Is Direct-Metal Manufacturing Ready for Production?

Not yet, says one manufacturer—but almost. This company is getting its customers ready for the day when additive manufacturing will be much more mainstream.

Rapid Quality Manufacturing (RQM) of Hamilton, Ohio is a production manufacturing business focused on a means of manufacturing that has not even fully arrived yet.

Curt Taylor, RQM’s president, says that this focus leaves the company selective about its customers. Still, plenty of clients have the same vision of the future of manufacturing technology that RQM does.

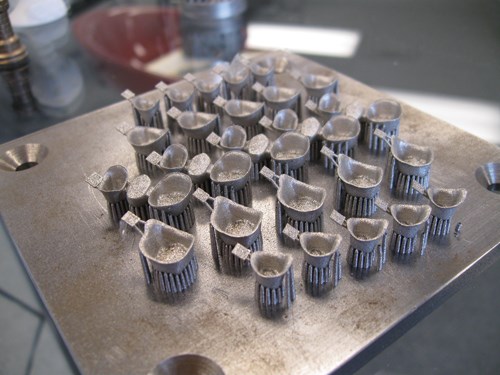

The company specializes in additive manufacturing. It uses DMLS machines—direct metal laser sintering—to “build up” functional metal parts in a layer-by-layer process that uses a laser to fuse and solidify metal powder. RQM’s machines come from German laser sintering equipment maker EOS.

“Pushbutton production” is the ideal of this technology. That is, just input the part geometry data and wait for the machine to “print out” a finished part.

That ideal has not yet been realized, says Mr. Taylor.

In fact, that ideal is, arguably, not even anywhere close.

But the technology and equipment are improving rapidly. The ideal may be far off, but the process is speeding in that direction. And as companies such as RQM develop the disciplines, knowledge and techniques necessary to apply additive metal fabrication effectively in production applications, the day will come that much sooner when additive manufacturing is an easy, accessible and widely accepted option for mass-producing metal parts.

Pilot Production

RQM is part of a larger organization experienced with additive processes. Sister company Morris Technologies began as a prototyping firm, but its role began to change about six years ago. Beyond just design work, Morris was increasingly serving as its customers’ partner in developing mature products and ushering them into production. In 2003, Morris became the first U.S. user of an EOS laser sintering machine. Within two years, Morris became a beta site for the application of EOS’s cobalt chromium material in this machine—a tough metal alloy that was a “game changer,” Mr. Taylor says, because of the range of applications it allowed. This material made it clear that reliable and consistent additive manufacturing of even critical metal parts might soon be a reality.

RQM was founded as a separate company in 2007. Additional EOS machines were purchased and located in a facility apart from Morris, and Mr. Taylor was hired to run the new business. He says dividing product development and manufacturing into separate businesses makes sense for concrete legal and financial reasons (particularly the liability requirements key to medical and aerospace production), but also makes sense simply because of the very different ways the two disciplines use the same equipment. RQM’s mission is to develop efficient and repeatable manufacturing methods around the additive machines. That means personnel need to approach, apply and even think about the equipment in ways that look much different from the sister company’s work of product development.

Today, RQM serves customers through “pilot production.” The term means very different things in different cases—suggesting a production quantity that is, at least, “more than one and less than one million,” Mr. Taylor says. In nearly all cases, though, the pilot production involves refining both the production process and the design of the part so that additive manufacturing can produce the part consistently, with as few follow-up steps as possible. The company works with customers to explore what additive manufacturing can accomplish for their parts today, while also laying the foundation for what additive manufacturing will be able to accomplish for similar parts tomorrow.

Machining Required

That need for “follow-up steps” is an underappreciated aspect of DMLS that points to why it is not—and might never be—merely “pushbutton production.”

A critical part made from direct metal laser sintering is likely to require heat treating or HIPping, and will also almost certainly need some type of deburring or finishing process in order to give the layered component a smooth surface. In addition, any high-value, functional DMLS part will probably have to be machined.

While additive manufacturing is often seen as the competitor and mirror image to the “subtractive” process of machining, the reality is that additive manufacturing of metal parts is more accurately thought of as a near-net process in which machining still plays a crucial role. Similar to a casting, DMLS parts are often made with an extra stock envelope to ensure favorable internal stresses, with the extra stock later removed through CNC machining. Certain fine details of the part might also be produced through EDM. RQM relies on the machining capabilities of sister company Morris for this sort of work. While touring Morris’s shop, one additive manufactured part I happened to see had radial channels all along the OD, but not in the pre-machined state. The part’s built-in channels were revealed only as the part was turned on a lathe so that the OD stock envelope was removed.

The reason to go through this multi-operation process involving laser sintering, machining, and other steps is not because it can produce a part more efficiently than other methods. Often it can’t. Instead, the reason to choose this method is the design freedom that DMLS allows. As opposed to machining, casting or molding, building the part in precisely controlled layers enables manufacturers to achieve geometric forms that in many cases could not be produced in any other way.

Conformal cooling channels illustrate the promise of this. One of the earliest applications EOS found for the additive metal technology was building molds with cooling channels that conform to the shape of the molded part. Needless to say, cooling holes made with the straight motion of an external drill would not be able to follow the final form so closely.

Beyond this mold tooling, RQM has discovered various niches in which additive metal manufacturing is production-ready today. It now applies DMLS for mass production in applications that include:

• Dental copings and bridges. Truly a “mass customization” application, additive manufacturing of dental implants makes it possible to generate a run of parts in which every distinct piece is customized to the particular geometry of some individual patient. The geometry file input to the machine is different for every production run, and serial numbers linking implants to patients are part of the individual geometry of each separate piece.

• Medical instruments. With additive manufacturing, surgical tools don’t have to be locked into rigid designs. The same tool can be cost-effectively tailored to fit particular surgeons’ preferences.

• Art and jewelry. Geometrically complex ornamentation is also an obvious choice for the additive process—particularly when the manufactured quantity of each individual design is small.

Still, the more promising applications of additive manufacturing involve parts that are even more critical than these. Largely because of their critical nature, though, the additive process has further to go in these cases to prove itself reliable, and win certification for mature production. RQM is currently working on pilot production of complex, high-value parts including:

• Surgical implants, in which the implant geometry is individually adjusted for minute details of the particular patient’s geometry; as well as

• Gas turbine engine components. Here, the promise of conformal cooling channels is potentially even more valuable than it is in mold making. Building precisely contoured channels into the part gives engineers the freedom to optimize efficiency by fine-tuning the design to improve airflow and thermodynamics.

“We work with customers who ‘get it,’” Mr. Taylor says. The statement isn’t cavalier, but instead is an inevitable consequence of the state of the technology that RQM is working to advance. For parts already being manufactured through some existing process, DMLS is unlikely to be cost-competitive.

“Someone who comes to us and says, ‘Here’s my part; what’s your quote?’ is not asking the right question,” he says. A request of this nature doesn’t speak to the ways RQM can add value.

Instead, the right question would instead be something like this: Here is the part that lets me solve my problem today. What kind of part could DMLS give me that would let me solve my problem in a better way tomorrow? All of RQM’s committed customers are working with the company to explore the answer to some variation on that question.

Process Knowledge

In turn, RQM is working with EOS. Further development of the direct-metal technology itself will ultimately be vital to fully realizing mature production of critical parts. Over time, DMLS technology has become considerably more precise in terms of geometric repeatability. Now, the area in greater need of improvement is part-to-part repeatability of material properties. That is why RQM’s inspection technology includes not just the 3D geometric metrology tools of a machine shop, but also a mechanical testing system and equipment for particle analysis of the raw material. Using tools such as these, the company is exploring what cause-and-effect relationships govern the final performance and properties of the part, so the information can be shared with EOS. The knowledge will allow the technology developer to identify and more finely control the parameters that most need to be controlled in order to make DMLS production-ready for a broader range of applications.

RQM, meanwhile, applies its knowledge of the many variables it does understand to streamline additive manufacturing processes today. A customer typically works with some combination of RQM and Morris to develop precisely the right design for a given part’s functional needs. Then, RQM analyzes the part and works with the customer to further refine the design for manufacturing. The part geometry issues that might be explored include:

• Are wall thicknesses too thin?

• Are hole sizes too small or too large for DMLS to hold the necessary tolerances?

• Are radii big enough to avoid cracking during secondary operations?

• How much stock should be added, and where, for the purposes of internal stresses?

Even the orientation of the part is a subtly important point. The simple question of the direction of the form during laser sintering can have dramatic consequences for how much extra work is needed after finishing additive manufacturing.

In short, far from just “printing a part,” additive manufacturing demands process expertise that is every bit as sophisticated as what is required for CNC machining or any other precision manufacturing process.

Yet RQM believes that developing the process expertise now will better prepare it for the day—and prepare its customers for the day—when additive manufacturing fully and inevitably takes its place alongside these other proven methods for producing high-value parts.

Related Content

How Machining Makes AM Successful for Innovative 3D Manufacturing

Connections between metal 3D printing and CNC machining serve the Indiana manufacturer in many ways. One connection is customer conversations that resemble a machining job shop. Here is a look at a small company that has advanced quickly to become a thriving additive manufacturing part producer.

Read MoreHow Norsk Titanium Is Scaling Up AM Production — and Employment — in New York State

New opportunities for part production via the company’s forging-like additive process are coming from the aerospace industry as well as a different sector, the semiconductor industry.

Read MoreAdditive Manufacturing Is Subtractive, Too: How CNC Machining Integrates With AM (Includes Video)

For Keselowski Advanced Manufacturing, succeeding with laser powder bed fusion as a production process means developing a machine shop that is responsive to, and moves at the pacing of, metal 3D printing.

Read MoreWith Electrochemical Additive Manufacturing (ECAM), Cooling Technology Is Advancing by Degrees

San Diego-based Fabric8Labs is applying electroplating chemistries and DLP-style machines to 3D print cold plates for the semiconductor industry in pure copper. These complex geometries combined with the rise of liquid cooling systems promise significant improvements for thermal management.

Read MoreRead Next

3D Printed Polymer EOAT Increases Safety of Cobots

Contract manufacturer Anubis 3D applies polymer 3D printing processes to manufacture cobot tooling that is lightweight, smooth and safer for human interaction.

Read MoreCrushable Lattices: The Lightweight Structures That Will Protect an Interplanetary Payload

NASA uses laser powder bed fusion plus chemical etching to create the lattice forms engineered to keep Mars rocks safe during a crash landing on Earth.

Read MoreAlquist 3D Looks Toward a Carbon-Sequestering Future with 3D Printed Infrastructure

The Colorado startup aims to reduce the carbon footprint of new buildings, homes and city infrastructure with robotic 3D printing and a specialized geopolymer material.

Read More