Contract Shop Invests in Hybrid Manufacturing for Survival and Growth

An Ontario manufacturer sees hybrid manufacturing as a means for survival.

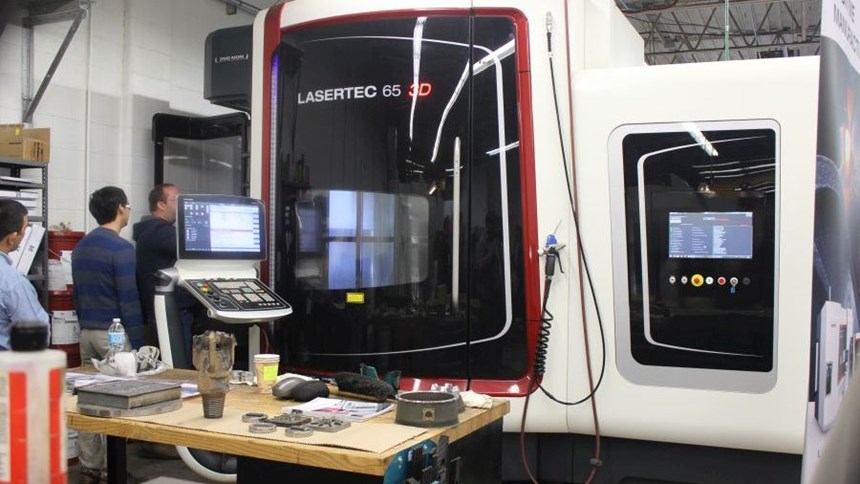

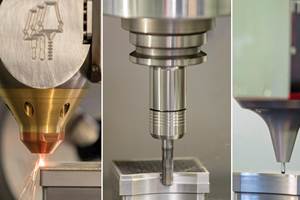

PTooling may not be the place you’d expect to find the first installation of a cutting-edge hybrid manufacturing system. The contract manufacturer in Amherstburg, Ontario, is a small family-owned company that has served Canada’s oilfield industry since 1999, relying on equipment such as its CNC turning centers and vertical machining center. But today the company is the owner of the first DMG MORI Lasertec 3D 65 hybrid milling and laser deposition machine to have been purchased in North America. As to why PTooling decided to make this leap into hybrid manufacturing, the company’s president, Marv Fiebig, says: “Survival.”

Invest to Survive

Leveraging advanced manufacturing technology is a strategy that has helped PTooling get through difficult times in the past. When the market went south in 2008, Fiebig realized that his company would have to differentiate itself from the other “mom and pop” shops also serving the oilfield industry in order to stay in business. The solution then was to modify the supply chain and invest in new, advanced equipment. The shop purchased a coordinate measuring machine and ramped up its quality department. These changes helped PTooling survive the downturn by setting it apart from its competitors.

With Canada’s oilfield industry again in a slump since mid-2014, PTooling’s purchase of the Lasertec hybrid is the next step in its evolution, as a means to diversify its operations and bring benefits to existing customers. Additive manufacturing had seemed like a move in the right direction for some time, but the company was waiting for the right metal AM machine to come along. According to Fiebig, powder bed machines didn’t have build envelopes large enough for the company’s needs. Other systems were rejected because of restrictions on the types and numbers of materials that could be used.

The Lasertec 65 3D won out for several reasons. Fiebig likes the fact that it is a hybrid machining center—not just a dedicated AM system. This allows PTooling to mill parts aggressively, like it would in any other machining center; in fact, the machine is sometimes used as a spare mill if its AM capabilities are not required. And when the additive head is used on a hybrid project, parts can be easily milled as they are built, even after each layer if necessary.

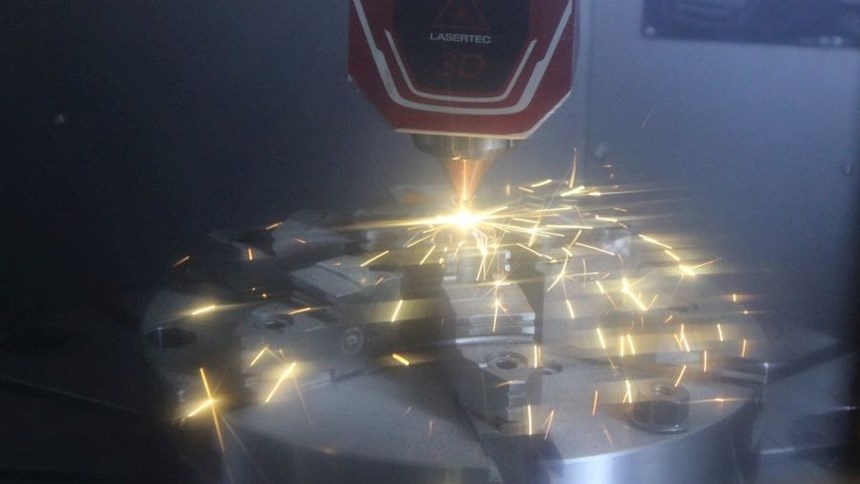

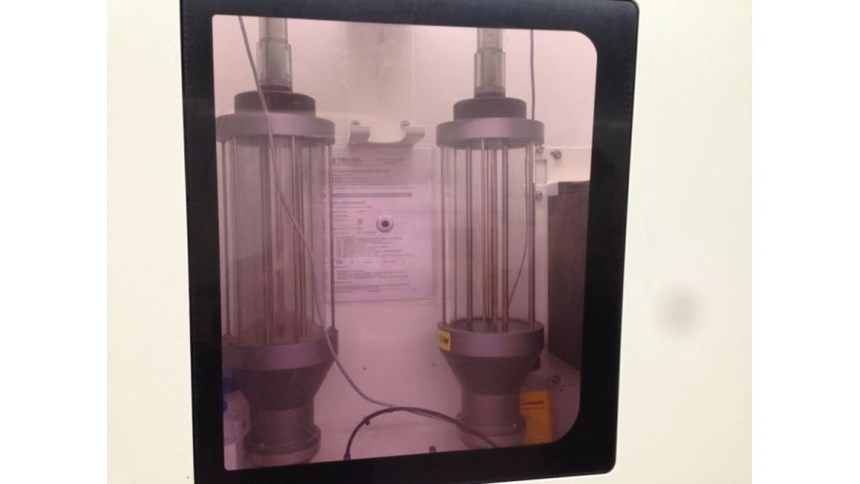

In addition, the Lasertec’s laser deposition strategy is better suited to PTooling’s needs than a powder bed system, says Fiebig. The machine’s powder-fed head not only makes a larger work envelope possible, which is necessary to accommodate larger parts such as oilfield components, but the material deposition also enables building up a part essentially from nothing, rather than starting with a large volume of powder. The result is lower startup cost and less waste. Furthermore, the Lasertec’s dual material hoppers make it possible to switch between materials in about one minute, versus the time it would take to safely clean out a powder bed machine and restock it. The dual hoppers even enable the use of two different materials within the same part, including blending the materials together.

New Possibilities

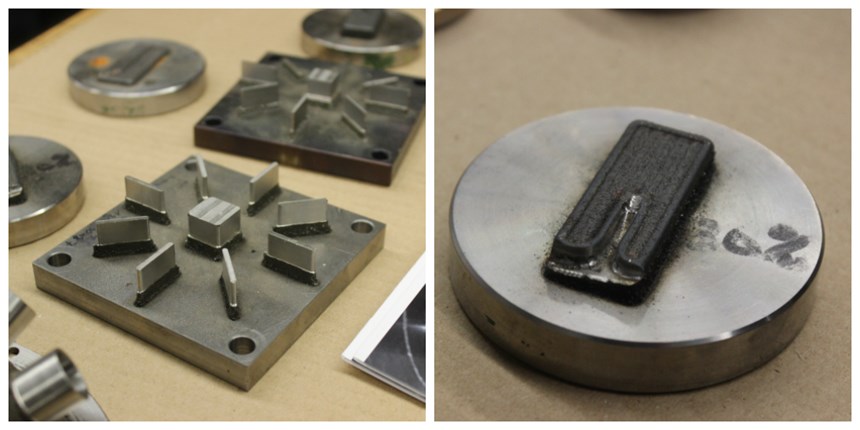

Now that the machine has been running for several months, the employees at PTooling are excited about what it can do. Early customer applications have included a mold core and cavity that was laser deposited from the bottom up with conformal cooling channels designed to encourage turbulence in the cooling fluid (for better heat transfer), and an oilfield drill with a laser-cladded exterior layer meant to increase its durability.

On the whole, PTooling is finding that customers are eager to work with the company and see if their parts are suitable for this kind of hybrid manufacturing. In fact, Fiebig says that for the first time ever, new customers are calling him (instead of the other way around) now that the word is out about the machine. It’s been helping the company gain traction with big-name oilfield companies, as well as diversify into new industries such as aerospace.

PTooling is also in a position to teach fellow manufacturers about hybrid technology. According to Fiebig, additive is challenged right now because people like the end result—a mold that cools faster, a component that’s lighter—but aren’t necessarily willing to sign off on a purchase order for a machine. There’s fear, he says. And that fear is somewhat justified. He readily admits that bringing an additive or hybrid machine on board is an expensive proposition, and the tasks necessary to define and refine the process take time.

“But we’re doing it, and we’re not regretting it,” he says. That fearless attitude has helped position PTooling at what Fiebig calls the “bleeding edge” of its industry. His advice to other manufacturers: “If you’re contemplating this type of machinery, you’re not going to make a mistake in pursuing it. If you’re contemplating a project that would use this type of technology, don’t be afraid of it.”

Related Content

Video: Hybrid Manufacturing Without Melting: Hermle’s Metal Powder Application (MPA) Process

The Metal Powder Application (MPA) process uses cold spray to apply metal to an existing workpiece. Because the material deforms rather than melts, MPA opens new possibilities for functional grading and other multimaterial applications.

Read MoreVideo: Robot Machining Will Complement Robot DED

Robots can do additive manufacturing. Can they do hybrid manufacturing? Precision milling of metal using a robot offers this promise.

Read MoreVideo: For 3D Printed Aircraft Structure, Machining Aids Fatigue Strength

Machining is a valuable complement to directed energy deposition, says Big Metal Additive. Topology-optimized aircraft parts illustrate the improvement in part performance from machining as the part is being built.

Read More5 Points You Might Not Know About Hybrid CNC Machine Tools

Hybrid Manufacturing Technologies’ co-founder describes the role of hybrid additive manufacturing machines, and explores their possibilities related to heat treating, multimaterial tooling and making parts with embedding sensing.

Read MoreRead Next

Alquist 3D Looks Toward a Carbon-Sequestering Future with 3D Printed Infrastructure

The Colorado startup aims to reduce the carbon footprint of new buildings, homes and city infrastructure with robotic 3D printing and a specialized geopolymer material.

Read MoreProfilometry-Based Indentation Plastometry (PIP) as an Alternative to Standard Tensile Testing

UK-based Plastometrex offers a benchtop testing device utilizing PIP to quickly and easily analyze the yield strength, tensile strength and uniform elongation of samples and even printed parts. The solution is particularly useful for additive manufacturing.

Read MorePostprocessing Steps and Costs for Metal 3D Printing

When your metal part is done 3D printing, you just pull it out of the machine and start using it, right? Not exactly.

Read More

.jpg;width=70;height=70;mode=crop)