Jabil, Fictiv Partnership Addresses Capacity Challenge of Distributed Manufacturing via 3D Printing

With additive manufacturing, production can be relocated quickly and performed at whatever site is ideal. But what about the capacity waiting for this shift? Relationship gives global producer access to “transactional” 3D printing.

“Distributed manufacturing is one of the promises of additive manufacturing, but as with many promises, the devil is in the details,” says John Dulchinos, vice president of 3D printing and digital manufacturing for Jabil, Inc.

Jabil will realize this promise; it is already starting to do so. The global manufacturing service provider with over 260,000 employees and 100 facilities has industrial polymer 3D printers capable of scale production — including HP Multi Jet Fusion machines and selective laser sintering machines from EOS and Farsoon — in five different facilities, three in the U.S., one in Singapore and one in Switzerland. Because production on these machines requires no tooling, just the digital file, production theoretically can move between these sites instantaneously. Production can therefore be performed in whatever site has open capacity or in whatever location is nearest to the end use. This is distributed manufacturing, and Jabil sometimes makes these rapid shifts.

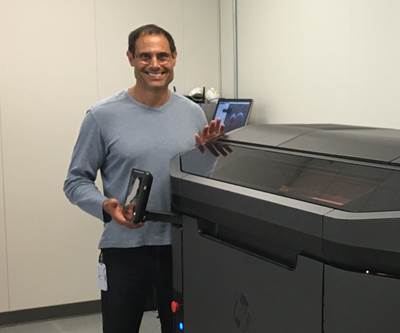

With Multi Jet Fusion machines such as these in multiple sites, including on separate continents, Jabil can shift work between them instantaneously. However, the capacity is too valuable to leave idle while it is waiting for this shift. Photo Credit: Jabil

However, here is the problem, says Dulchinos: Open capacity ready and waiting to receive a shift in production from a faraway site is … open capacity. On the one hand, distributed manufacturing needs this; it needs the margin in which to shift. Fully committed AM machines would leave no room for production to move. But on the other hand, a distributed manufacturing network can’t exist solely for the sake of the distributing. If every node is just waiting for the production that, say, serves its own geography, then the network would have capacity often sitting idle. If only there was a way for demand to flex in real time in the same way that location can now flex.

Enter Fictiv. Through an agreement with this company, Jabil leaders believe they have found the answer that can keep their additive manufacturing capabilities sufficiently utilized. Fictiv is a company that plays the role of manufacturing broker, accepting manufacturing jobs from buyers and seeing these jobs to completion by sending them out into a network of over 250 manufacturing partners. As of July 2020, Jabil joined as an additive manufacturing provider, becoming a major addition to this network. For Fictiv and the buyers of manufacturing work who use it, this deal offers increased 3D printing capacity, plus Jabil’s expertise as a contract manufacturer. For Jabil, this arrangement provides the company with a source of AM work to fill its available capacity without that capacity becoming too burdened for redistribution. That is, Fictiv provides access to work the major manufacturer is free to accept or decline at will, day by day, according the needs and openings of its AM machines.

“We think about different types of manufacturing business: strategic and transactional,” Dulchinos says. The strategic work is relationship-driven; Jabil serves as the manufacturing partner for an OEM advancing a far-reaching product line, and both companies invest for the long term. Not all manufacturing looks like that. The transactional work describes cases in which parts simply have to get made, whether for product development or some non-recurring need. The work is meaningful, Dulchinos says, but Jabil has no efficient visibility into, or access to, this kind of short-term work. Fictiv brings this, making distributed manufacturing — or something like it — possible to cost-effectively maintain and pursue.

Distributed manufacturing can be set free of the need for any tooling, but it still requires human knowledge, oversight and communication.

Distributed manufacturing is deviled by other details as well, Dulchinos admits. Even in a network capable of distributing the work easily, the demand does not necessarily find its capacity in the automatic way that a fully digital manufacturing process would seem to imply. People still must make choices. Jabil has assigned a point person to the Fictiv work, someone who watches the opportunities available and judges which ones would be best for Jabil to take on. And while this person has a window into available capacity at all the Jabil sites doing production AM by virtue of the company’s internal production management system, he nevertheless calls and coordinates with managers at the different sites to understand and navigate the conditions they are seeing before sending any work. In other words, distributed manufacturing can be set free of the need for any tooling, but it still requires manufacturing knowledge, still requires oversight, and still calls for human communication between the nodes.

Related Content

Markforged’s Digital Source Platform Enables Printing Parts On-Demand

The platform enables manufacturer-certified parts to be licensed and printed at the point of need.

Read MoreWhat Does Additive Manufacturing Readiness Look Like?

The promise of distributed manufacturing is alluring, but to get there AM first needs to master scale production. GKN Additive’s Michigan facility illustrates what the journey might look like.

Read MoreCumberland Additive: EBM Development and AM Community Among the Benefits at Neighborhood 91

“Digital transparency” is key, says regional director Mark Straszheim, as employees oversee resources in both Pennsylvania and Texas.

Read MoreVideo: Enabling the Digital Inventory with 3D Printing

Würth Additive Group’s Digital Inventory Service (DIS) platform aims to make it easy and secure to store part files in digital inventory, and deploy the data for manufacturing as required. See a demo in this video filmed at IMTS 2024.

Read MoreRead Next

AM at Jabil: From 3D Printing Materials to Distributed Manufacturing

One of the largest manufacturers in the world has made a significant investment in 3D printing — both as a user and an advancer of this technology. Our original reporting dives into the what and why of additive manufacturing at Jabil.

Read More10 Questions About Additive Manufacturing for Production with Jabil’s John Dulchinos

“We’re in this for the long haul,” he says. Here are the challenges facing 3D printing for production, and here are the ways those challenges will be overcome.

Read MoreJabil Prepares for Production AM: It’s Down to the Basics Now

Jabil is getting ready for additive manufacturing to take its place as a production option in addition to conventional processes such as molding and machining. AM can and will fill this role, the company says — the focus now is on controlling cost and assuring quality and reliability.

Read More