extra one that they could send us for a few days. So instead Elementum 3D, the company that did the 3D printing agreed to bring the part here to our studio, just so we could use it for a short period of time, but all that being said security detail aside, Pete, what is so cool about this part,

Peter Zelinski

The broadsword engine is a reusable rocket engine for repeated trips to the moon. It can do moon missions in rapid sequence with very little service in between. Masten Space Systems is going to the moon in 2022, they're going to be part of NASA's Artemis moon missions and Masten's role there will have to do with overseeing the lander that delivers payloads to the moon's South Pole. The broadsword engine is not part of that, but this part or one like it is headed to the moon eventually, NASA is funding the development of capabilities that will allow us to do repeated boon trips in the years to come, and as we're going to hear, additive manufacturing is just huge for this because it is allowing us to utterly reconceive our sense of what a rocket engine even looks like.

Stephanie Hendrixson

Alright, so we are going back to the moon, we are going to keep on going back to the moon, and we're going to get there a little bit differently than we have in the past. I think we are ready to talk about the additive manufacturing part of this. What do you think?

Peter Zelinski

Yeah, I think so. Let us cut to the conversation we had while we have the part with us.

Stephanie Hendrixson

Cue wardrobe change.

Peter Zelinski

I am excited to tell you about our part today. This is the combustion chamber for a rocket engine, it's made out of mostly aluminum, that is going to be significant. It is one of just three 3D printed pieces that make up this rocket engine pretty much in its entirety.

Stephanie Hendrixson

I am sensing a lot of kind of classic cool parts themes, I imagine we're going to talk about design, light weighting, maybe materials.

Peter Zelinski

That is right. Masten Space Systems sort of committed to additive manufacturing as the way to produce this engine, and that led to a lot of assembly consolidation. Just three major components of the engine, because it's additive, no fixed tooling, no fixed process. Masten Space Systems was able to iterate, and refine the design of this engine, and get it just right for the performance that they needed. Another thing 3D printing accomplished specific to this combustion chamber is the cooling channels, obviously can't be seen because they're intricate channels inside of this component, but 3D printing enabled these channels to be designed and printed into this really solid piece.

Stephanie Hendrixson

So, 3D printing is doing a lot here. There's that really rapid design iteration, the complex internal geometry with those cooling channels you just mentioned, and then you said that this is a three-part engine, and mentioned assembly consolidation. What is the difference between this and a more conventional engine in terms of part count?

Peter Zelinski

Yeah, a lot of difference. A rocket engine that's just three parts? A rocket engine ought to be hundreds of parts, particularly with the cooling channels, right? To create this part, to get all the cooling channels necessary on the inside, some kind of intricate assembly would be the only other way to do that. Build this network of channels, build the chamber walls around it, but that is not the case with this part which was made entirely in this solid piece. The material is also significant, and we are going to get to that, but first I want to bring in Matthew Kuhns of Masten Space Systems, and he will say a little bit more about this engine.

Matthew Kuhns, Masten Space Systems

The broadsword engine is a very interesting rocket engine, it's additively manufactured aluminum, which gives it an extremely attractive thrust to weight ratio. That makes it an efficient engine particularly as a reusable boost engine or as an upper stage engine. The broadsword engine was originally intended for Masten's XS-1 Zephyr vehicle, so vertical takeoff, vertical landing, and box wing design. Technically speaking, broadsword is 25,000 pounds of thrust. It is a dual expanders cycle engine, so it uses turbo pumps, and it's a closed cycle. It's designed to be reusable, so everything is tuned around being able to perform 10 flights in 10 days with no maintenance in between, that flows through the turbine cycles, and then it also influences what materials we use and what the design looks like.

Stephanie Hendrixson

Wow, 10 flights in 10 days. You said reusable earlier, but I guess I'm just now appreciating the rapid timeline and how little space there is for downtime and maintenance on something like this. I see how additive could be an advantage with the assembly consolidation we talked about, you just have fewer parts to deal with and to worry about. Are there other reasons to use additive here?

Peter Zelinski

Let's stick with the cooling channels for a sec, because being able to print the cooling system in this within a solid piece leads to all that assembly consolidation, as you say, but there are so many implications to that. Fewer parts mean a quicker build time, just fewer components to worry about, fewer components to go wrong, to have to be inspected, or repaired, easier maintenance, and more rapid turnaround time between missions. There is this whole new paradigm for space travel, for the way that it works, and it is being enabled by additive manufacturing. I want to let Matthew Kuhns talk a little bit more about these cooling channels.

Matthew Kuhns

So one other benefit of additive manufacturing and rocket engines is the ability to really tune the cooling channel geometry to get the highest performance possible by pulling the heat from the combustion chamber into the cooling fluid. So traditionally, rocket engine cooling channels are very rectangular, because they're constrained by the manufacturing processes or their tubes if you're braised wall construction, because again you're constrained by the manufacturing processes. We partnered with New Mecca International and Oak Ridge National Lab to look at how can we rethink the cooling channel design, and we started running test cases on some new evolving geometries to look at where potential improvements in some of the standard design processes were. We ran on the Titan supercomputer at Oak Ridge National Lab, and New Mecca helped us put together kind of dynamic evolving test runs. The geometries were able to morph themselves to cover a huge design space, and that was some very interesting work, which should lead to increased cooling performance on future rocket engines.

Peter Zelinski

The cooling channels alone were not enough Masten Space Systems wanted an aluminum engine for the lightweight, and with the cooling system they engineered they tried to hold the temperature down just low enough that they could operate within the temperature strength parameters that aluminum alloy would permit. A pure aluminum alloy wasn't quite able to do it, so Masten Space Systems needed a different choice of material.

Matthew Kuhns

Initially, we started to use broadsword with AlSi10Mg. It printed fairly well, but the shortcomings of the material were that it has a very low deformation temperature, so it starts to deform and lose structural strength at low temperatures, at least when you're talking about rocket engines. What we ended up settling on was a metal matrix composites with ceramic particles inside, this lowers the thermal conductivity of it, but provides a much better high temperature strength, which is exactly what we need in the in the rocket engine.

Stephanie Hendrixson

Okay, so earlier when you said mostly aluminum, that's what you meant. Aluminum that also has ceramic in it. That is how Masten Space Systems was able to create this lightweight engine that was also going to withstand the extreme conditions that it's going to be subjected to. So where did they find this material?

Peter Zelinski

The creators of the material, Elementum 3D, a company we're both familiar with, materials company specializing in additive manufacturing Elementum 3D has created metal matrix composite materials that combine metal and ceramic. Materials for use within laser powder bed fusion processes, and extreme conditions is right because Elementum 3D was involved in iterate, trying to find just the right material combination, just the right metal matrix composite composition, aluminum, and ceramic to deliver exactly the performance that this rocket engine was going to need. Here is Adam Plizzi of Elementum. 3D.

Adam Polizzi, Elementum 3D

The material that Masten Space Systems broadsword engine is not a pure aluminum, or a pure material. It is a metal matrix composite, utilizing ceramic reinforcement particles in the commercially pure aluminum matrix. It really is not even you're run of the mill metal matrix composite. The material uses Elementum 3D's patented reactive additive manufacturing, or better known as RAM. The process utilizes a blend of AM size micron scale reactive constituents in the metal powder, which allow for good flow ability in the powder bed process. We probably worked on the order with 100 different compositions plus or minus, including different RAM constituent ratios, different RAM compositions. In the end, the A1000 RAM 10 proved to have the balance of elevated temperature, strength, thermal conductivity, and other properties that were important in the design of the Broadsword Engine.

Peter Zelinski

Additive manufacturing makes it possible to apply that metal matrix composite, or at least apply it this way, this sort of complex and precise geometry. The melt pool within laser powder bed fusion is small enough that it allows the aluminum to fuse around the ceramic particles, resulting in this microstructure consistent throughout the material, and throughout a form like this. That assures the combination of the lightweight you get from aluminum plus the high temperature performance you get from ceramic.

Stephanie Hendrixson

Kind of the best of both worlds here. You just mentioned the process powder bed fusion, I am looking at this part, and this seems like a pretty big part for PBF. Can you talk more about how it was made?

Peter Zelinski

So, this is a cool part, and it is cool for so many reasons. We have talked about some of them, the assembly consolidation, the cooling channels, metal matrix composite material, and did I mention it's going to the moon? Another cool thing about this is the build itself is just wicked cool, because all three of the components of this engine are produced in the same additive build. Elementum 3D is the contractor making this set of parts, and they make it on an EOS 400 machine. Big laser powder bed fusion machine, and the build height is not quite tall enough, even on a big machine for this set apart. So what Elementum 3D had to do to get just enough clearance, they milled down the build plate to get it to get it lower, so they could get this tall, big build just inside the build envelope for this machine.

Stephanie Hendrixson

Not only have we gone from hundreds of parts down to just three, they are all three printed together and it just barely fits. I think I got this. This part is a combustion chamber for the Broadsword Engine developed by Masten Space Systems. This combustion chamber is one of just three 3D printed parts that make up this engine versus the hundreds that you would have otherwise. It is made of a metal matrix composites specifically an aluminum with ceramic fill. The material was developed by Elementum 3D who is also the contract manufacturer for this, and Elementum prints all three of the parts all together in one build in an EOS 400 powder bed fusion machine.

Peter Zelinski

That'll do it for this episode of The Cool Parts Show. Thank you for watching The Cool Parts Show.com is where you can find all our other episodes. We've done all of our other cool parts and in the description for this episode, we'll include links to our other space related episodes.

Stephanie Hendrixson

If you have a cool part you'd like to tell us about email us Cool Parts at Additive Manufacturing.media. Thanks for watching. Thank you to our sponsor Carpenter Additive. Listen to additive manufacturing podcasts, attend webinars and learn more at Carpenter Additive.com.

Related Content

Possibilities From Electroplating 3D Printed Plastic Parts

Adding layers of nickel or copper to 3D printed polymer can impart desired properties such as electrical conductivity, EMI shielding, abrasion resistance and improved strength — approaching and even exceeding 3D printed metal, according to RePliForm.

Read MoreVideo: 5" Diameter Navy Artillery Rounds Made Through Robot Directed Energy Deposition (DED) Instead of Forging

Big Metal Additive conceives additive manufacturing production factory making hundreds of Navy projectile housings per day.

Read More3D Printed Titanium Replaces Aluminum for Unmanned Aircraft Wing Splice: The Cool Parts Show #72

Rapid Plasma Deposition produces the near-net-shape preform for a newly designed wing splice for remotely piloted aircraft from General Atomics. The Cool Parts Show visits Norsk Titanium, where this part is made.

Read MoreDMG MORI: Build Plate “Pucks” Cut Postprocessing Time by 80%

For spinal implants and other small 3D printed parts made through laser powder bed fusion, separate clampable units resting within the build plate provide for easy transfer to a CNC lathe.

Read MoreRead Next

This Rocket Fuel Injector Is a Solid Part That Contains a Working Motor: The Cool Parts Show #1

Our new video series debuts with a look at a solid metal part made through additive manufacturing that was built with a motor embedded inside. The motor sealed within the part adjusts the rocket’s fuel mixture while the rocket is in flight.

Read MoreLighter, Better-Performing Brake Rotor From 3D Printing: The Cool Parts Show #27

Additive manufacturing with an aluminum/ceramic composite enables a brake rotor with one-third the weight and five times the heat transfer of a typical rotor. We talk to the inventor on this episode of The Cool Parts Show.

Read More3D Printed Parts on the Mars Perseverance Rover: The Cool Parts Show #23

The Perseverance parts made through additive manufacturing are extreme examples of lightweighting. We have replicas of the 3D printed parts that were sent to Mars.

Read More